Compound multifunctional rubber processing peptizer and preparation method thereof

A multifunctional, peptizing agent technology, applied in the field of compound multifunctional rubber processing peptizing agent and its preparation, can solve environmental pollution and other problems, achieve the effects of reducing Mooney viscosity, improving fluidity, and improving plasticizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

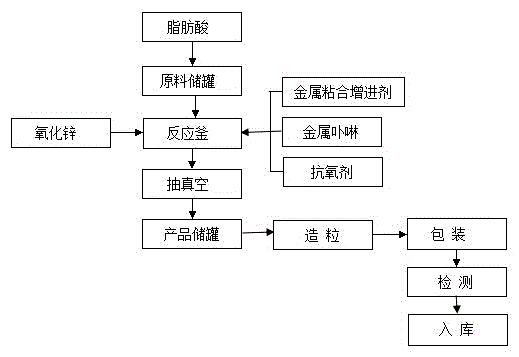

[0020] see figure 1 , in the embodiment of the present invention, a kind of composite multifunctional rubber processing peptizer, comprises according to the raw material of weight part: 900 parts of C8-C22 fatty acid, 140 parts of zinc oxide of indirect method, 5 parts of antioxidant, metal adhesion promoter 0.5 part of feed agent, 1 part of metalloporphyrin.

[0021] The preparation method of described composite multifunctional rubber processing peptizer, concrete steps are as follows:

[0022] (1) taking material: take each raw material according to parts by weight;

[0023] (2) Add fatty acid: put C8-C22 fatty acid in 2000L reaction kettle, stir and heat;

[0024] (3) add metal adhesion promoter, metalloporphyrin and antioxidant: when the temperature of reactor was 85 ℃, add metal adhesion promoter, metalloporphyrin and antioxidant successively;

[0025] (4) Add indirect method zinc oxide: when the temperature of the reactor reaches 95°C, add 48% of the total amount of i...

Embodiment 2

[0030] see figure 1 , in the embodiment of the present invention, a kind of composite multifunctional rubber processing peptizer, comprises according to the raw material of weight part: 1050 parts of C8-C22 fatty acid, 148 parts of indirect method zinc oxides, 6.5 parts of antioxidants, metal adhesion enhancer 1.3 parts of feed agent and 2.5 parts of metalloporphyrin.

[0031] The preparation method of described composite multifunctional rubber processing peptizer, concrete steps are as follows:

[0032] (1) taking material: take each raw material according to parts by weight;

[0033] (2) Add fatty acid: put C8-C22 fatty acid in 2000L reaction kettle, stir and heat;

[0034] (3) add metal adhesion promoter, metalloporphyrin and antioxidant: when the temperature of reactor was 92 ℃, add metal adhesion promoter, metalloporphyrin and antioxidant successively;

[0035] (4) Add indirect method zinc oxide: when the temperature of the reactor reaches 98°C, first add 50% of the to...

Embodiment 3

[0040] see figure 1 , in the embodiment of the present invention, a kind of composite multifunctional rubber processing peptizer, comprises according to the raw material of weight part: 1100 parts of C8-C22 fatty acid, 160 parts of zinc oxide of indirect method, 7 parts of antioxidant, metal adhesion enhancer 1.5 parts of feed agent and 3 parts of metalloporphyrin.

[0041] The preparation method of described composite multifunctional rubber processing peptizer, concrete steps are as follows:

[0042] (1) taking material: take each raw material according to parts by weight;

[0043] (2) Add fatty acid: put C8-C22 fatty acid in 2000L reaction kettle, stir and heat;

[0044] (3) add metal adhesion promoter, metalloporphyrin and antioxidant: when the temperature of reactor is 100 ℃, add metal adhesion promoter, metalloporphyrin and antioxidant successively;

[0045] (4) Add indirect zinc oxide: when the temperature of the reactor reaches 100°C, first add 52% of the total amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com