Method and device for improving yarn wet joint wear resistance

A technology of wear resistance and yarn, which is applied in the field of methods and devices for improving the wear resistance of wet joints of yarns, can solve problems such as the inability to guarantee the joint quality enhancement effect, good quality, and no consideration of nano-suspensions, etc., to achieve automation Easy operation, easy operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

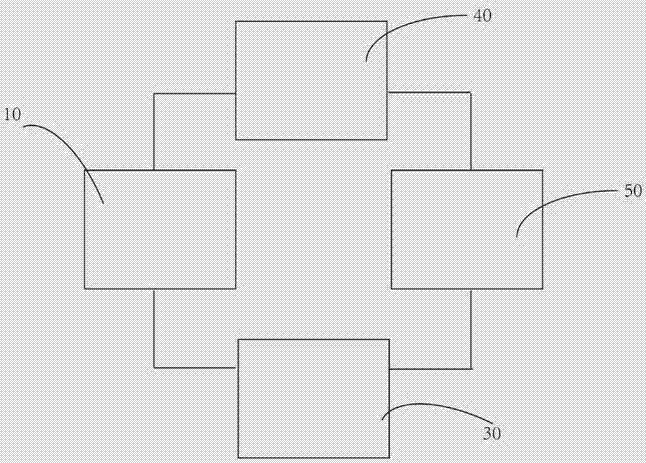

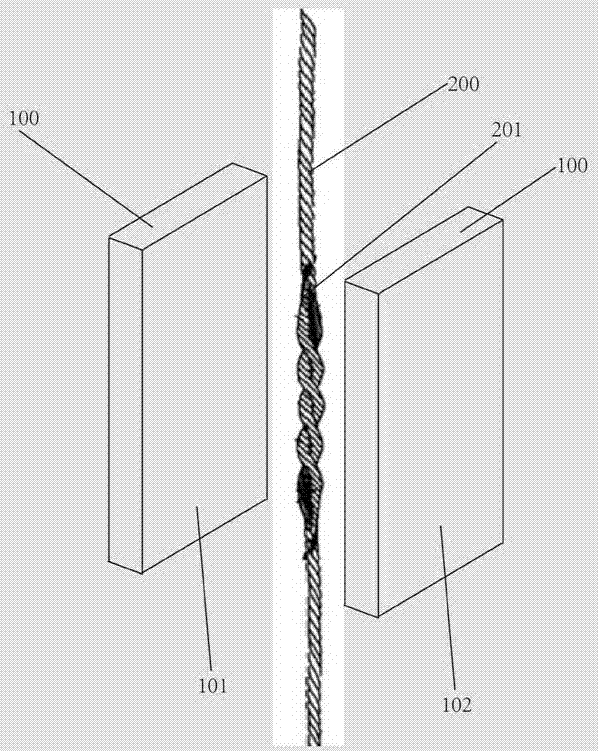

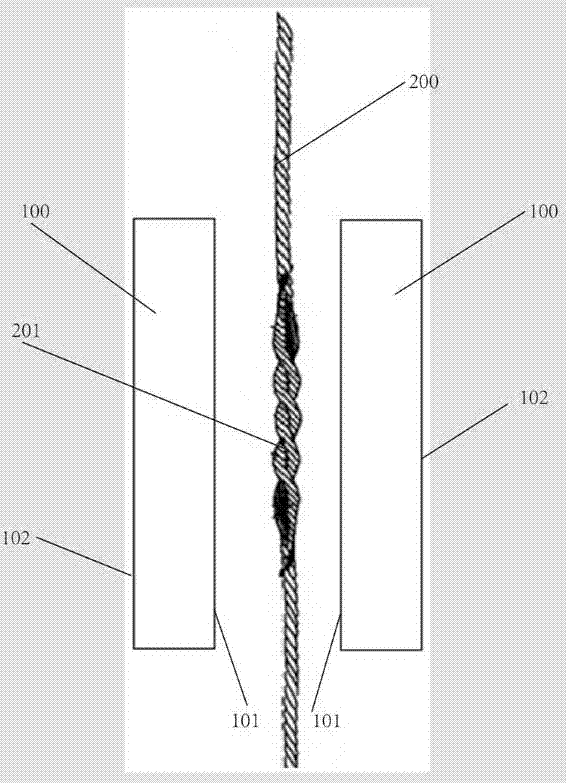

[0034] A device for improving the wear resistance of yarn wet joints, see Figure 1-Figure 3 As shown, it includes a spray liquid reservoir 50 , a heat treatment component 10 and a control component 30 . Both the spray liquid reservoir 50 and the heat treatment unit 10 are connected to the control unit 30 .

[0035] The spray liquid in the spray liquid reservoir 50 is water, and the water contains colloidal particles, powder particles, emulsifiers and dispersants. A stirrer (not shown in the figure) is also provided inside the spray liquid storage 50, and the control component is connected to the stirrer to drive the stirrer to rotate. The function of the agitator is to uniformly disperse the spray liquid, colloidal particles, powder particles and emulsifier in the spray liquid storage 50 to avoid precipitation.

[0036] The control unit 30 is connected to the spray liquid storage 50 for extruding the spray liquid from the spray liquid storage 50, and the control unit 30 is ...

Embodiment 2

[0048] A method for improving the wear resistance of yarn wet joints, comprising the steps of:

[0049] After the yarn 200 is broken, the control part 30 controls the spray liquid storage device 50 to spray the spray liquid to the yarn joint 201 of the yarn 200 through its liquid outlet. The spray liquid ejected from the liquid outlet includes colloidal particles, powder particles and emulsifiers.

[0050] Wherein, the colloidal particles are polyurethane colloidal particles. The powder particles are polyvinyl alcohol or epoxy resin. The emulsifier is OP emulsifier.

[0051] Both colloidal and powder particles have a size range of 100 nm. The spray liquid storage device 50 sprays the spray liquid to the yarn joint 201 of the yarn 200 through its liquid outlet. The droplet diameter of the spray liquid is 0.1 mm, and the distance between the droplets on the yarn joint 201 is 0.3mm.

[0052] The control unit 30 controls the two heat treatment splints 100 of the heat treatmen...

Embodiment 3

[0058] The method for improving the wear resistance of yarn wet joints comprises the following steps:

[0059] After the yarn 200 is broken, the control part 30 controls the spray liquid storage device 50 to spray the spray liquid to the yarn joint 201 of the yarn 200 through its liquid outlet. The spray liquid ejected from the liquid outlet includes colloidal particles, powder particles and emulsifiers.

[0060] Wherein, the colloidal particles are polyurethane colloidal particles. The powder particles are polyvinyl alcohol or epoxy resin. The emulsifier is OP emulsifier.

[0061] Both colloidal and powder particles have a size range of 100 nm. The spray liquid storage device 50 sprays the spray liquid to the yarn joint 201 of the yarn 200 through its liquid outlet. The droplet diameter of the spray liquid is 3 mm, and the distance between the droplets on the yarn joint 201 is 20 mm. .

[0062] The control unit 30 controls the two heat treatment splints 100 of the heat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com