Disc type magnetism increasing DC generator

A technology of DC generators and generators, applied in the direction of generators/motors, AC/DC converters, synchronous motors with stationary armatures and rotating magnets, etc., which can solve the problems of inconvenient use, environmental pollution, and lack of pure magnetic energy DC generator and other problems, to achieve the effect of easy maintenance and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

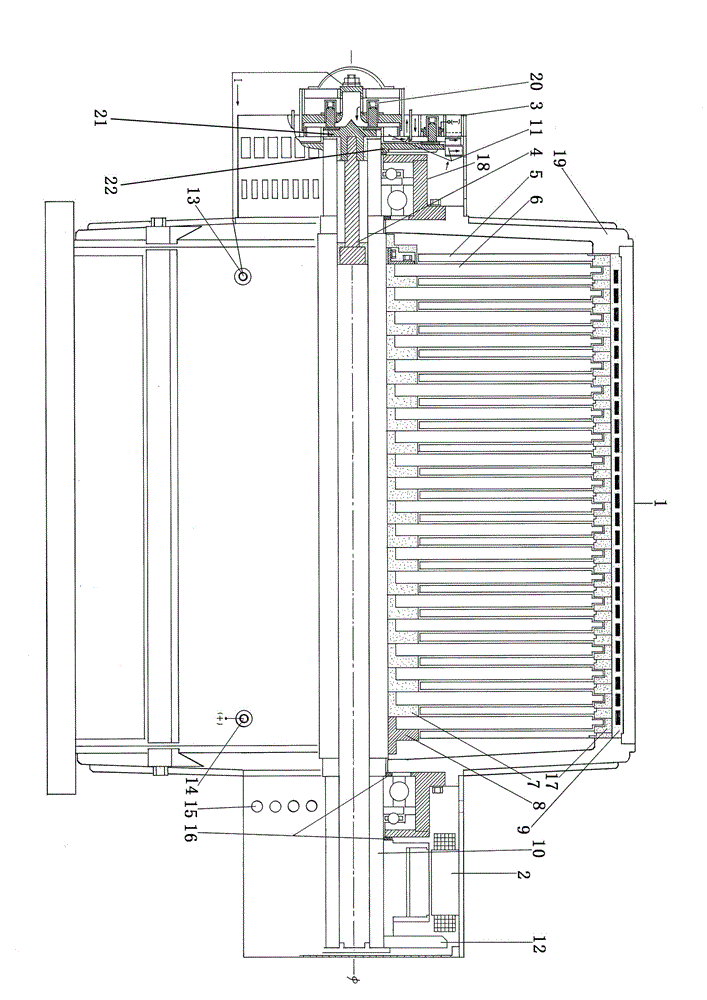

[0025] Such as figure 1 Shown, (horizontal) disk magnetized DC generator. It consists of three parts, 1 1. DC generator; Stator; By permanent magnetic disc 5 and structural ceramic insulating washer 17, spaced layer by layer with generator disc 6, constituting fixed permanent magnet magnetic source in casing coil 9. [ Case Coil ( Magnetic coil ) , made of aluminum strip or copper strip ( Wire ) It is wound into a coil matching the casing, and cast into the casing with insulating structural ceramics ] . rotor ; by the generator plate, ( Generating plate: It is composed of aluminum alloy generating plate, connected with copper alloy conductive ring, conductive ring connected with structural ceramic insulated bus bar, insulated bus bar is provided with positive connecting terminal, aluminum alloy generating plate is provided with negative connecting terminal ) And structural ceramics insulating electric disk seat 7, with permanent magnetic disk layer by layer interval, ...

