Method for utilizing infrared thermal imaging technology to detect floor heating pipe

A technology of infrared thermal imaging and infrared thermal imaging camera, which is used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. Detecting the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

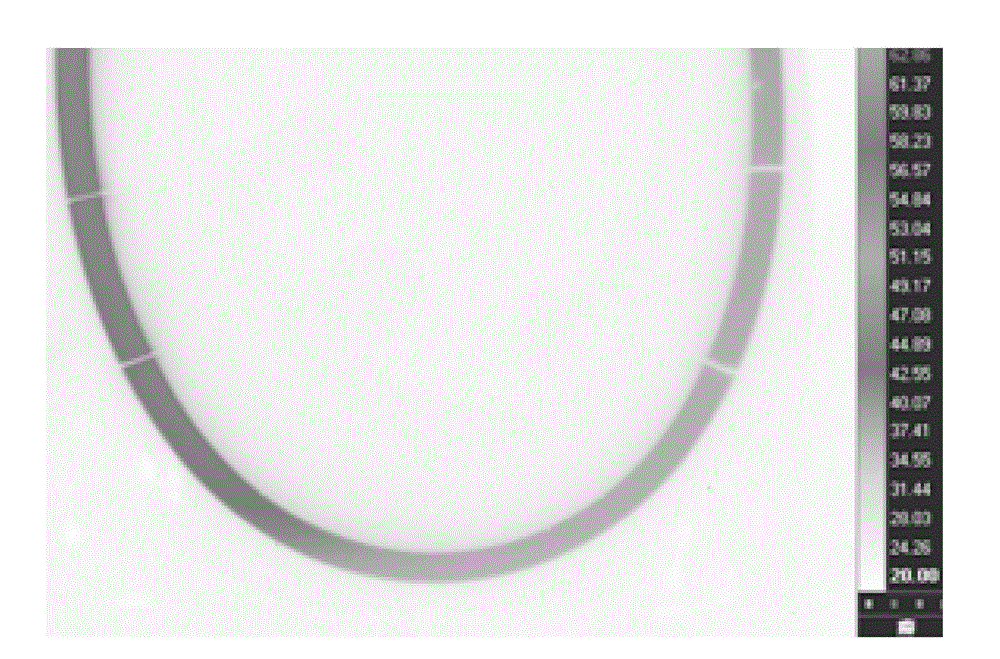

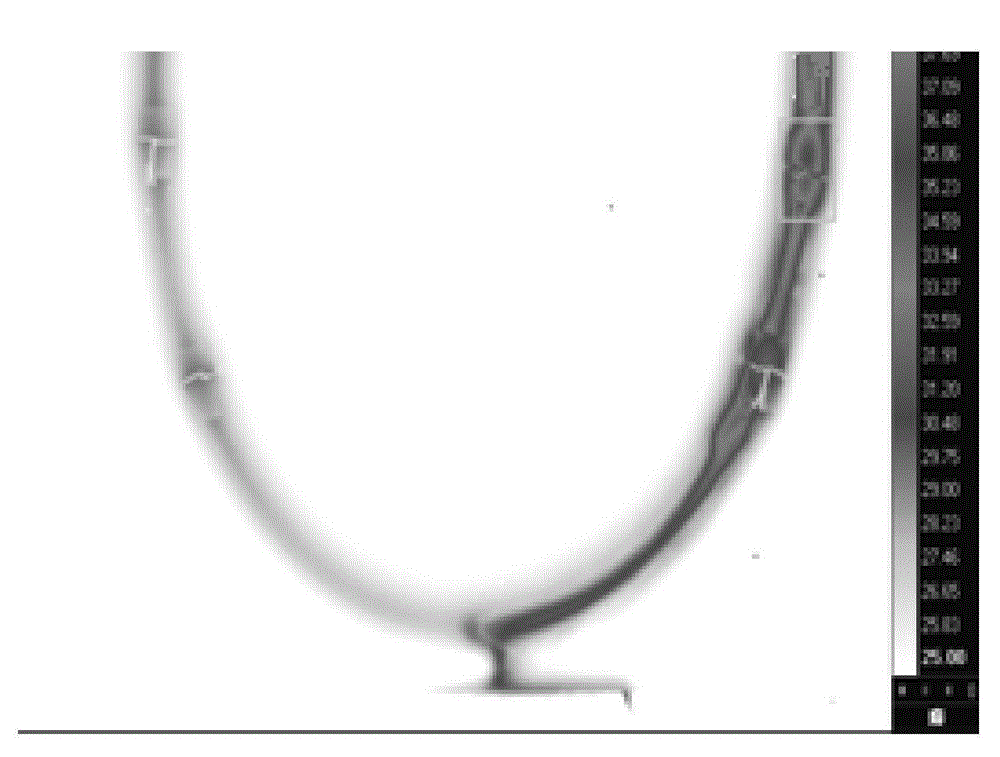

[0023] Turn on the SC7000 infrared thermal imager and perform preheating treatment: place it for 15 minutes until the sound of the internal pump becomes smaller until it disappears and the image is stable, and it is connected to the computer; open the floor heating valve, adjust the pipeline test parameters, and control the water temperature to 50℃, water velocity is 0.05m 3 / h, make hot water flow into the floor heating pipe and preheat for 4 hours, place the infrared thermal imaging camera in a corner of the room, use the infrared thermal imaging camera supporting software FLIR Altair to calibrate the room coordinates, and record the video at the angle of the lens perpendicular to the floor, The distance between the lens and the floor is 30cm, and it moves along the floor plane in a row scanning manner until it moves to the opposite side of the room to save the video content. Use the supporting software of the infrared thermal imager to synthesize the pipeline layout diagram...

Embodiment 2

[0025] Turn on the SC7000 infrared thermal imager and perform preheating treatment: place it for 17 minutes until the sound of the internal pump becomes smaller until it disappears and the image is stable, and it is connected to the computer; open the floor heating valve, adjust the pipeline test parameters, and control the water temperature to 55℃, water velocity is 0.07m 3 / h, make hot water flow into the floor heating pipe and preheat for 4.5 hours, place the infrared thermal imaging camera in a corner of the room, use the infrared thermal imaging camera supporting software FLIR Altair to calibrate the room coordinates, and record the video at the angle of the lens perpendicular to the floor, The distance between the lens and the floor is 40cm, and it moves along the floor plane in a row scanning manner until it moves to the opposite side of the room to save the video content. Use the supporting software of the infrared thermal imager to synthesize the pipeline layout diagr...

Embodiment 3

[0027] Turn on the SC7000 infrared thermal imager and perform preheating treatment: place it for 20 minutes until the sound of the internal pump becomes smaller until it disappears and the image is stable, and it is connected to the computer; open the floor heating valve, adjust the pipeline test parameters, and control the water temperature to 60℃, water velocity is 0.1m 3 / h, make hot water flow into the floor heating pipe and preheat for 5 hours, place the infrared thermal imaging camera in a corner of the room, use the infrared thermal imaging camera supporting software FLIR Altair to calibrate the room coordinates, and record the video at the angle of the lens perpendicular to the floor, The distance between the lens and the floor is 50cm, and it moves along the floor plane in a row scanning manner until it moves to the opposite side of the room to save the video content. Use the supporting software of the infrared thermal imager to synthesize the pipeline layout diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com