Full-automatic peeling and discharging device for capsule-type box and capsule-type box used by device

A technology of a discharging device and a capsule box, which is applied in the field of food processing, and can solve problems such as difficult peeling of the capping skin, difficult machine peeling, waste of coffee powder, etc., to achieve simple peeling, avoid waste, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

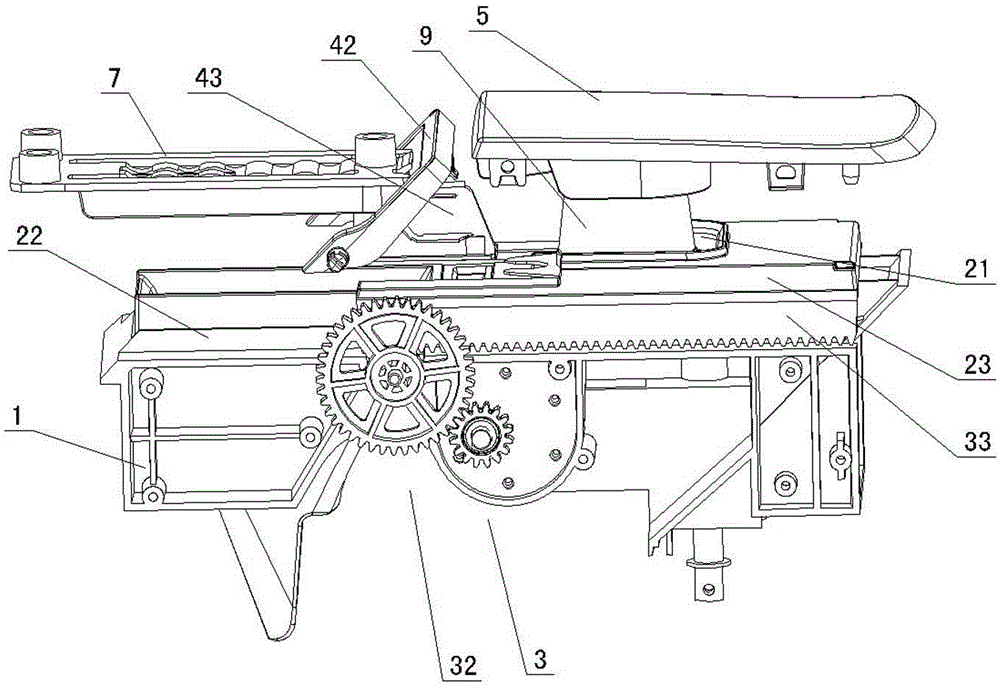

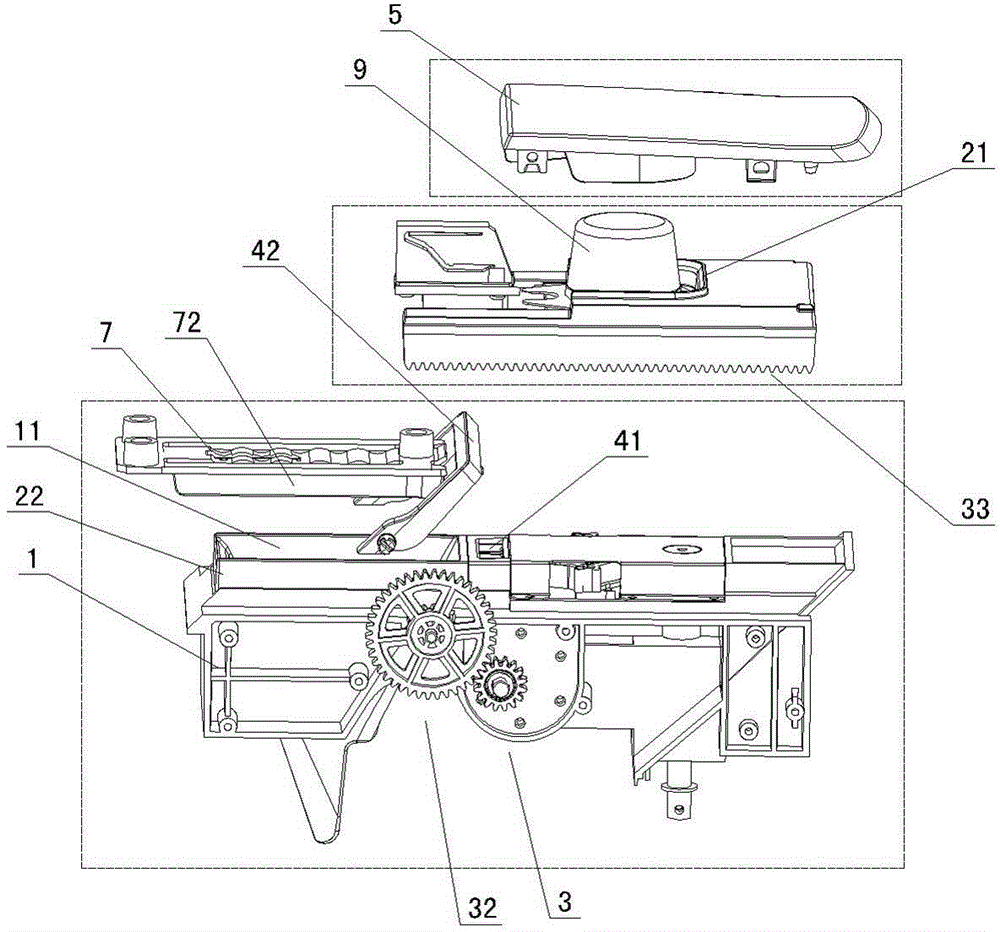

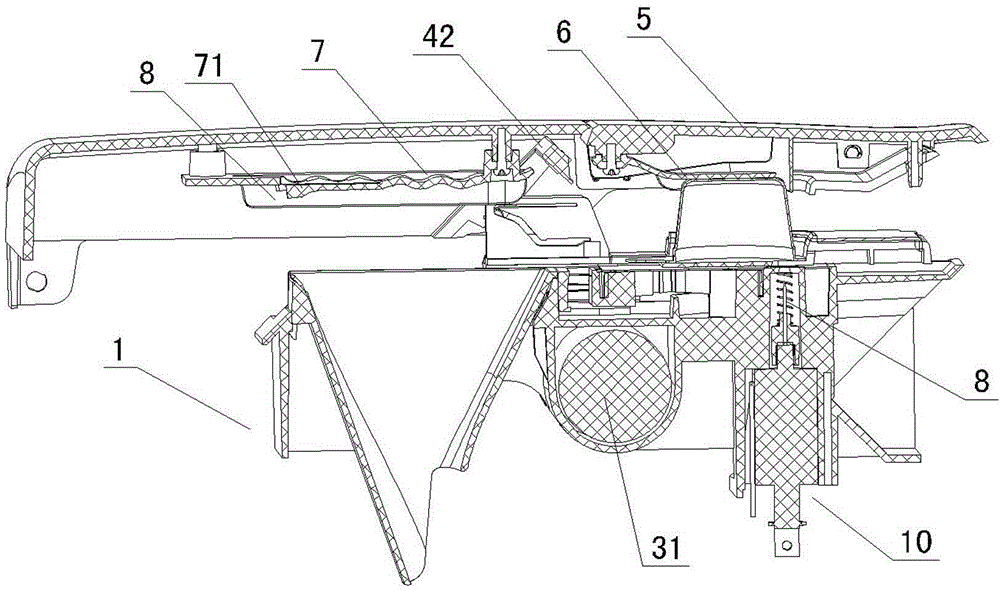

[0022] Such as Figure 1-Figure 4 As shown, the fully automatic capsule box peeling and discharging device (also called peeling and discharging device) of the present invention includes a base 1, a bracket assembly 2 installed on the base 1, a driving assembly 3 and a sealing wallet Tightening mechanism 4, described base 1 is provided with material inlet 11, and the top of described bracket assembly 2 or base 1 is provided with the auxiliary dynamic discharge assembly (preferably scheme is set Above the bracket assembly 2), the driving assembly 3 drives the bracket assembly 2 and the sealing leather to clamp after the sealing leather clamping mechanism 4 clamps the sealing leather of the capsule box on the bracket assembly 2 The relative movement of the mechanism 4 causes the sealing skin to be torn from the capsule box, and all the food in the capsule box falls into the feeding port 11 provided on the base 1 or enters the brewing mechanism under the action of the auxiliary di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com