Passive high-voltage direct-current circuit breaker and implementation method therefor

A high-voltage direct current and circuit breaker technology, applied in high-voltage/high-current switches, circuits, circuit devices, etc., can solve the problems that the breaking time cannot meet the requirements of multi-terminal flexible direct current transmission systems, high manufacturing costs, and high technical difficulty, so as to shorten the operation The effect of time, low equipment cost and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

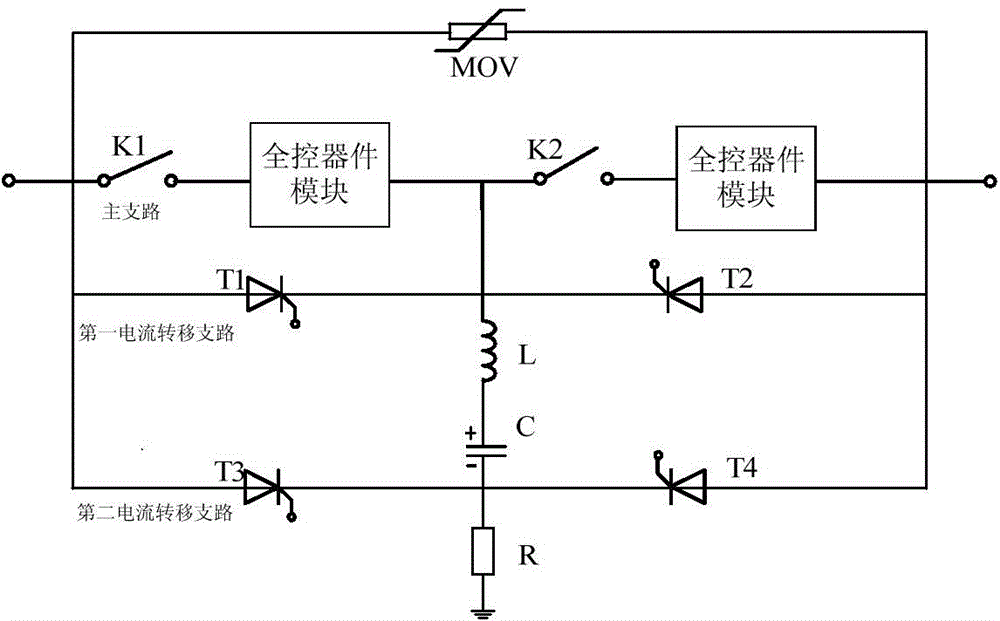

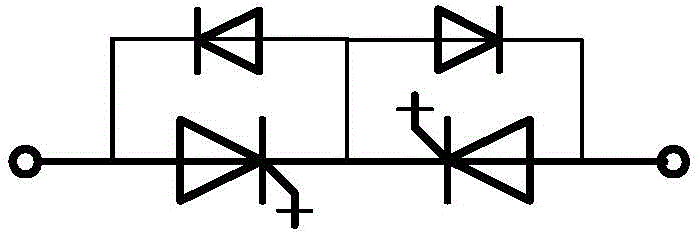

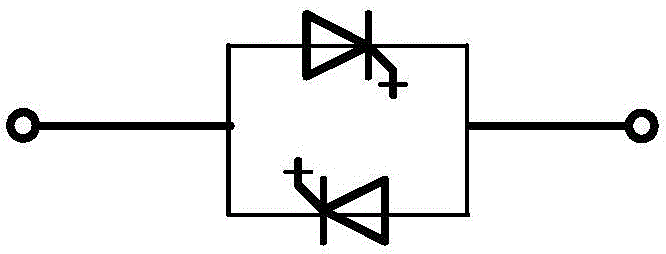

[0045] The topological structure diagram of the passive high-voltage DC circuit breaker provided by the present invention is as follows figure 1 As shown, the high-voltage DC circuit breaker is connected in series to the DC system through ports 1 and 2, including a parallel energy absorption branch, a main branch and a current transfer branch. The current transfer branch includes the first current transfer branch and the first current transfer branch. The second current transfer branch; the energy absorption branch is composed of non-linear resistors; the high-voltage DC circuit breaker is connected in series in the DC system, and the main branch includes at least two sets of high-speed mechanical switches and at least two sets of full control in series device module. Two sets of high-speed mechanical switches are denot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com