Multi-stator traction high-speed maglev train system

A technology for maglev trains and traction systems, which is applied in the field of multi-stator traction high-speed maglev train systems, and can solve the problems of high cost, high construction cost, and defects in contact power supply methods for medium and low-speed maglev trains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

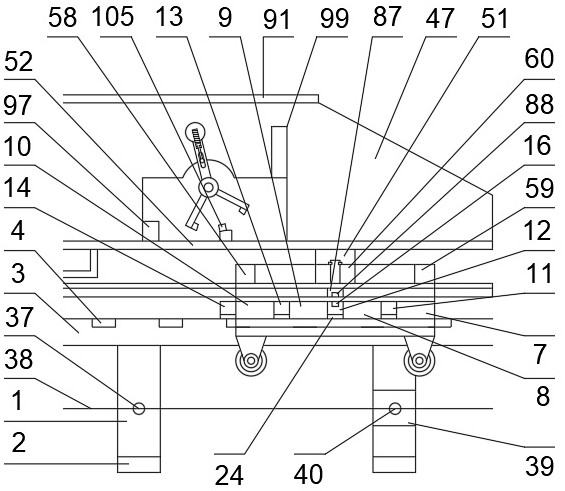

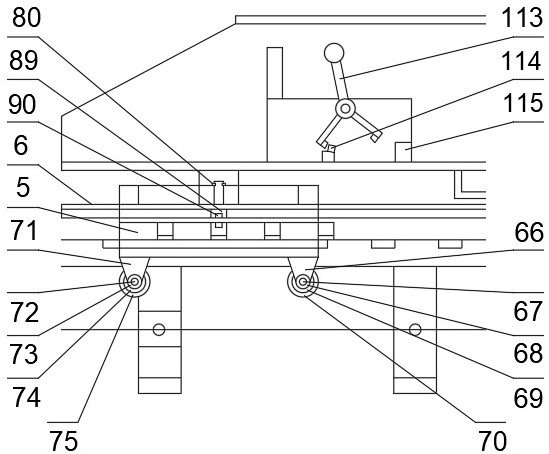

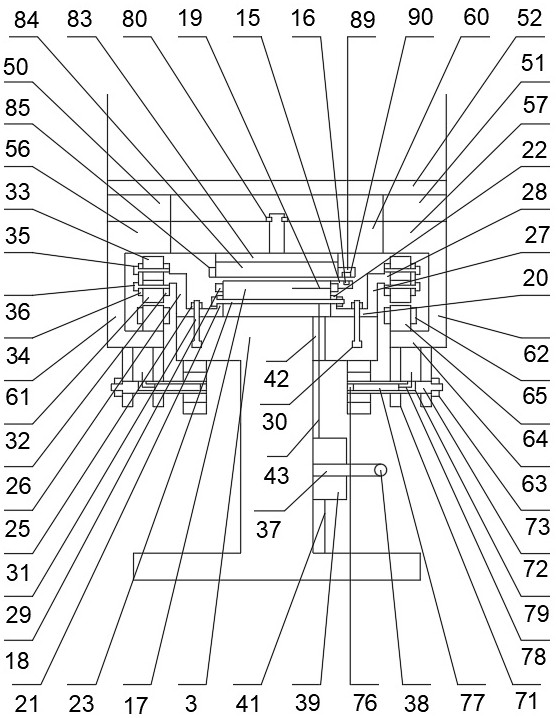

[0012] Further description will be made below in conjunction with accompanying drawings.

[0013]The multi-stator traction high-speed maglev train system adopts the power supply mode of the non-contact power grid, realizes the wireless power supply of the traction system of the high-speed maglev train through the traction mode of multiple linear motor units outside the vehicle, and realizes the maglev through the power supply system of photovoltaic panels and batteries For the wireless power supply of the control system, the multi-stator traction system with less copper and iron is used to replace the long-stator traction system with a large amount of copper and iron, and the supporting pressure difference constant device is used to save the complicated electromagnetic control system; the multi-stator traction high-speed maglev train The system is equipped with an elevated passage, which is a high-speed passage with independent right of way enjoyed by high-speed maglev trains. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com