Wet dust collector

A technology of wet dust collector and mist eliminator, which is applied in the field of machinery, can solve the problems of limited space at the reloading point, small amount of flue gas to be dusted, and large dust and water vapor content, and achieves good dust removal stability, compact structure, Ease of inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

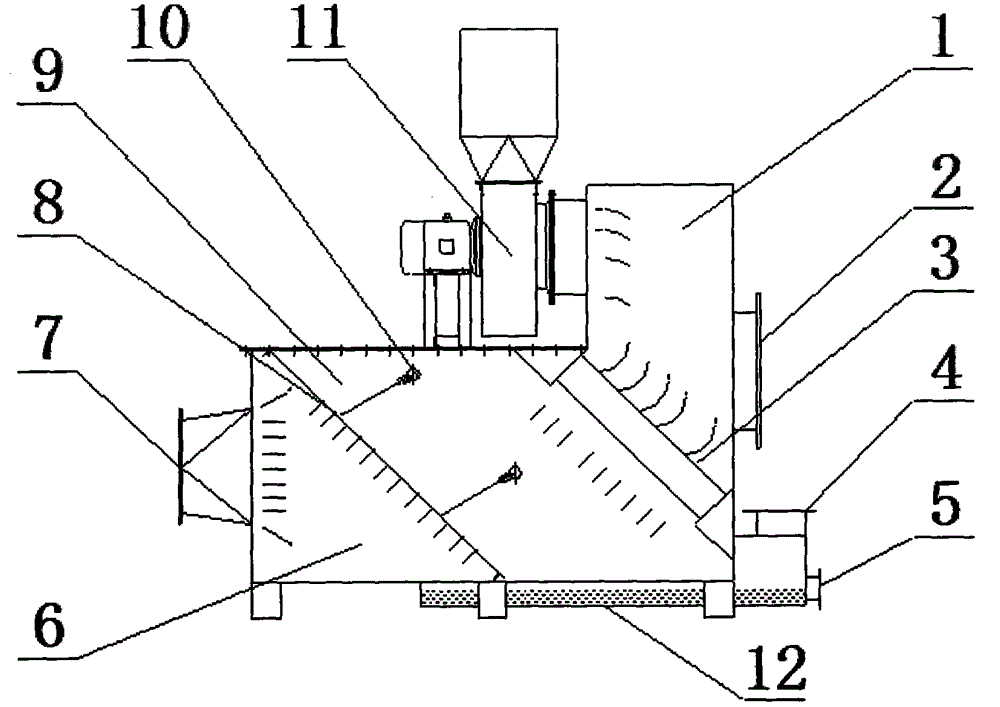

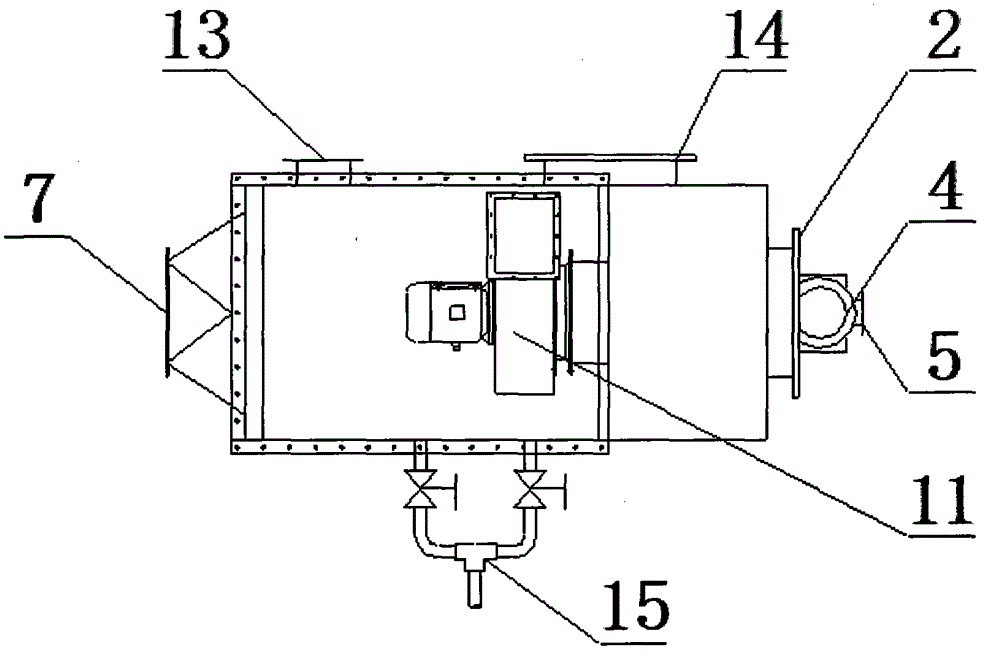

[0020] Such as figure 1 and figure 2 As shown, a wet dust collector includes a housing, a fan 11, a water supply pipe 15, a dehydration demister 3, and a drainage tank 12. It is characterized in that: the housing is provided with a cavity, and the housing There are inlets and outlets connected internally and externally. The outer surface of the housing is provided with a number of inspection holes and manholes. The housing is equipped with a titanium silk curtain mesh plate 8, a spray pipe 10, dehydration and defogging device 3, the titanium wire curtain mesh plate 8 is provided with evenly distributed through holes; the titanium wire curtain mesh plate 8 and the dehydration demister 3 are sequentially arranged in the housing and sequentially divide the inner shell The cavity is three cavities, and the three cavities from left to right are the air inlet chamber 6, the dust removal chamber 9, and the exhaust chamber 1; one side of the air inlet chamber 6 is provided with an a...

Embodiment 2

[0023] Such as figure 1 and figure 2 As shown, a wet dust collector includes a housing, a fan 11, a water supply pipe 15, a dehydration demister 3, and a drainage tank 12. It is characterized in that: the housing is provided with a cavity, and the housing There are inlets and outlets connected internally and externally. The outer surface of the housing is provided with a number of inspection holes and manholes. The housing is equipped with a titanium silk curtain mesh plate 8, a spray pipe 10, dehydration and defogging device 3, the titanium wire curtain mesh plate 8 is provided with evenly distributed through holes; the titanium wire curtain mesh plate 8 and the dehydration demister 3 are sequentially arranged in the housing and sequentially divide the inner shell The cavity is three cavities, and the three cavities from left to right are the air inlet chamber 6, the dust removal chamber 9, and the exhaust chamber 1; one side of the air inlet chamber 6 is provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com