Rabble blade for excavating railway ballast

A technology of rake teeth and ballast, which is applied in the field of excavation devices of screen cleaners, can solve problems such as failure of connection between rake teeth and excavation chains, inconvenient disassembly and assembly, and achieve the effects of improving service life, preventing eccentric wear, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

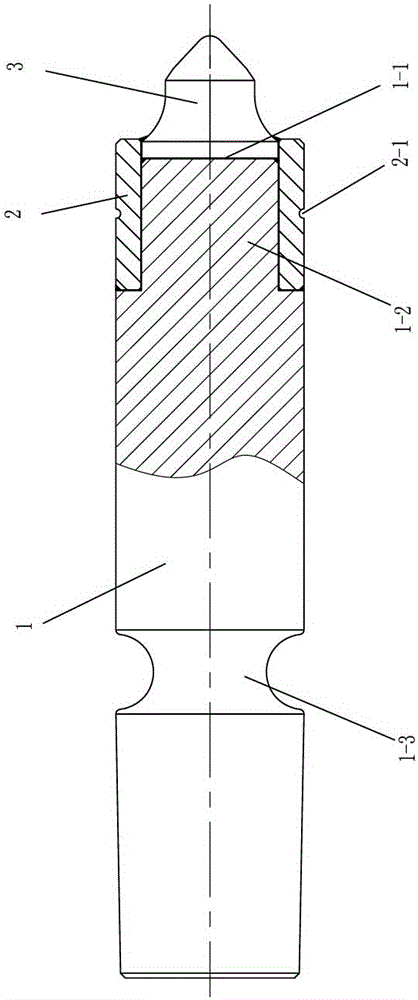

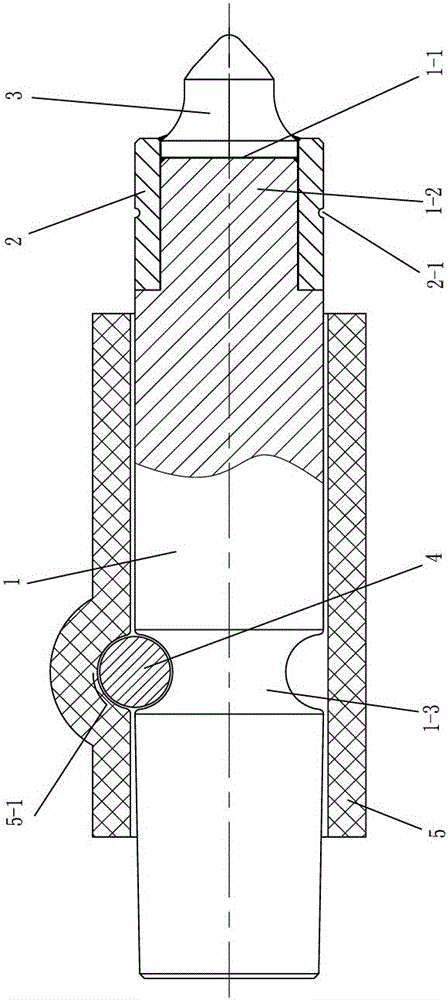

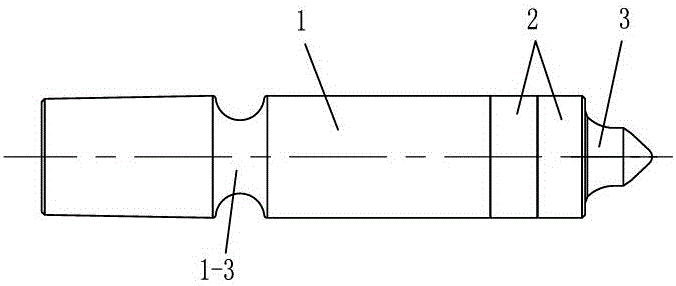

[0024] Such as figure 1 , 2 As shown in the first embodiment of the present invention, a ballast digging harrow includes a knife handle 1, a cemented carbide wear-resistant part 2 and a cemented carbide cutter head 3. The head of the cutter handle 1 has a neck 1-2 and the front end face 1-1, the hard alloy wear-resistant part 2 is fixedly connected to the neck 1-2, the hard alloy cutter head 3 is fixedly connected to the front end face 1-1, and the hard alloy The top surface of the high-quality alloy wear-resistant part 2 exceeds the front end surface 1-1 of the knife handle 1, and the handle body of the knife handle 1 is provided with a pin installation groove 1-3.

[0025] Such as figure 1 , 2 As shown, the hard alloy wear-resistant part 2 and the neck 1-2 of the shank 1 are welded or interference-connected, and the hard alloy bit 3 and the front end surface 1-1 of the shank 1 are welded.

[0026] Such as figure 1 , 2 As shown, the hard alloy wear-resistant part 2 is an integral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com