LED drive circuit

A technology of LED drive and circuit, applied in the direction of lamp circuit layout, electric light source, lighting device, etc., can solve the problems of high working voltage, affecting the stability of driving circuit, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

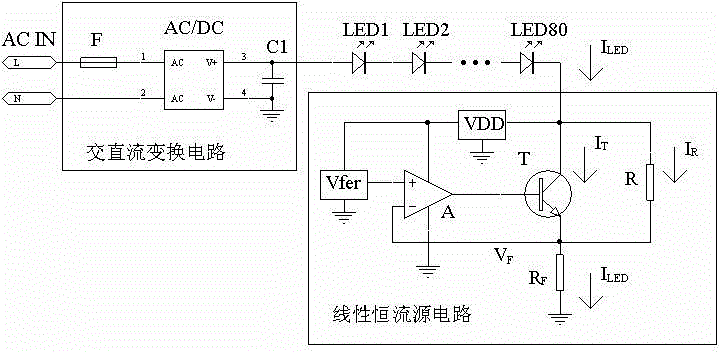

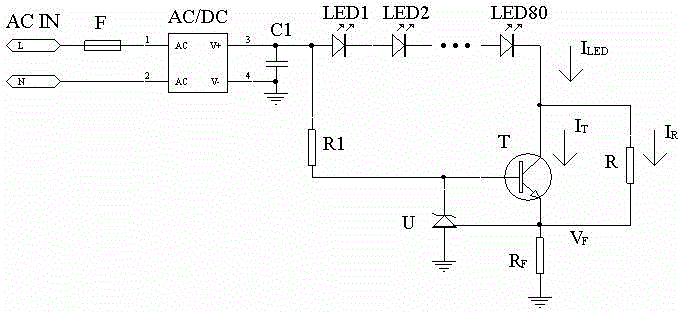

[0015] figure 2 It is an embodiment of the LED driving circuit according to the present invention. The reference reference voltage and the operational amplifier are replaced by a parallel three-terminal voltage regulator TL431. The characteristic of this circuit is that the output current stability accuracy is relatively high.

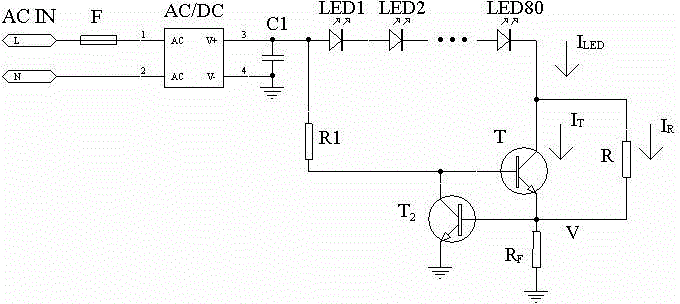

[0016] image 3 It is another embodiment of the LED driving circuit according to the present invention. This is a low cost circuit that uses all bipolar transistors. The characteristic of this circuit is that the output current has a negative temperature coefficient. This is very beneficial to reduce the light attenuation of the LED of the light source module.

[0017] Figure 4 It is another embodiment of the LED driving circuit according to the present invention. Among them, IC is a high-voltage linear constant current integrated circuit. In this circuit, since the constant current output adjustment tube, current detection and operational amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com