Auxiliary bonding device for yarn splicing of winding machine and method of use thereof

A technology of bonding device and yarn machine, applied in the field of weaving processing, can solve the problems of weak wear resistance of yarn joints, easy to break, not fully cohesive, etc., to achieve improved yarn wear resistance, firm joints, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

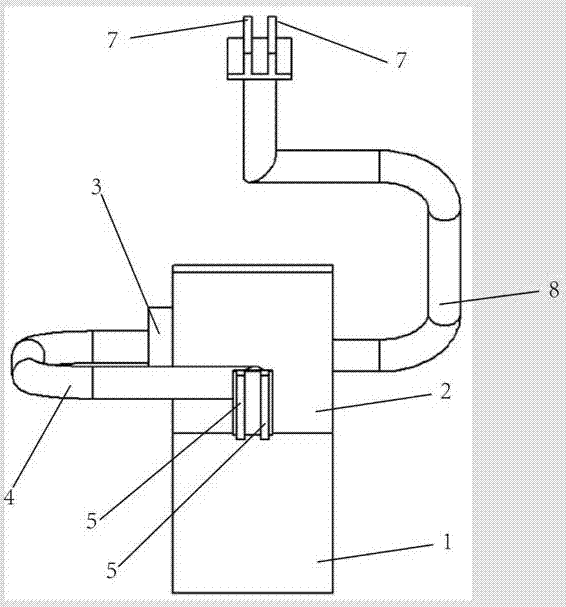

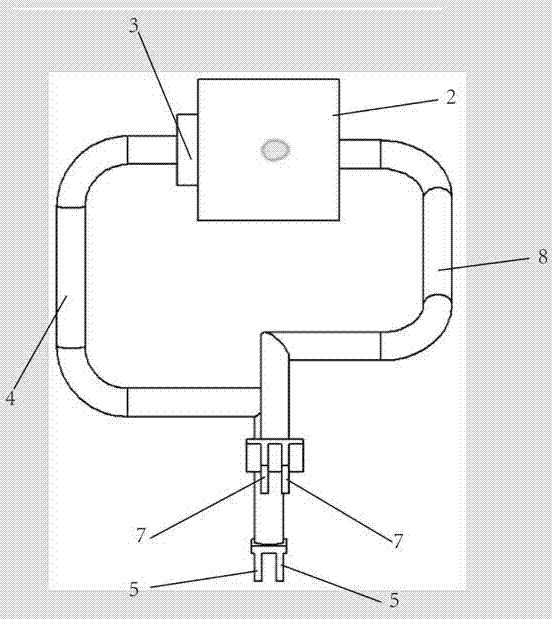

[0032] This embodiment provides an auxiliary bonding device for yarn joints of a winder.

[0033] An auxiliary bonding device for yarn joints of a winding machine, see Figure 1-Figure 4 As shown, it includes a storage part 2, a signal receiving part 3, a material channel 4, a printing plate 5, a heat treatment part, a driving part and a transmission part, the signal receiving part 3 is installed in the storage part 2, and the transmission Components are connected to the storage part 2 for moving the storage part 2; the storage part 2 is supported by metal, plastic or polymer material, and the length of the storage part 2 is 100-500mm and the width is 50-200mm, the height is level with the splicer position of the winding machine. The function of the signal receiving part 3 is to receive the knotting signal of the splicer.

[0034] The length of the printing plate 5 is 30-80mm, and the width is 2-10mm. The printing plate 5 is connected to the storage part 2 through the materi...

Embodiment 2

[0043] This embodiment provides a method for using an auxiliary bonding device for yarn joints of a winder.

[0044] A method for using an auxiliary bonding device for yarn joints of a winding machine, comprising the following steps:

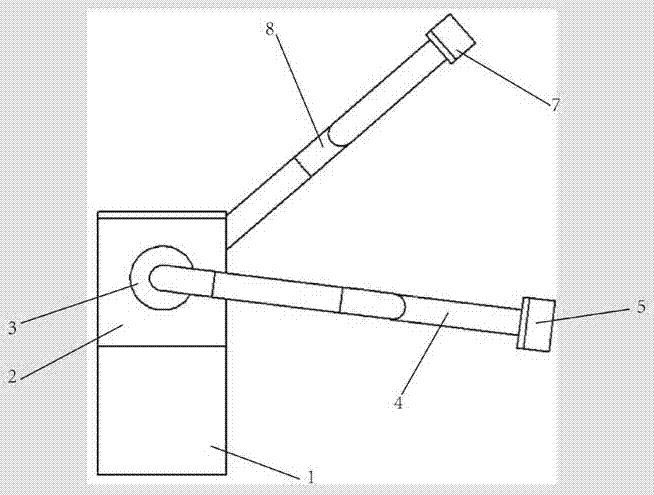

[0045] The transmission part makes the winding machine yarn splicing auxiliary bonding device (mobile base 1) move around the front of the winding machine through the transmission belt, and the mobile signal receiving part 3 on the storage part 2 receives the broken spindle signal of the winding machine, The transmission part moves the yarn joint auxiliary bonding device (moving base 1) of the winding machine to the yarn joint 91 of the spindle splicer;

[0046] The first driving element drives the material channel 4 to rotate around the material storage part 2 to the yarn joint, and squeezes the material channel 4 so that the glue in the material storage part 2 passes through the material channel 4 and the printing plate 5. The material outlet...

Embodiment 3

[0052] This embodiment provides a method for using an auxiliary bonding device for yarn joints of a winder.

[0053] A method for using an auxiliary bonding device for yarn joints of a winding machine, comprising the following steps:

[0054] The transmission part makes the winding machine yarn splicing auxiliary bonding device (mobile base 1) move around the front of the winding machine through the transmission belt, and the mobile signal receiving part 3 on the storage part 2 receives the broken spindle signal of the winding machine, The transmission part moves the yarn joint auxiliary bonding device (moving base 1) of the winding machine to the yarn joint 91 of the spindle splicer;

[0055] The first driving element drives the material channel 4 to rotate around the material storage part 2 to the yarn joint, and squeezes the material channel 4 so that the glue in the material storage part 2 passes through the material channel 4 and the printing plate 5. The discharge port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com