Hot spot fault detection method for photovoltaic cell panel

A photovoltaic panel and fault detection technology, applied in photovoltaic power generation, photovoltaic system monitoring, photovoltaic modules, etc., can solve problems such as few hot spot fault diagnosis methods, lack of self-learning ability of fuzzy reasoning, cumbersome manual data collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

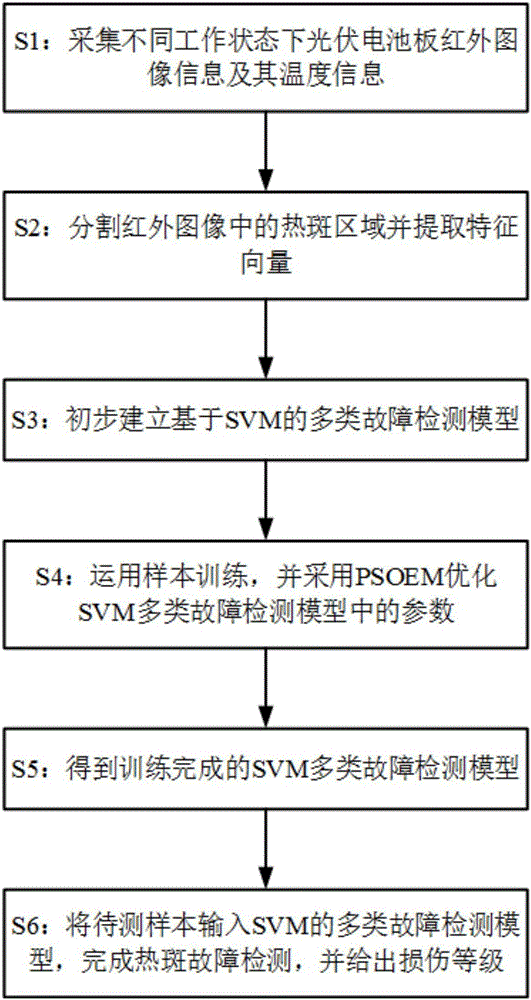

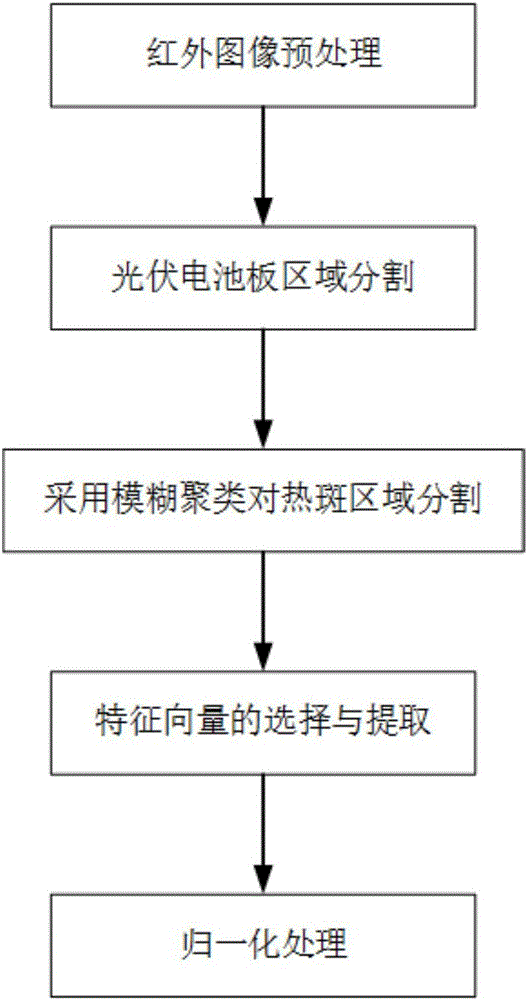

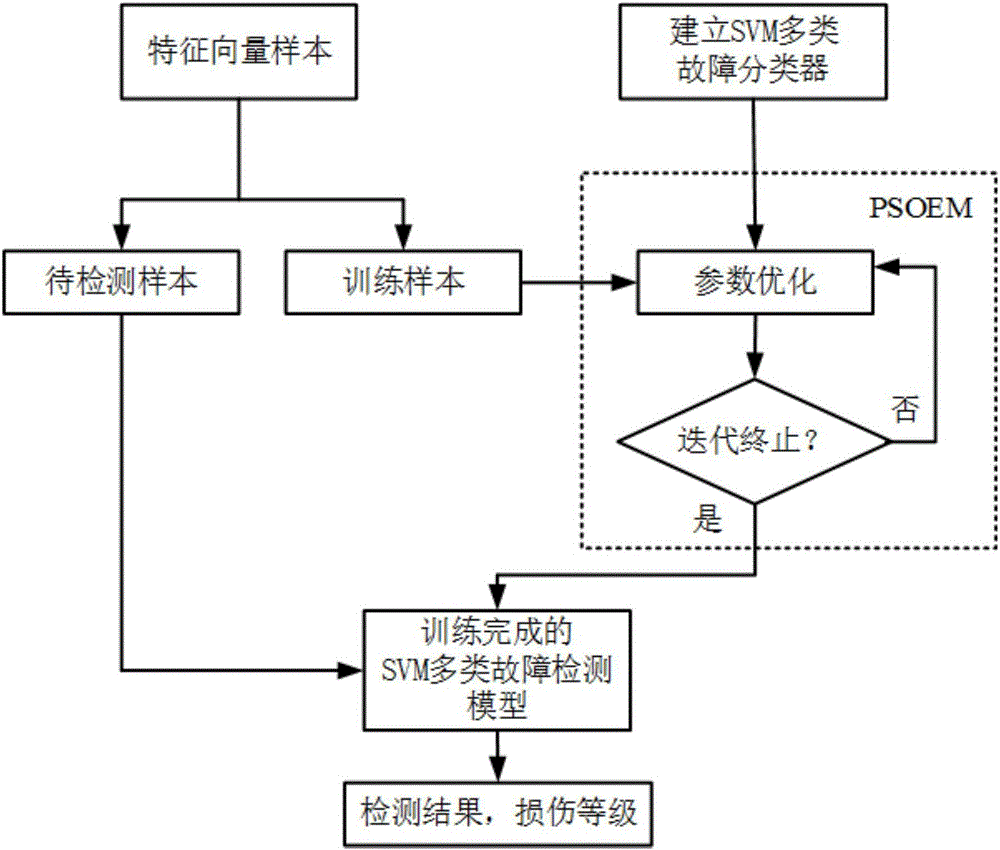

[0066] figure 1 It is a flow chart of a photovoltaic panel hot spot fault detection method, figure 2 A flow chart for infrared image feature vector extraction, image 3 Build a flowchart for the SVM multi-class fault detection model, Figure 4 For the PSOEM parameter optimization flow chart, as shown in the figure: a kind of photovoltaic panel hot spot fault detection method provided by the present invention comprises the following steps:

[0067] S1: Collect infrared image information and temperature information of photovoltaic panels under normal and different hot spot fault states;

[0068] S2: Segment the hot spot area in the infrared image and extract the feature vector;

[0069] S3: Initially establish a multi-type fault detection model based on SVM;

[0070] S4: Use the training samples to train the SVM multi-class fault detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com