A batch ultrasonic reaction device

A reaction device, ultrasonic technology, applied in the field of intermittent ultrasonic reaction device, can solve the problems of insufficient droplet refinement, low reliability, affecting three-phase reaction and mass transfer efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

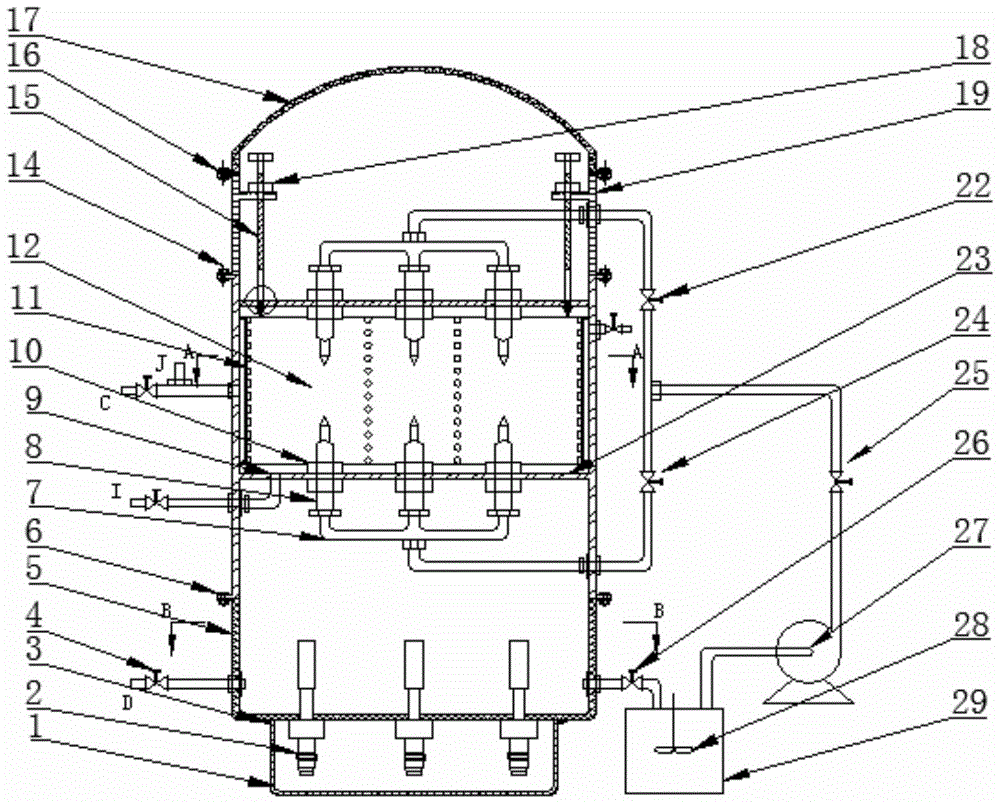

[0022] Such as figure 1 As shown, the present invention is an intermittent ultrasonic reaction device, including a protective cover 1, an ultrasonic acoustic system 2, a screw 3, a first throttle valve 4, an ultrasonic emission tank 5, a first bolt 6, a four-way shunt pipe 7, Pressure nozzle 8, flow guide hole 9, first fastening nut 10, gas-liquid exchange reaction chamber 12, second bolt 14, lead screw 15, third bolt 16, cover 17, second fastening nut 18, support ring 19 , double nuts 21, the second throttle valve 22, the third throttle valve 24, the fourth throttle valve 25, the fifth throttle valve 26, the booster pump 27, the stirring paddle 28 and the circulating liquid storage tank 29.

