Diode lead sizing sealing device capable of achieving uniform sizing

A sealing device and diode technology, applied to the surface coating liquid device, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as bending and uniformity, and achieve improved contact area and uniform glue guarantee and improve the effect of contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

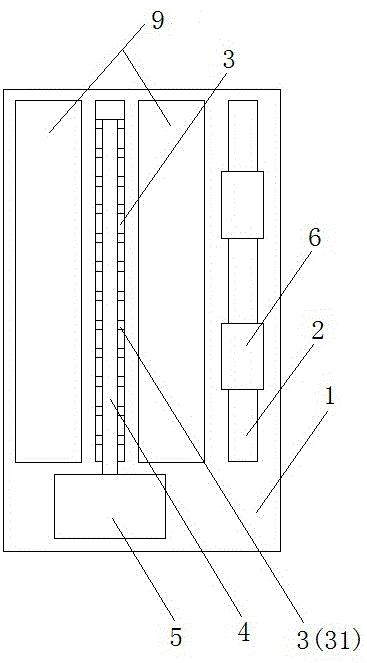

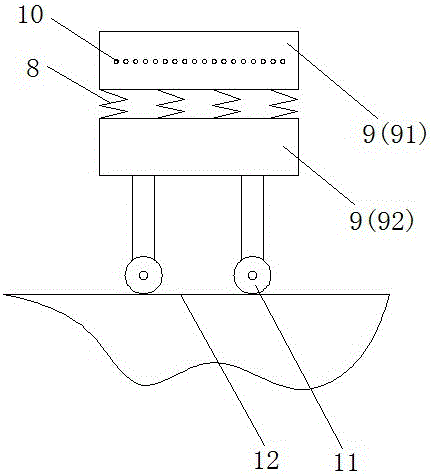

[0023] Such as figure 1 A diode lead wire sealing device that can achieve uniform gluing is shown, which includes a support platform 1, a transmission chain 2 for transporting diodes is arranged on the support platform 1, and a sealing device for sealing the diode leads. The rubber rack 3 contains a plurality of upwardly extending sealing teeth 31, and the sealing rack 3 extends parallel to the transmission chain 2; the sealing rack 3 is provided with a glue port 4, which communicates with the glue groove 5 provided in the support platform 1 .

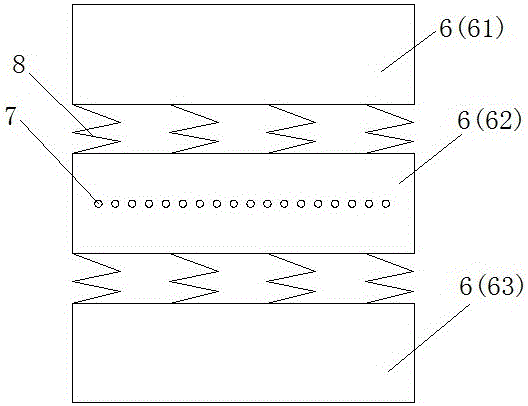

[0024] Such as figure 1 and figure 2 As shown, the diode lead wire sealing device that can realize uniform gluing is provided with a lead wire placement end block 6, which is fixed on the transmission chain 2, and a plurality of lead wires parallel to each other are arranged in the lead wire placement end block 6 Place the hole 7, the axis of the lead wire placement hole 7 extends perpendicular to the transmission chain 2; the lead...

Embodiment 2

[0033] As an improvement of the present invention, the diode lead wire sealing device capable of uniform gluing is provided with two lead support end blocks 6 , which are respectively located on both sides of the sealing rack 3 . With the above design, the diode lead wires can be respectively supported by the lead wire support end blocks located on both sides of the sealing rack, so that the supporting effect can be further improved.

[0034] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0036] As an improvement of the present invention, the vertical distance between the gluing port 4 and the gluing rack 3 is 0.2 centimeters, which can further ensure the connection between the lead wire of the diode and the gluing rack, and the gluing port. fit.

[0037] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com