Intelligent burning-preventive electronic deinsectization lamp control circuit

A technology for controlling circuits and insect-killing lamps, which is applied to electrical components, equipment that produces electric shocks, etc., can solve problems such as long-term uninterrupted discharge, unstable circuit current and voltage, chip or circuit burnout, etc., and achieve good results. Intelligent anti-burning effect and fast adjustment ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

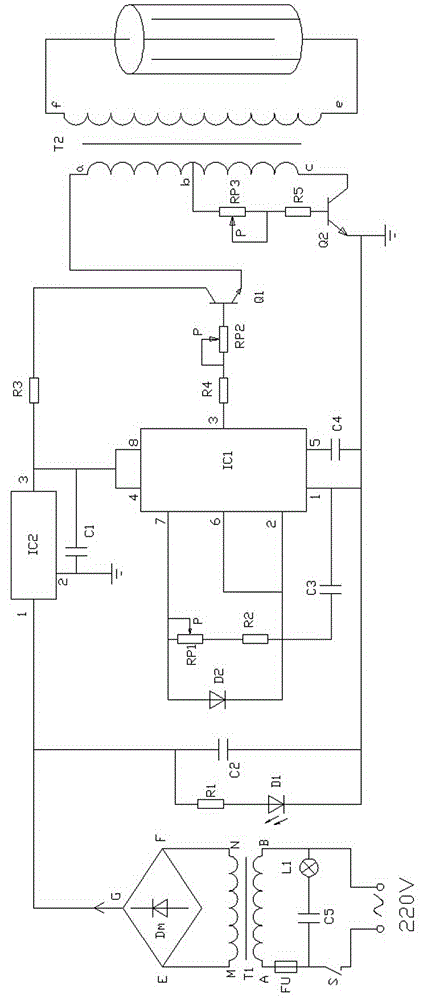

[0020] For ease of explanation, below in conjunction with accompanying drawing, the control circuit of the intelligent anti-burning electronic pest control lamp of the patent application is described in detail.

[0021] like figure 1 As shown in , an intelligent anti-burning electronic pest control circuit includes a rectification module, a boost module and a regulation control module. An adjustment control module is connected to the output terminal of the diode Dm, and the adjustment control module includes a three-terminal voltage stabilizing integrated chip IC2 and a time base integrated chip IC1.

[0022] The power supply is a 220V AC power supply, the live wire of the power supply is connected to one end of the switch S, the other end of the switch S is connected to one end of the capacitor C5, the other end of the capacitor C5 is connected to one end of the indicator light L1, and the other end of the indicator light L1 One end is connected to the neutral wire of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com