Festival decoration lamp string with multiple parallel wires and preparation method of festival decoration lamp string

A technology for decorative lamps and manufacturing methods, which is applied to lighting devices, lighting and heating equipment, components of lighting devices, etc., and can solve the problems of increased power dissipation of LED lamps, affecting the production efficiency of light strings, and burning out LED lamps, etc. , to achieve the effect of good consistency, cost reduction and consistent brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

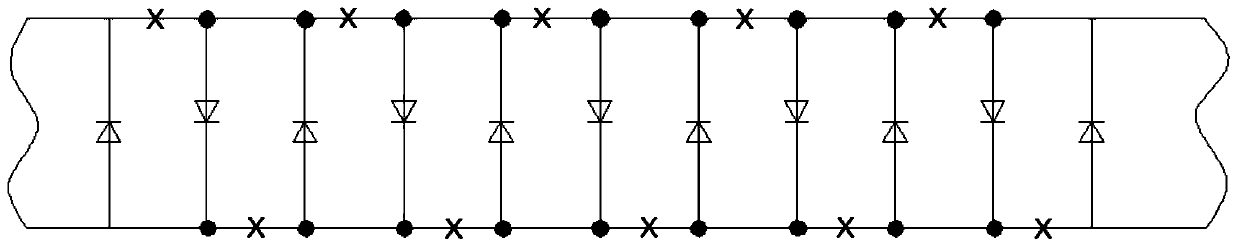

[0045] see figure 1 As shown, a method for preparing a three-parallel wire festive decorative light string suitable for 3V, 110V, and 220V power supplies includes the following steps:

[0046]Step 1. Prepare the conductor coil and place it on the pay-off wheel. The free end of the conductor coil is wound on the pay-off swing rod. The pay-off swing rod sends the free end of the conductor coil into the stripping mechanism. The conductor coil is stripped at equal intervals The wire mechanism is divided into a positive electrode wire and a negative electrode wire, and the positive electrode wire and the negative electrode wire are crushed and peeled by the peeling mechanism so that the positive electrode wire and the negative electrode wire are exposed to form a positive electrode solder joint and a negative electrode solder joint;

[0047] Step 2. Apply solder paste on the surface of the positive solder joint and the negative solder joint through a tin spotting machine;

[0048...

Embodiment 2

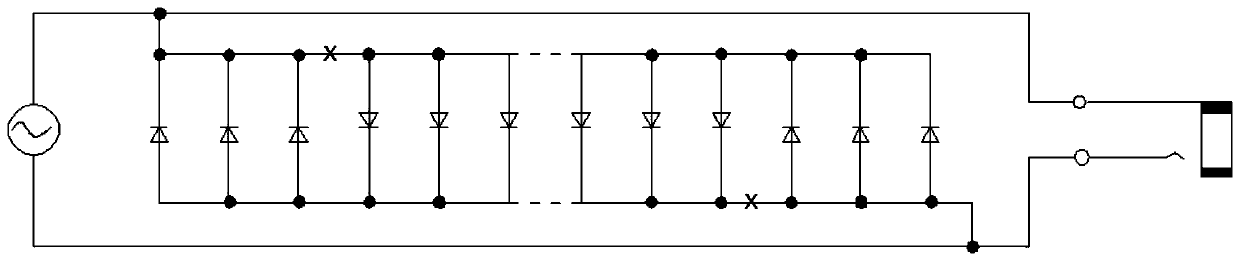

[0055] see figure 2 As shown, a method for preparing a four-parallel wire festive decorative light string suitable for 3V, 110V, and 220V power supplies includes the following steps:

[0056] Step 1. Prepare the conductor coil and place it on the pay-off wheel. The free end of the conductor coil is wound on the pay-off swing rod. The pay-off swing rod sends the free end of the conductor coil into the stripping mechanism. The conductor coil is stripped at equal intervals The wire mechanism is divided into a positive electrode wire and a negative electrode wire, and the positive electrode wire and the negative electrode wire are crushed and peeled by the peeling mechanism so that the positive electrode wire and the negative electrode wire are exposed to form a positive electrode solder joint and a negative electrode solder joint;

[0057] Step 2. Apply solder paste on the surface of the positive solder joint and the negative solder joint through a tin spotting machine;

[0058...

Embodiment 3

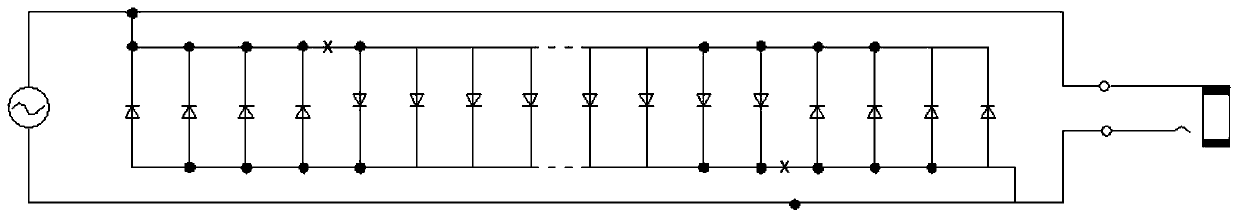

[0065] see image 3 As shown, a method for preparing a four-parallel wire festive decorative light string suitable for 3V, 110V, and 220V power supplies includes the following steps:

[0066] Step 1. Prepare the conductor coil and place it on the pay-off wheel. The free end of the conductor coil is wound on the pay-off swing rod. The pay-off swing rod sends the free end of the conductor coil into the stripping mechanism. The conductor coil is stripped at equal intervals The wire mechanism is divided into a positive electrode wire and a negative electrode wire, and the positive electrode wire and the negative electrode wire are crushed and peeled by the peeling mechanism so that the positive electrode wire and the negative electrode wire are exposed to form a positive electrode solder joint and a negative electrode solder joint;

[0067] Step 2. Apply solder paste on the surface of the positive solder joint and the negative solder joint through a tin spotting machine;

[0068]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com