Nested ring mems vibrating gyroscope with variable resonant ring wall thickness

A technology of vibrating gyroscope and resonant ring is applied in the direction of speed measurement, gyroscope/steering sensing device, measuring device, etc. with gyro effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

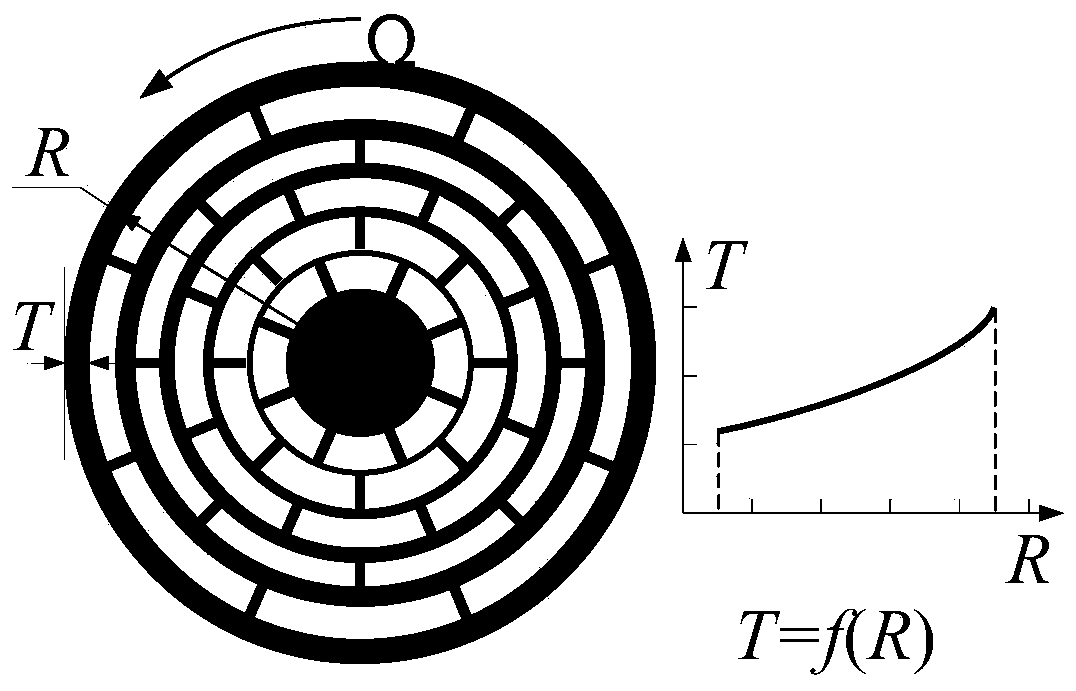

[0027] The feature of the present invention is that the wall thicknesses of the same resonant ring are equal, and all nested rings have different wall thicknesses from the inside to the outside, and the resonator with variable wall thickness distribution can realize the optimization of quality and stiffness distribution, which helps to improve the performance of the gyroscope. One of the embodiments is that the wall thickness distribution function of the nested resonant ring decreases linearly from the inside to the outside, and its structure is as follows Figure 4 shown. The resonator 10 with variable wall thickness distribution includes a resonator ring 11, a spoke-shaped support beam 12, and an anchor point 13 located at the center of the resonator structure. The entire resonator is firmly anchored to the substrate through the anchor point 13 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com