Combined treatment method for dehumidification and vacuum preloading of dredger fill and slurry flocculation

A technology of combined treatment and dredging of soil, applied in the fields of soil protection, construction, infrastructure engineering, etc., can solve the problems of low water reduction rate, inability to achieve uniform mixing, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

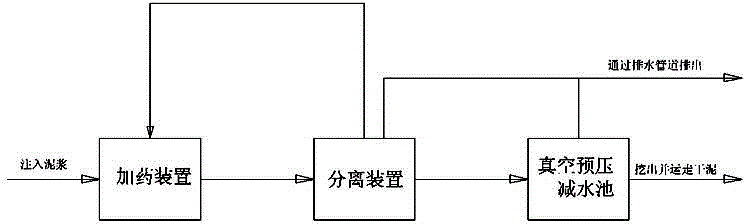

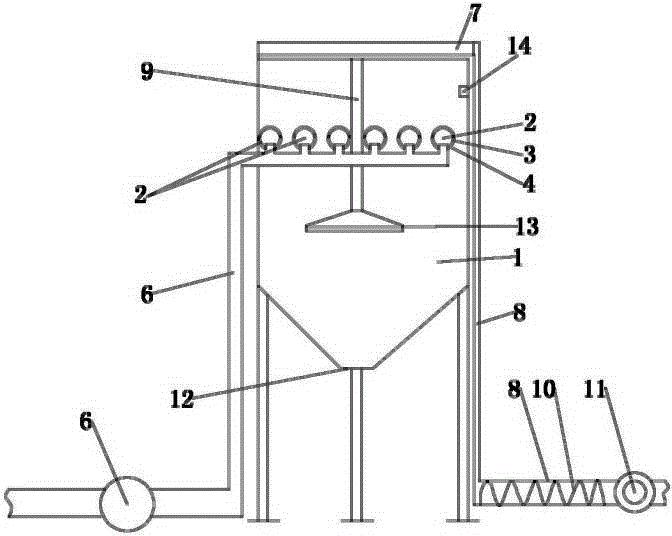

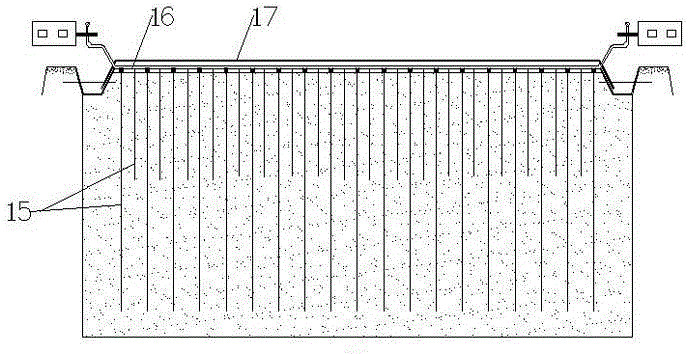

[0012] refer to figure 1 , figure 2 , image 3 As shown, the dredging fill and mud flocculation dehydration vacuum preloading combined treatment method provided by the first embodiment of the present invention includes the following steps: A. Inject mud, and add flocculant and / or lime to the mud, generally add flocculation The flocculant and / or lime will be carried out in the dosing device composed of the mud tank, the mud tank is connected with the dosing tank and the drug delivery device, the flocculant and / or lime will be mixed with water in the dosing tank, and sent by the drug delivery device In the mud pool, a stirring device can also be set in the mud pool; or, the mud pool can not be provided, and the mixture in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com