High-efficiency divergent type microporous aerator

A microporous aerator, a divergent technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem of low utilization of aeration area and low utilization rate of aerator High pressure, high pressure in the upper part of the aerator, etc., to avoid sludge accumulation at the bottom of the pool, reduce the expansion volume, and prolong the residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

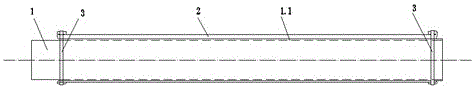

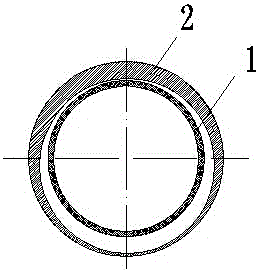

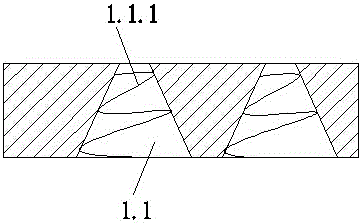

[0014] Embodiment 1: High-efficiency divergent microporous aerator, including a support tube 1, a membrane 2 set on the surface of the support tube 1, the support tube 1 is evenly distributed with aeration holes 1.1, and the support tube 1 is coated on the upper surface The thickness of the diaphragm 2 is greater than that of the diaphragm 2 covering the lower surface of the support tube 1 . The thickness of the diaphragm 2 on the upper surface of the support tube 1 is three times the thickness of the diaphragm 2 on the lower surface of the support tube 1 . The aeration hole 1.1 is a tapered hole with a large bottom and a small top, and a spiral notch 1.1.1 is processed in the tapered hole. The ratio of tapered hole to hole size is 2.8:1. Both ends of the diaphragm 2 are sealed and fixed with the support tube 1 by the hoop 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com