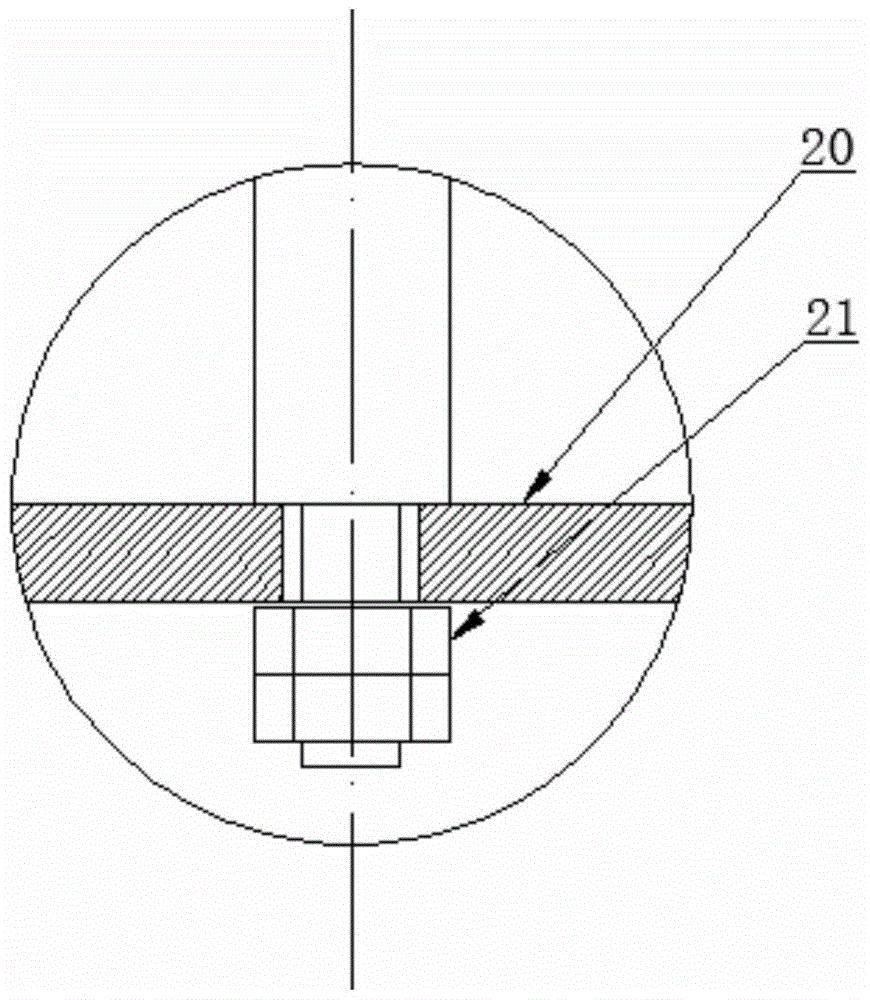

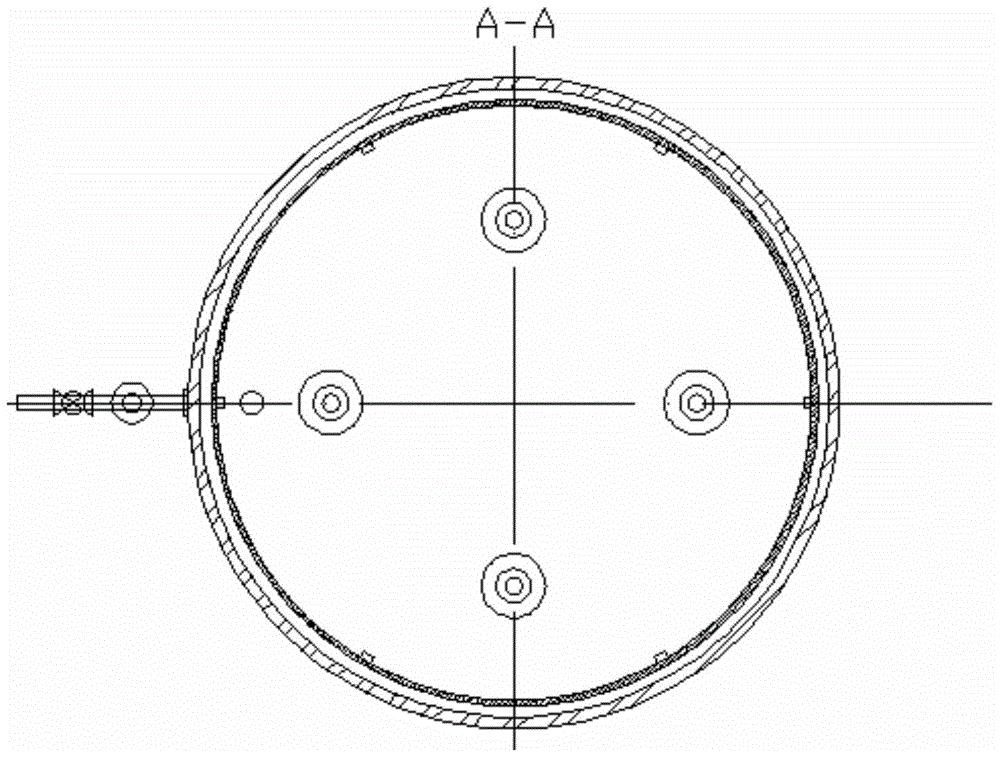

[0023] Such as figure 2 , image 3 , Figure 4 As shown, a 15 kHz ultrasonic acoustic system 2 is arranged at the center of the bottom of the ultrasonic emitting tank 5, and four 20 kHz ultrasonic acoustic systems 2 are symmetrically arranged around it. The protective cover 1 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com