Preparation method of magnetic hydroxyl stearate oil gelling agent

A technology of hydroxystearate and gelling agent, applied in the field of petrochemical industry, can solve the problem of high preparation cost, and achieve the effects of reducing production cost, high strength and thorough treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiment of the present application provides a method for preparing a magnetic hydroxystearate oil gelling agent, which solves the technical problem of high preparation cost in the prior art when using stearic acid to prepare a hydroxystearate oil gelling agent .

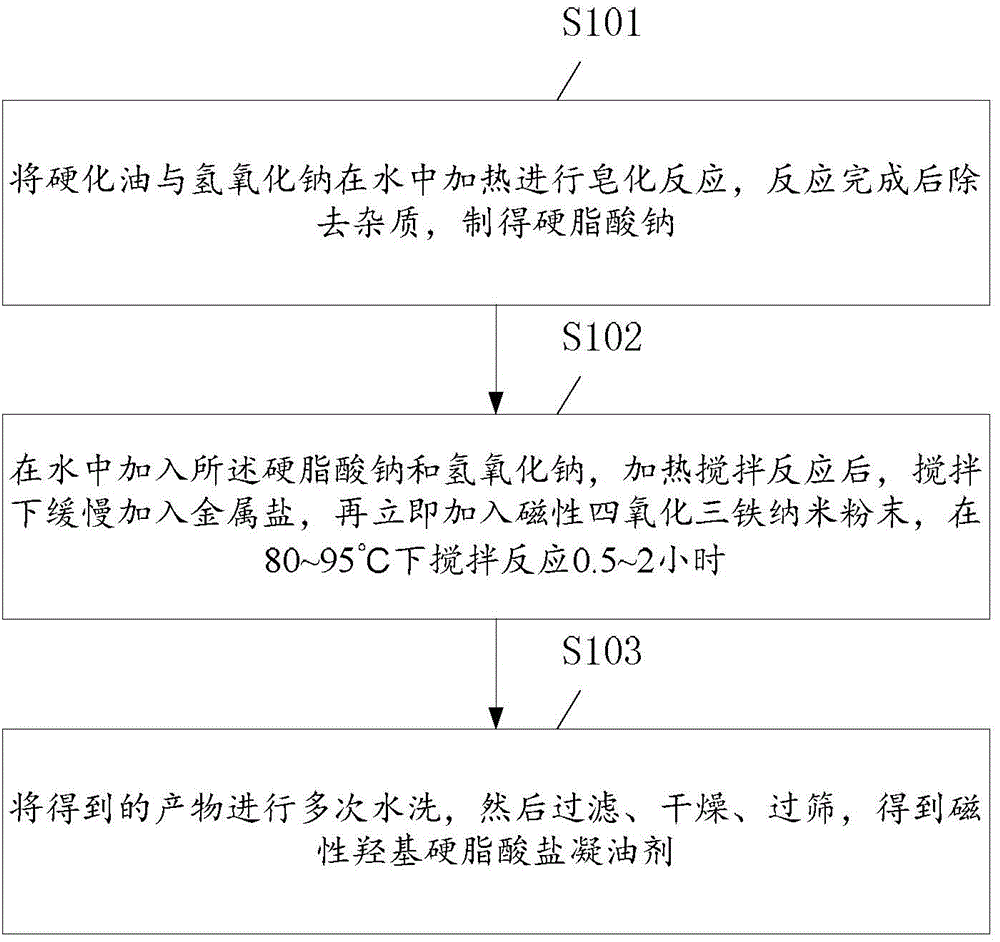

[0046] The embodiment of the present application provides a preparation method of a magnetic hydroxystearate oil gelling agent, such as figure 1 shown, including:

[0047] Step S101: heating the hardened oil and sodium hydroxide in water for saponification reaction, and removing impurities after the reaction is completed to obtain sodium stearate;

[0048] Step S102: Add the sodium stearate and sodium hydroxide into the water, heat and stir to react, slowly add the metal salt under stirring, then immediately add the magnetic Fe3O4 nanopowder, stir and react at 80-95°C for 0.5- 2 hours;

[0049] Step S103: The obtained product is washed with water several times, then filtered, dried, and sieved to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com