A Method for Predicting the Calendar Life of Aging Aircraft Metal Structures

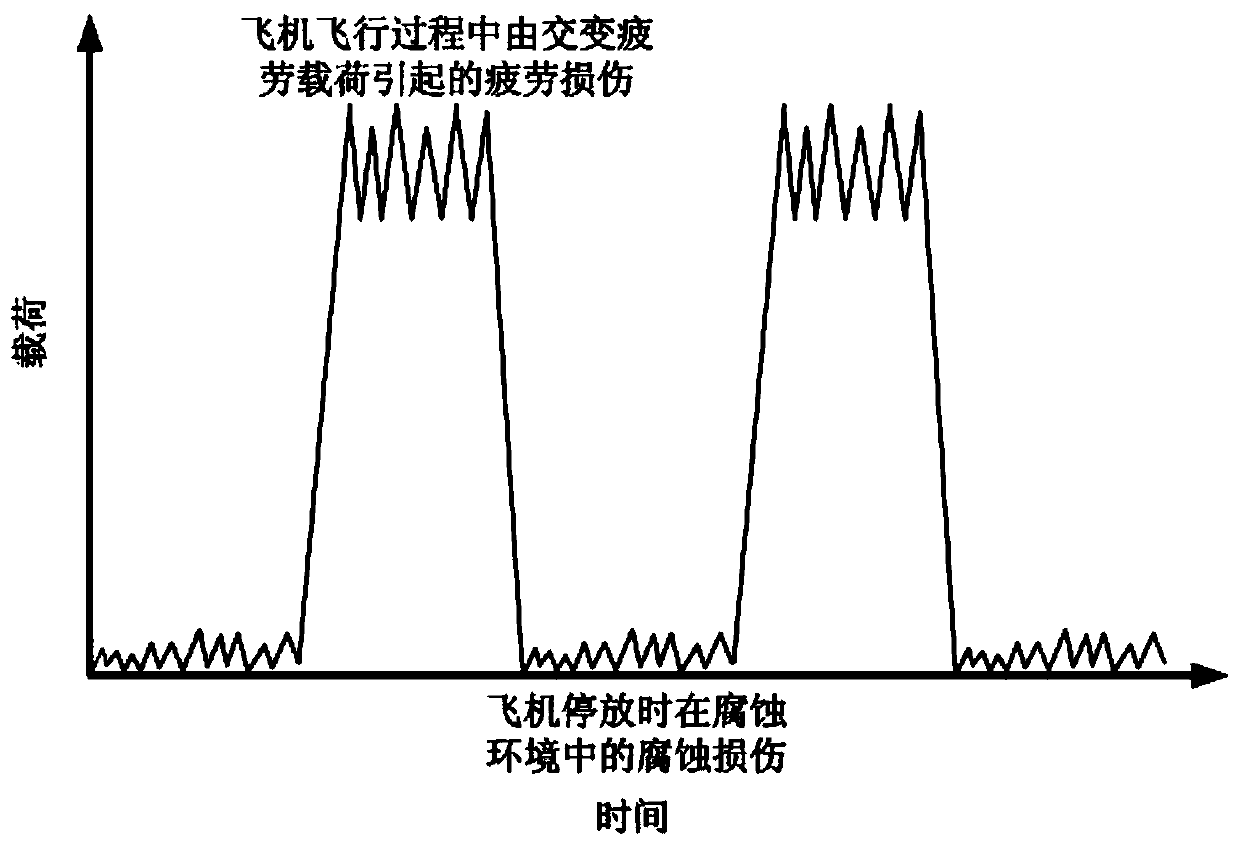

A metal structure, calendar technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low flight intensity, neglect of pit interaction, erosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

