Acrylonitrile wastewater treatment method

A technology of acrylonitrile wastewater and treatment method, which is applied in natural water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of membrane pollution, increased treatment cost, and high treatment cost, and achieve efficient adsorption of pollutants , Improve fluidization effect, increase the effect of aeration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

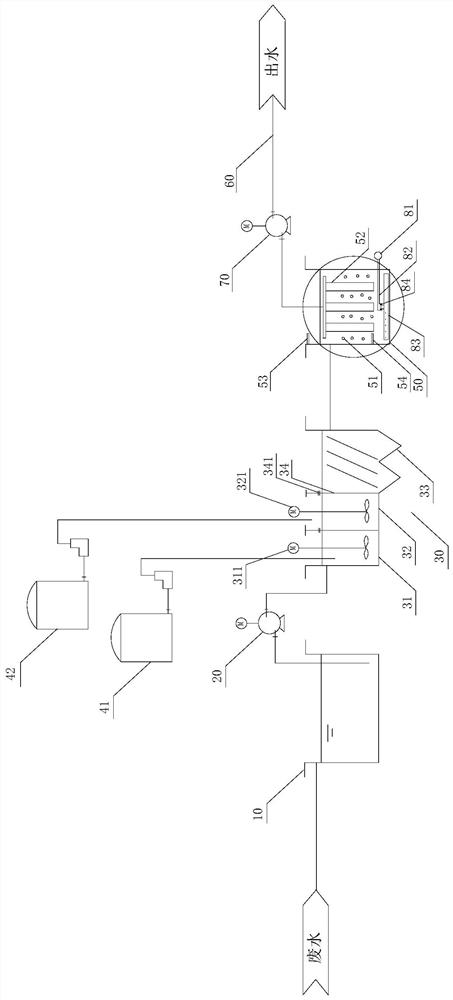

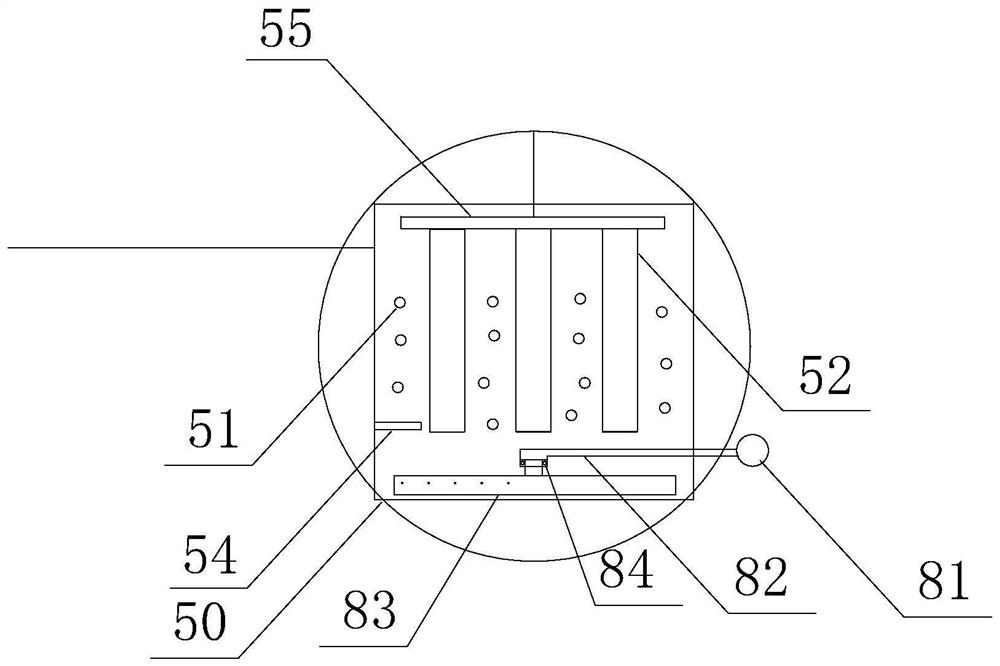

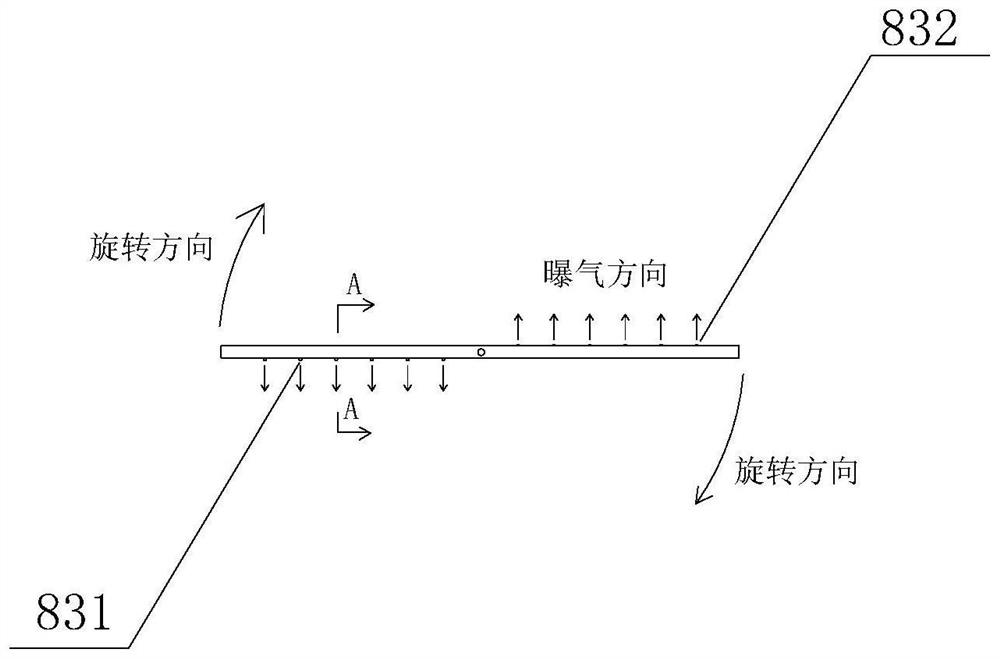

[0023] to combine Figure 1 to Figure 4 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

[0024] A method for treating acrylonitrile wastewater, which is carried out by using an acrylonitrile wastewater treatment system;

[0025]The acrylonitrile wastewater treatment system includes a sump 10, a lift pump 20, a coagulation sedimentation tank 30, a dosing device, a membrane pool 50, several flat membrane modules 52, a high level gauge 53, a low level gauge 54, Water collecting plate 55, outlet pipe 60, outlet pump 70, aeration device, controller, the lift pump 20 is used to lift the waste water in the sump 10 to the coagulation sedimentation tank 30, the coagulation sedimentation tank 30 Including the fast mixing zone 31, the slow mixing zone 32 and the sedimentation zone 33 which are sequentially separated by the partition plate 34, the upper part of each partition plate 34 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com