Machining device and machining technology for glass sheet hot bending molding

A technology for processing equipment and glass flakes, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., and can solve problems such as unfavorable development of glass flake hot-bending forming process, low total output of glass flakes, and low hot-bending efficiency. , to save resources, improve operating efficiency, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

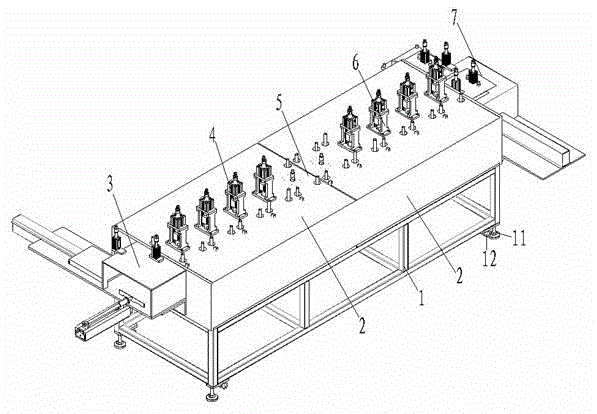

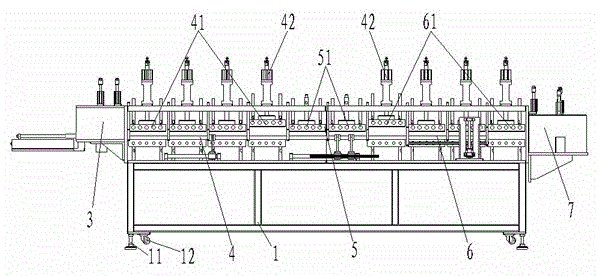

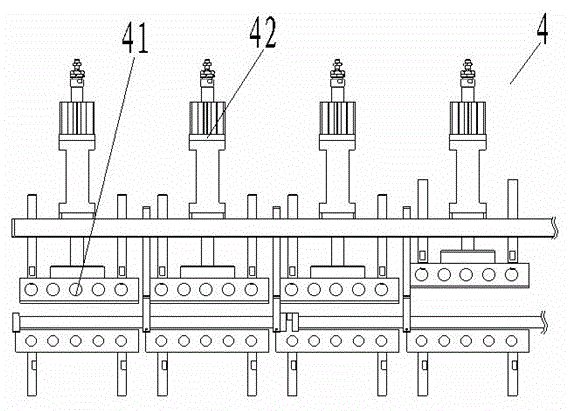

[0030] A kind of processing equipment for thermal bending and forming of glass sheets. The processing equipment mainly includes a whole machine stand and a support part 1. The whole machine stand is formed into a stand structure with a sealed periphery and a cavity inside. The sealed periphery is set by Surrounded by flat plates 2 in the upper, lower and surrounding directions, the support part 1 is arranged under the whole machine frame to support the whole machine frame, and the inner cavity of the whole machine frame is horizontally installed with preset Hot zone 4, forming zone 5 and cooling zone 6, fusion zones are installed at the left and right ends of the outside of the whole machine frame, and at the same time, the whole machine frame is provided with fusion zones connecting both ends and coherent preheating zone 4 and forming zone 5 and the conveying track of the cooling zone 6;

[0031] The left fusion zone 3 is mainly composed of a fusion cavity 31, a jig 32 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com