Embodiment 2

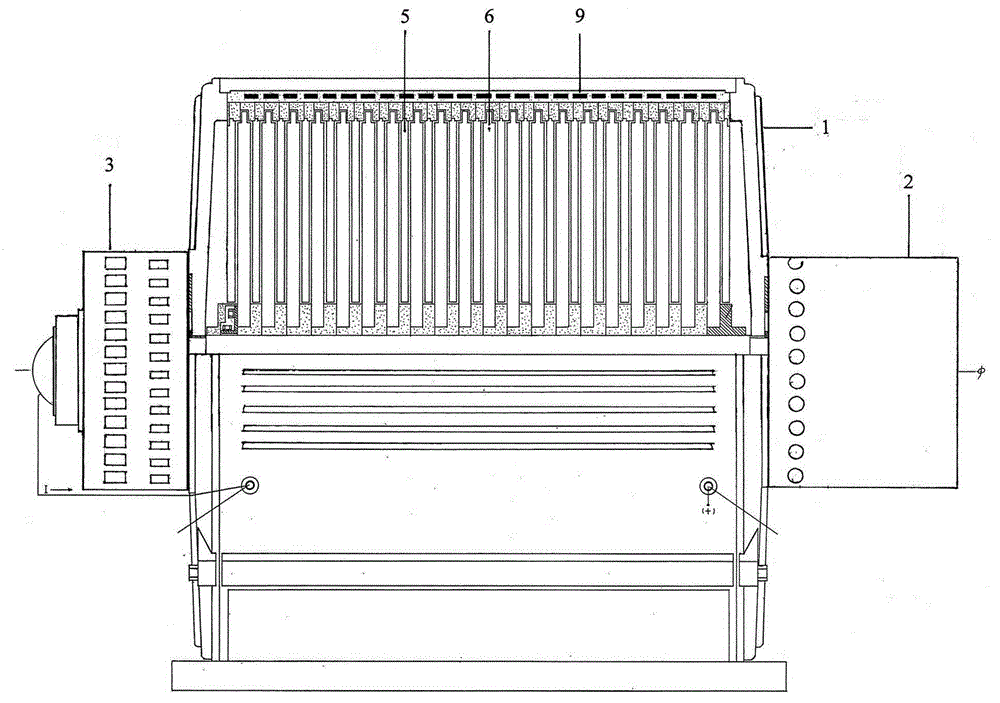

[0031] Such as Figure 5 shown ,( Vertical and horizontal dual-purpose) disc-type magnetized DC generator, which is shown in the figure 1 On the basis of the horizontal disc magnetized DC generator, it is changed to form ( Vertical and horizontal) disc-type magnetized DC generator. with diagram 1 There are different places for horizontal DC generators, DC generators 7 Install the vertical frame on the negative side 10 . drag motor 4 Installed on the positive side of the DC generator. (The drive motor is a split structure) The rotor is installed on the shaft of the DC generator, and the stator is fixed on the end cover of the generator. Disc Brush Conductive Output Device 1 Installed on the extended part of the drag motor casing. ( DC generator shaft lengthened accordingly ), The positive conductive plate is connected to the conductive terminal in the shaft , The negative conductive disc is connected to the shaft 。 The bottom end cover is thickened so that the load...

Embodiment 3

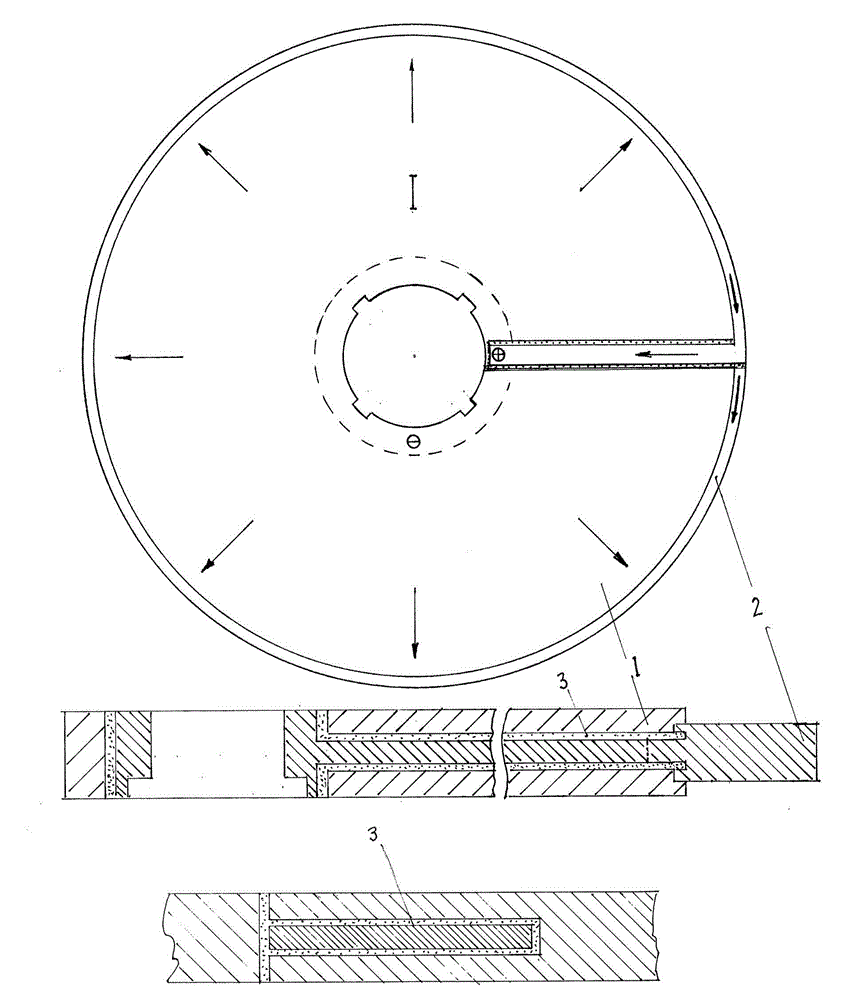

[0033] Such as Figure 6 shown ,( vertical) disc magnetized DC generator, is in Fig. 5 (stand Horizontal and dual-purpose) based on the disc-type magnetized DC generator, after removing the horizontal frame. Constitute a (vertical) disk-type magnetized DC generator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com