Drum sieve water chestnut fire peeling device

A trommel sieve and water chestnut technology, which is applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of excessive loss, large damage of water chestnuts, and affecting the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

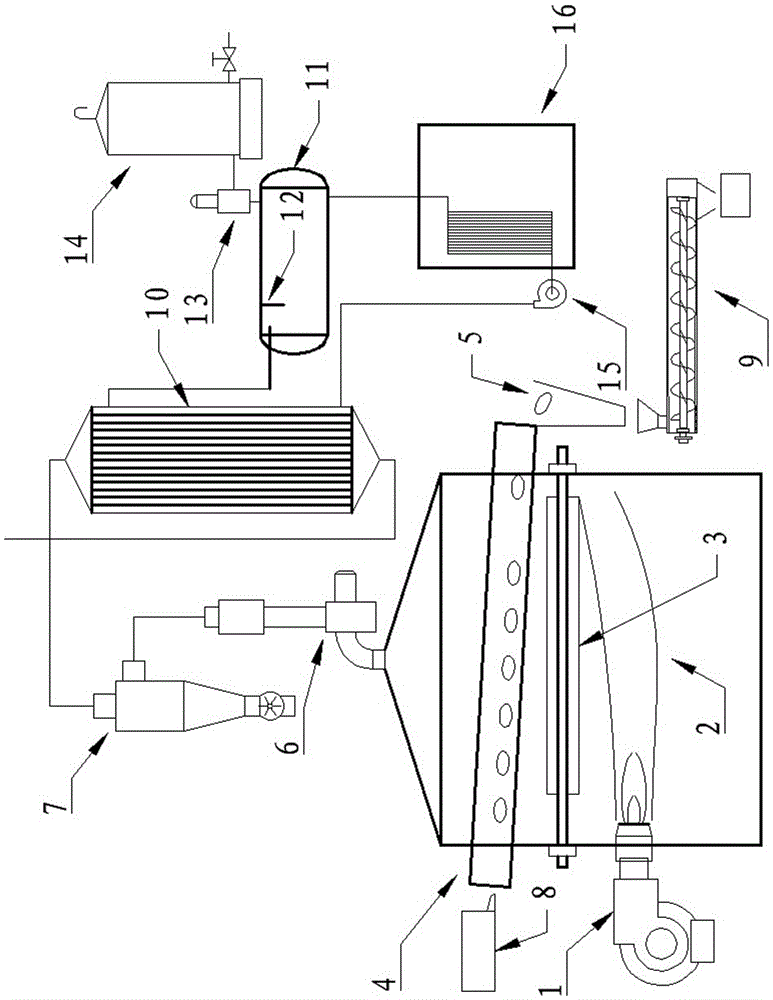

[0023] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0024] like figure 1 and figure 2 The shown trommel type water chestnut peeling device by fire method comprises a trommel 4 and a burner 1, a long paddle flame agitator 3 is arranged between the trommel 4 and the flame of the burner 1, the trommel 4, the long paddle The flame stirrer 3 and the burner 1 constitute the firing and carbonization part. The trommel 4 can adjust the inclination angle and rotating speed. There is a thick enough heat insulation layer in the outer enclosure to form a barbecue chamber; the trommel 4 is provided with a gas collecting hood , the gas collection hood is connected to the cyclone dust collector 7 through the exhaust fan 6, and the cyclone dust collector 7 is connected to the tube side of the tube-and-tube heat exchanger 10 and then emptied. The heat exchanger in 16 and the buffer tank 11 form a loop; the feed end of the trommel 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com