Variable-angle elliptical vibration-laser forming device and method for CBN grinding head preparation

A technology of elliptical vibration and laser forming, which is applied in the coating process of metal materials, coating, etc., can solve the problem that it is difficult to obtain the optimal degree of grain refinement of different metal bonds, and the holding force between abrasive grains and metal bonds is not enough. , The performance of CBN grinding tools has not reached the optimal level, etc., to achieve the effect of improving service life, easy operation, and less difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that all directional indications in the embodiments of the present invention are only used to explain the relative positional relationship and movement conditions between the components in a specific posture in the drawings, and when the specific posture changes, the directional indications are also corresponding change accordingly.

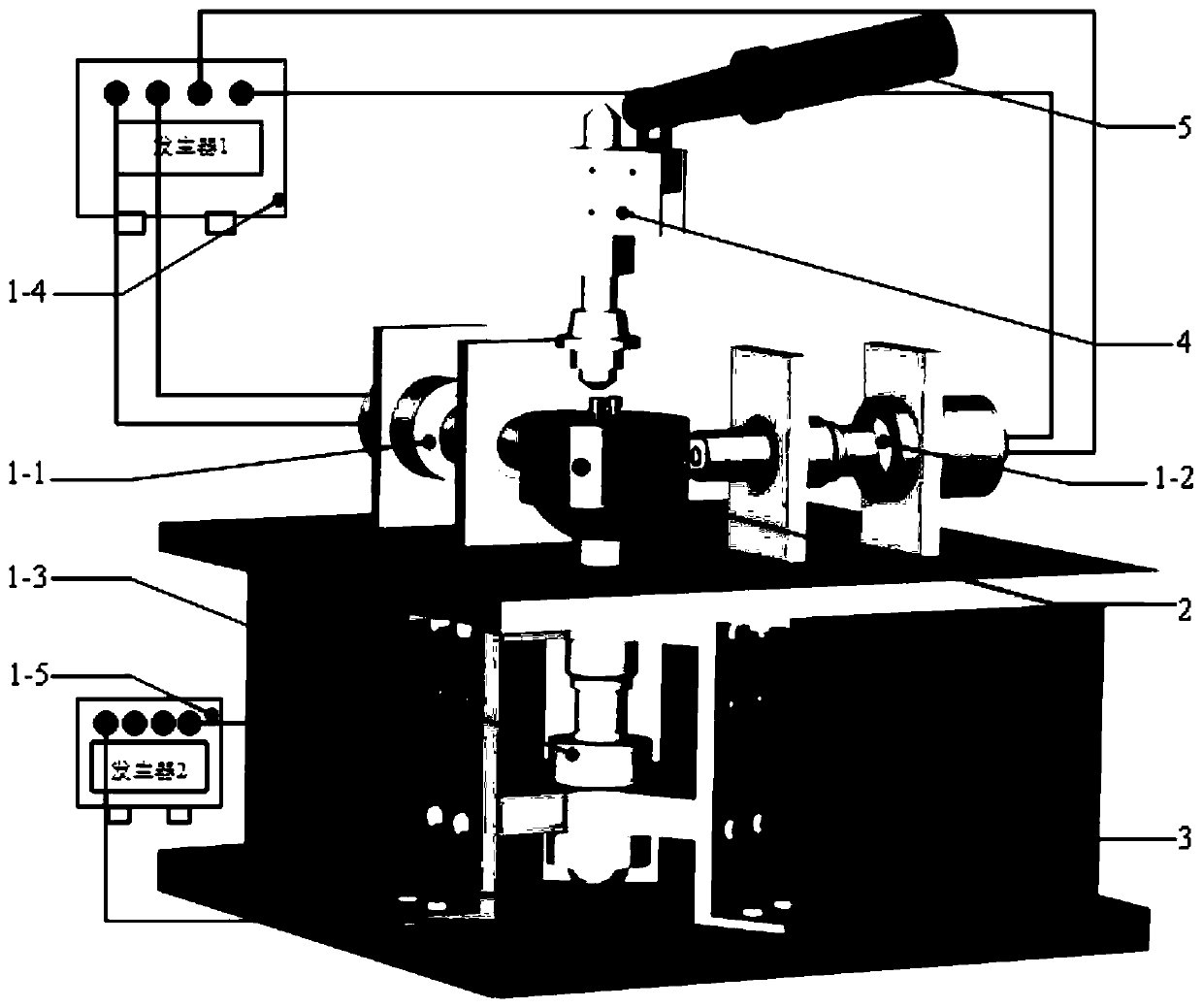

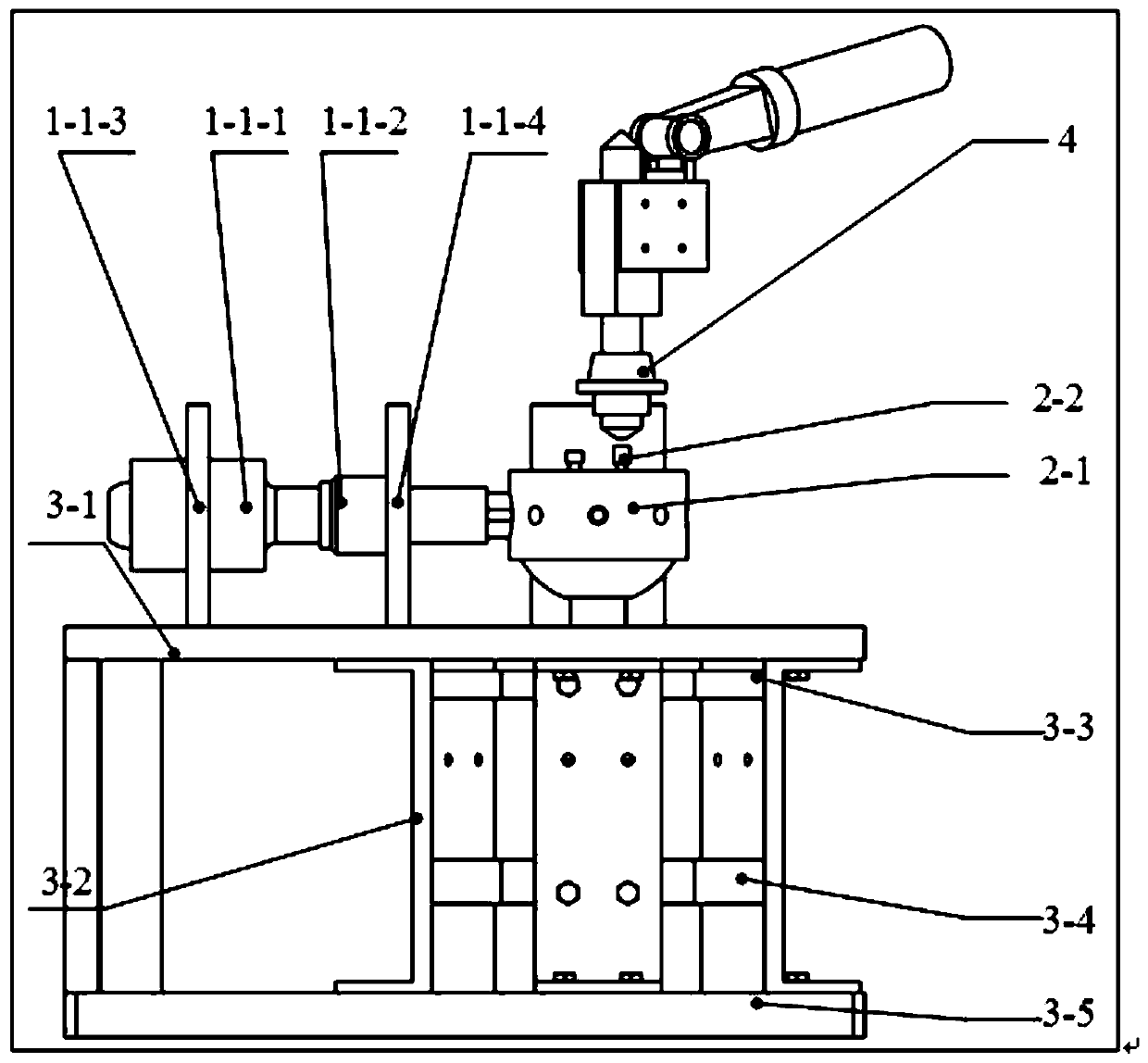

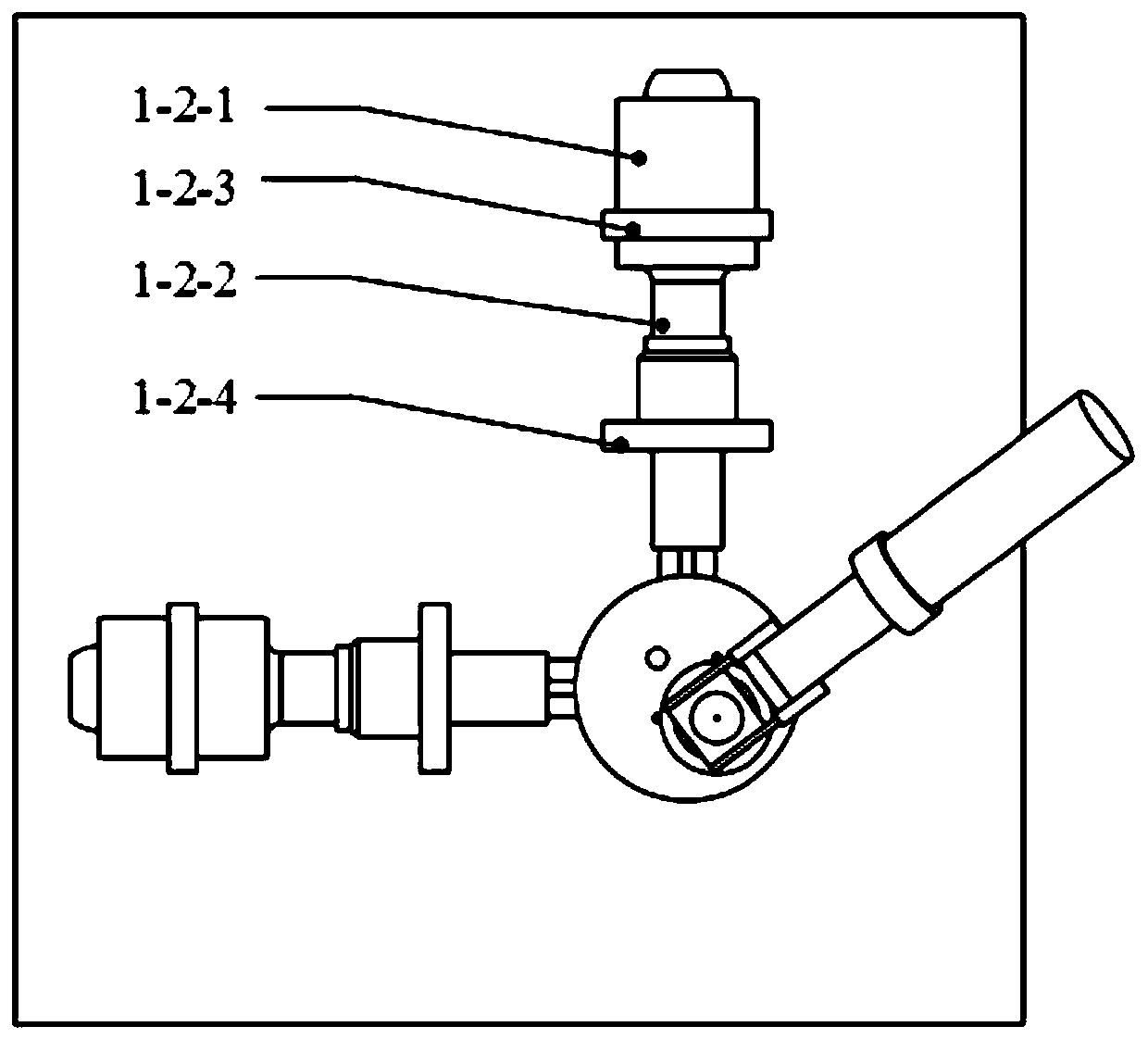

[0032] Such as Figure 1 to Figure 9As shown, the present invention provides a variable angle elliptical vibration-laser forming device and method for the preparation of a CBN grinding head, including a variable angle elliptical vibration device 1, a micro-grinding head base workbench 2, a vibration support platform 3, a laser melting The covering device 4 and the mechanical arm 5 are characterized in that: the variable-angle elliptical vibration device 1 is arranged on the vibration support platform 3, and the micro-grinding head base workbench 2 realizes the connection with the variable-angle elliptical vibration devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com