Industrial kiln door, manufacturing method thereof and used cast material

A technology of casting materials and manufacturing methods, which is applied in the field of casting materials and industrial kiln doors, can solve the problems of materials, manpower waste, poor thermal insulation performance of furnace doors, inconvenient maintenance, etc., to prevent product cracking, low cost, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

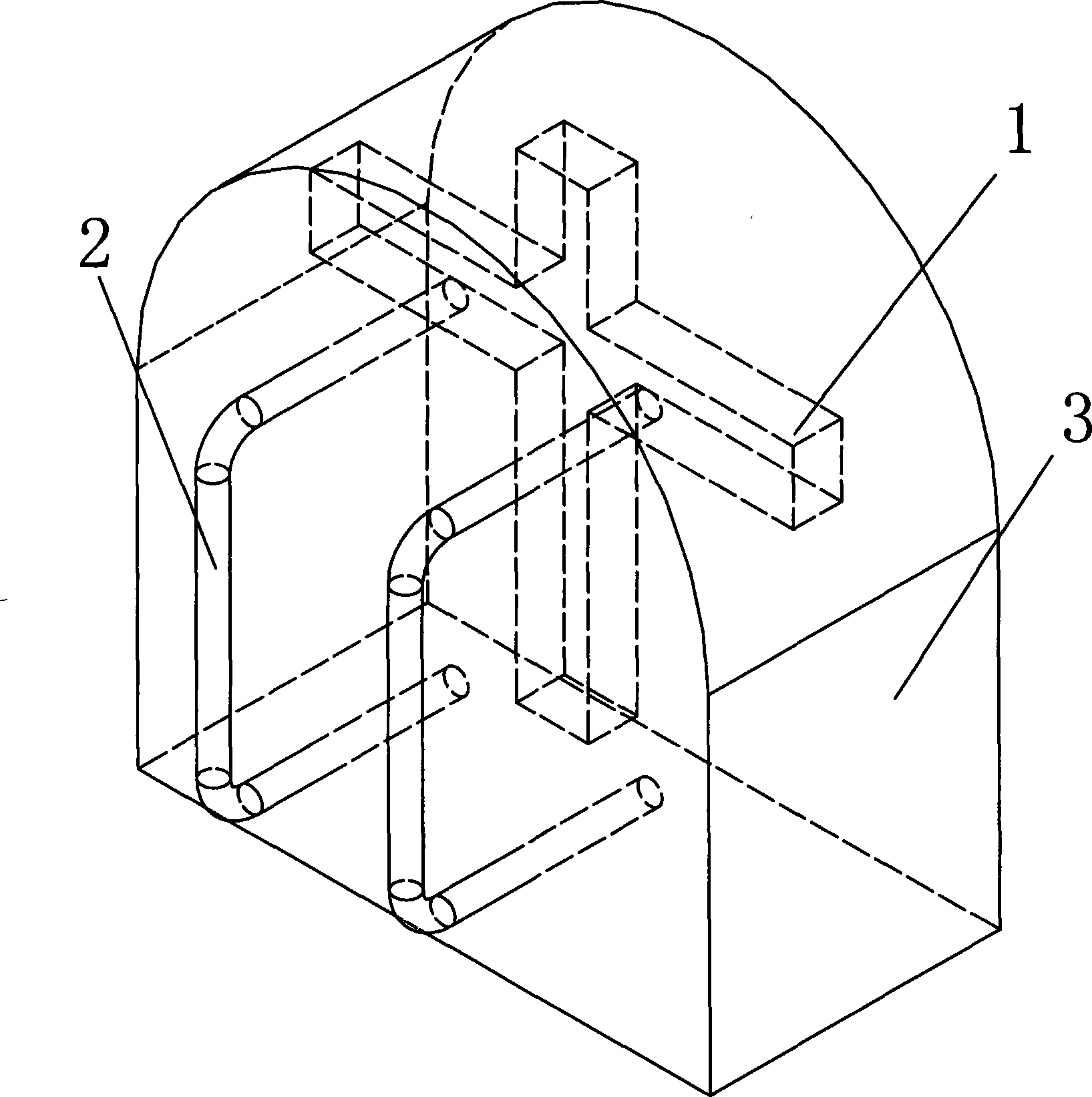

[0026] like figure 1 As shown, the industrial kiln door of the present invention has a handle 2 welded on the cross frame 1, the body 3 is wrapped outside the frame 1, and the body 3 is made of heat-resistant and heat-insulating material poured on the frame 1.

Embodiment 2

[0028] The manufacturing method of the industrial kiln furnace door described in Example 1: first, the temperature-resistant and heat-insulating pouring material containing 4kg polycrystalline mullite fiber, 3kg zirconium-containing fiber and 2.5kg high-alumina fiber is mixed with 0.5kg of binder , crushed to 180 mesh with a mixer; put the pre-made skeleton into the mold, pour the mixed material on the skeleton in the mold to get the blank, squeeze the blank with a hydraulic press, and squeeze out the moisture in the blank; put the formed The blanks are dried in the sun for 4 days; the dried blanks are baked in an oven at 300°C for 24 hours; the baked blanks are calcined in an electric kiln at 1200°C for 48 hours; the calcined blanks are according to the actual industrial kiln door In some cases, use an electric saw to process the shape and size of the furnace door to a suitable size, and finally smooth it with sandpaper to obtain the desired furnace door.

[0029] Wherein the...

Embodiment 3

[0033] Identical to the structure of the industrial kiln furnace door of Example 1, its manufacturing method is as follows: first, the temperature-resistant and heat-resisting pouring material containing 4.5kg polycrystalline mullite fiber, 2.5kg zirconium-containing fiber and 2.3kg high-alumina fiber and 0.7kg Mix the binder and crush it to 180 mesh with a mixer; put the pre-made skeleton into the mold, pour the mixed material on the skeleton in the mold to get the blank, squeeze the blank with a hydraulic press, and squeeze out the dry matter in the blank moisture; air-dry the molded blank in a wind room at 70°C for 6 days; bake the dried blank in an oven at 450°C for 24 hours; place the baked blank in an electric kiln at 1150°C for 48 hours; calcined According to the needs of the actual industrial kiln door, the blank is processed to a suitable shape and size, and polished smooth with sandpaper to obtain the required industrial kiln door.

[0034] Wherein the skeleton and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com