Lower hopper ridge of hopper car

A funnel ridge and funnel car technology, applied in the field of vehicles, can solve the problems of increasing the load of the vehicle, the self-heaviness and disadvantages of the lower funnel ridge, etc., and achieve the effect of increasing the load of the vehicle, increasing the load, and reducing the self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

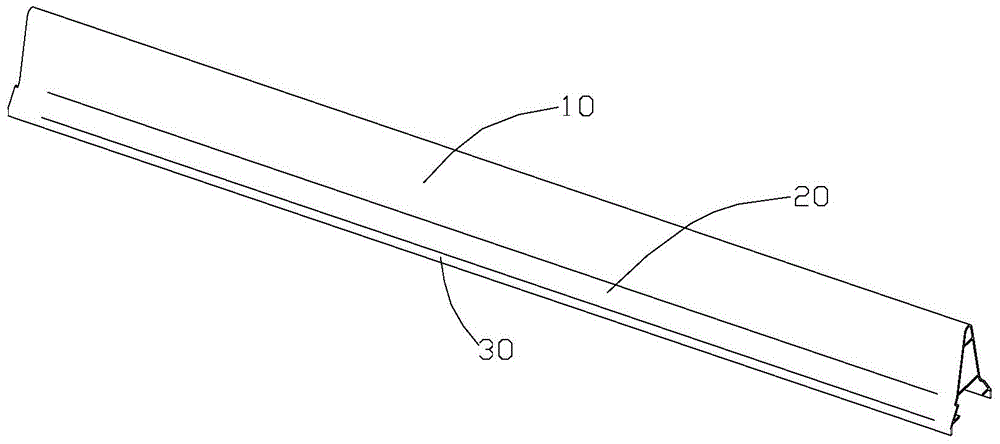

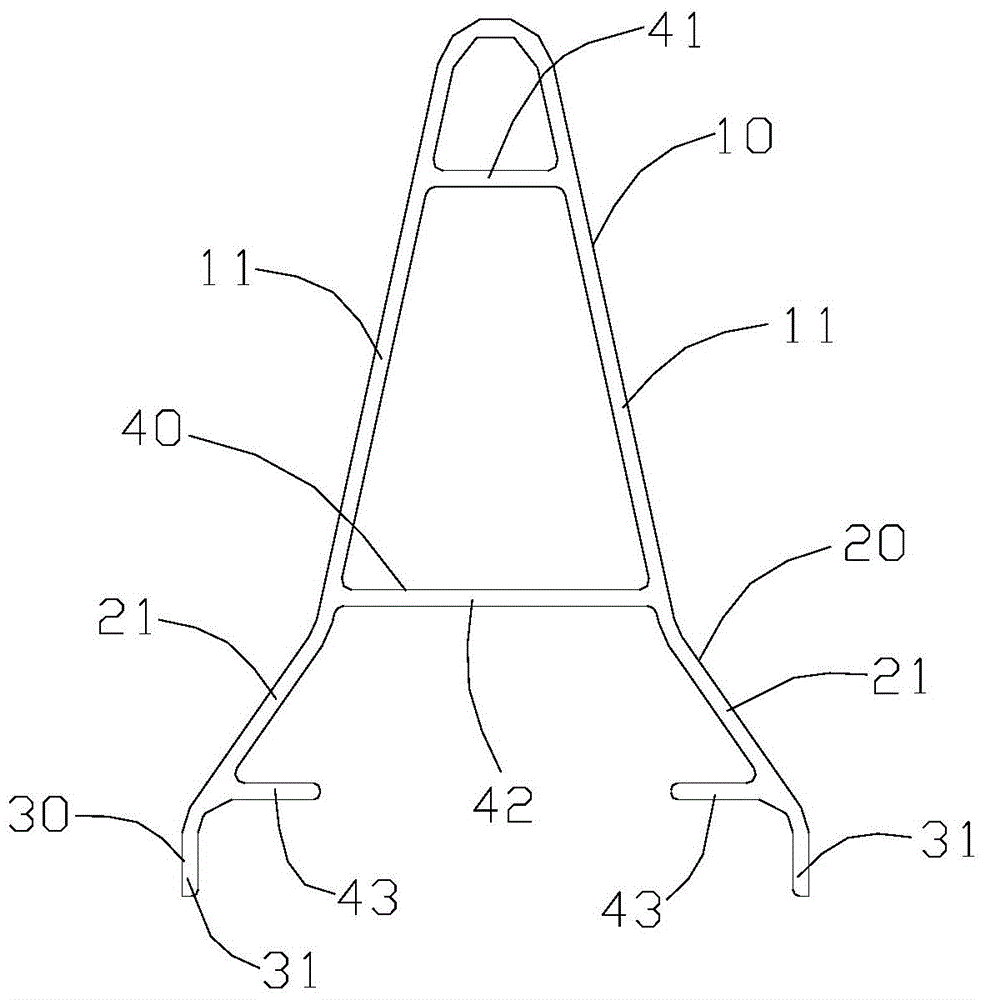

[0024] The embodiment of the present application provides a lower funnel ridge of a hopper car, which improves the technical problem in the prior art that the lower funnel ridge has a relatively large self-weight because the lower funnel ridge is a steel welded structure, which is not conducive to increasing the load capacity of the vehicle.

[0025] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0026] By setting the lower funnel ridge of the hopper car to be made of aluminum alloy material and integrally formed structure, and one end of the two side plates is fixedly connected at an acute angle to form the lower transverse ridge, and one end of the two connecting plates is respectively It is fixedly connected with the other end of the two side plates, the angle between the two connecting plates is greater than the angle between the two side plates, and the two suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com