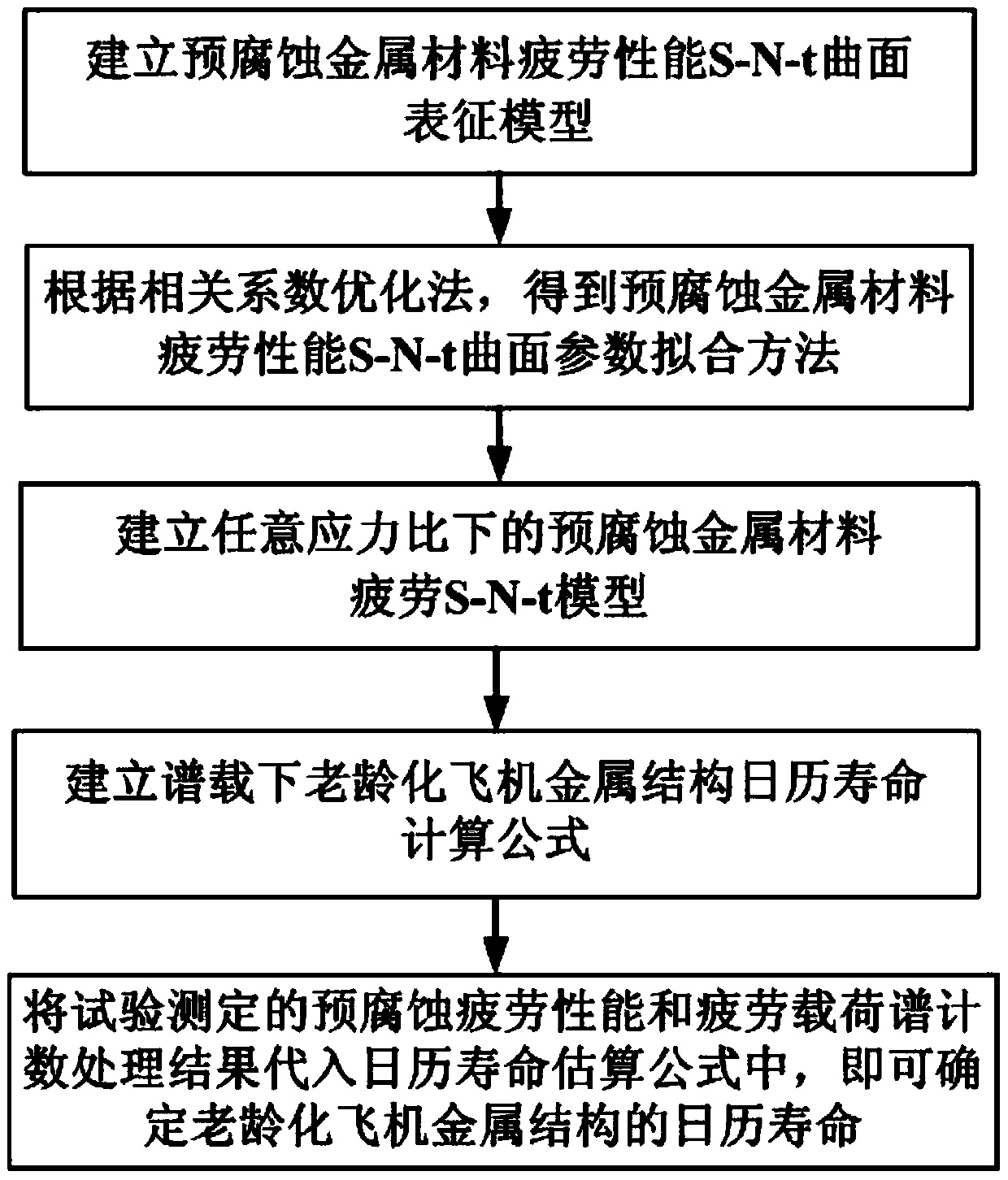

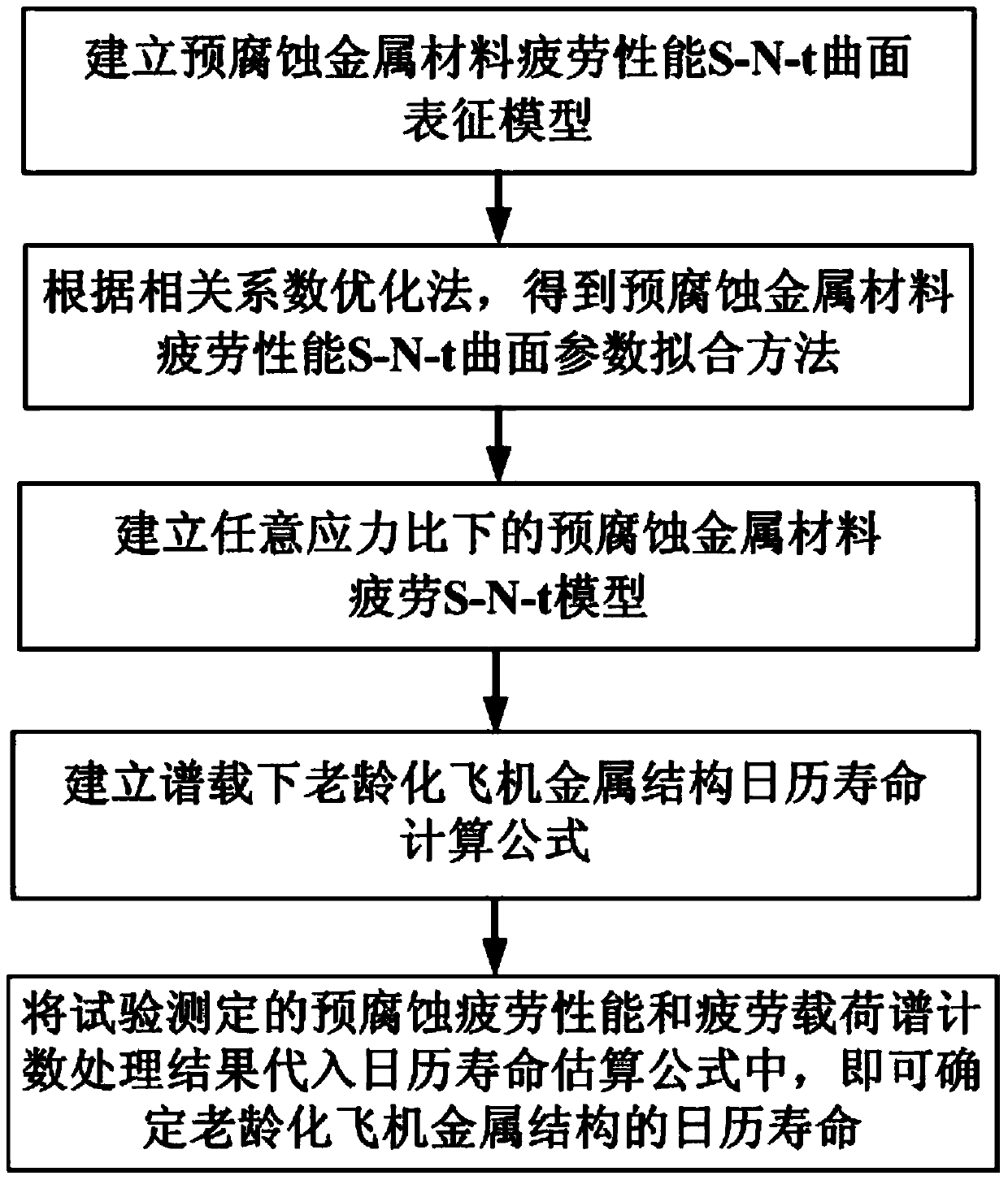

[0075] figure 2 It is the block flow chart of method for the present invention, and the present invention is realized in five steps, specifically:

[0076] Step 1. S-N-t surface characterization model of fatigue performance of pre-corroded metal materials

[0077] The fatigue performance of materials or structures is usually characterized by a three-parameter power function expression under a specified stress ratio. Therefore, the specified stress ratio R 0 Under the following conditions, the fatigue performance of materials or structures corresponding to different calendar corrosion years (that is, the S-N curve) can be written as

[0078]

[0079] In the formula, Indicates the specified stress ratio R 0 The maximum stress that the material can bear when the lower life is N; S 0 (t) is the fitted fatigue limit under different calendar years; m and C represent the shape parameters of the fatigue curve; N represents the fatigue life.

[0080] Obviously, the specified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com