Charging circuit used for mobile power supply and mobile power supply

A charging circuit and mobile power technology, applied in the direction of battery circuit devices, circuit devices, collectors, etc., can solve problems that affect the performance and reliability of mobile power sources, large power dissipation of mobile power sources, and the impact of electronic device performance, etc., to achieve improved charging Efficiency, Faster Charging, Ease of Implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

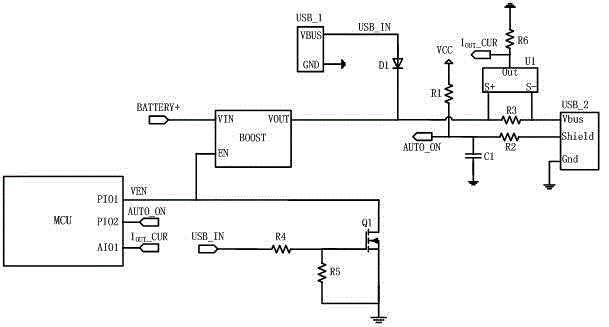

[0029] Embodiment one, see figure 1 As shown, in this embodiment, a charging interface USB_1 for external input power supply and a discharge interface USB_2 for external load are designed on the mobile power supply. The discharge interface USB_2 can be provided with one channel or multiple channels. In order to enable the input power supply USB_IN connected through the charging interface USB_1 to directly charge the external load, this embodiment connects the power supply pin VBUS of the charging interface USB_1 with the power supply pin Vbus of the discharge interface USB_2, so that the input power supply VBUS_IN can be connected to After being connected to the mobile power supply, it is directly transmitted to the external load through the power pin Vbus of the discharge interface USB_2 to charge it. In order to prevent the internal current of the mobile power supply from being fed back to the input power supply VBUS_IN, this embodiment connects an anti-reverse bias diode D...

Embodiment 2

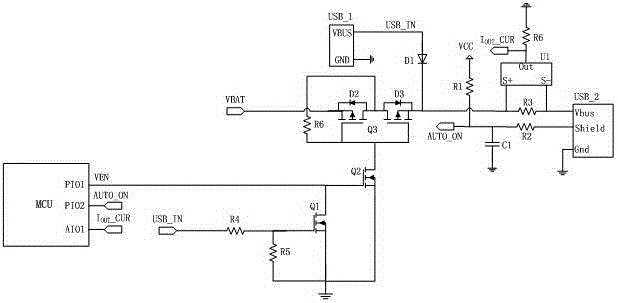

[0040] Embodiment two, see figure 2 As shown, in this embodiment, the charging interface USB_1 for external input power and the discharge interface USB_2 for external load are also designed on the mobile power supply. After the power supply pin VBUS of the charging interface USB_2 is connected in series with the anti-reverse bias diode D1, the power supply pin Vbus of the discharge interface USB_2 is connected. When the input power supply USB_IN is connected to the charging interface USB_1, the load inserted into the discharge interface USB_2 is directly Charge.

[0041] In order to control the built-in battery of the mobile power supply to stop charging the external load when the input power supply USB_IN is connected to the charging interface USB_1, this embodiment first designs a switch in the path where the battery is connected to the power pin Vbus of the discharge interface USB_2 circuit, the switch circuit can be formed by connecting two PMOS transistors, or directly ...

Embodiment 3

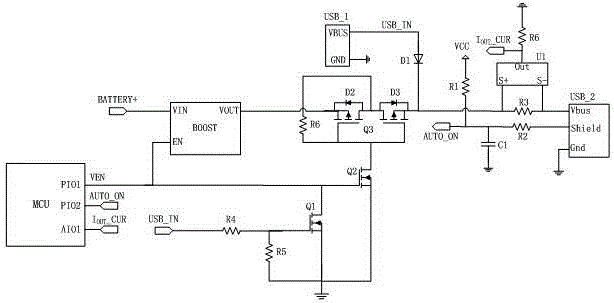

[0049] Embodiment three, see image 3 As shown, in this embodiment, the charging interface USB_1 for external input power and the discharge interface USB_2 for external load are also designed on the mobile power supply. After the power supply pin VBUS of the charging interface USB_2 is connected in series with the anti-reverse bias diode D1, the power supply pin Vbus of the discharge interface USB_2 is connected. When the input power supply USB_IN is connected to the charging interface USB_1, the load inserted into the discharge interface USB_2 is directly Charge.

[0050] In order to control the built-in battery of the mobile power supply to stop charging the external load when the input power supply USB_IN is connected to the charging interface USB_1, this embodiment designs a boost in the path where the battery is connected to the power pin Vbus of the discharge interface USB_2 The circuit BOOST and a switch circuit, the boost circuit BOOST can be formed by discrete compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com