Intermediate-frequency quenching machine tool driven by motors

A quenching machine tool, motor-driven technology, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve problems such as affecting quenching accuracy, workpiece vibration, easy deformation, etc., to improve quenching stability and accuracy, reduce motor damage rate, prevent The effect of axial play

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

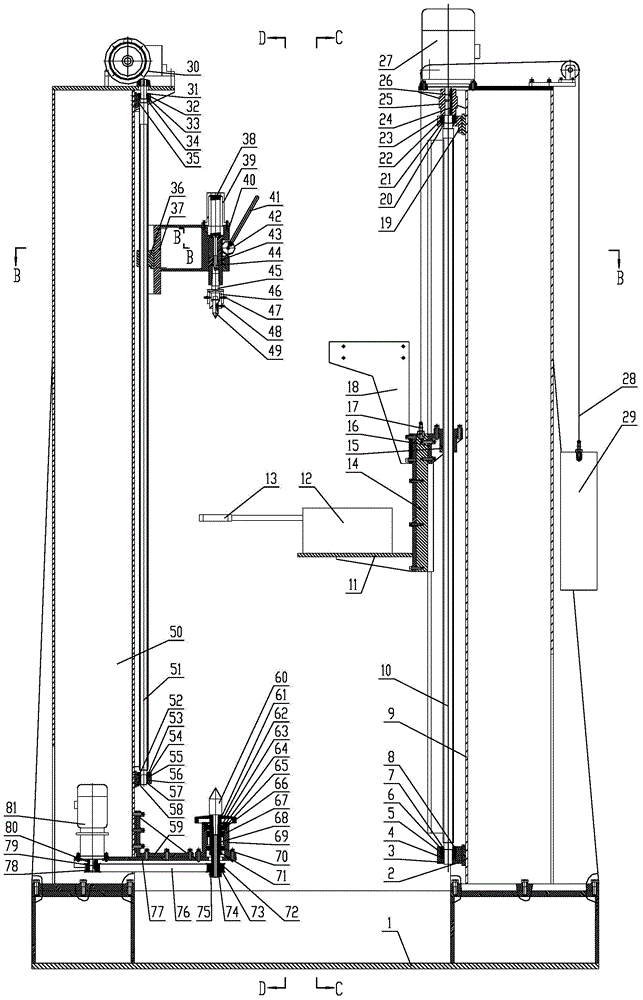

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

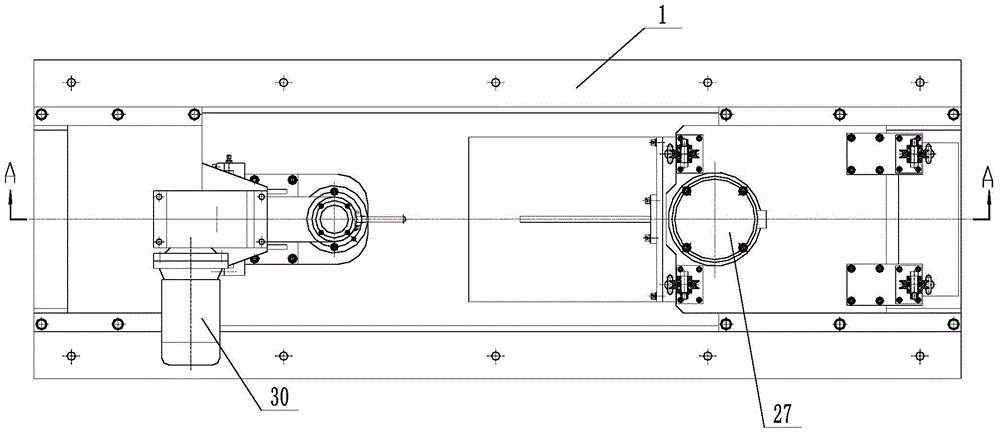

[0025] Such as Figure 1-Figure 5 As shown in the figure, the motor-driven intermediate frequency quenching machine tool fixes the base 1 on the ground and adjusts the level by 0.06mm / 1000mm.

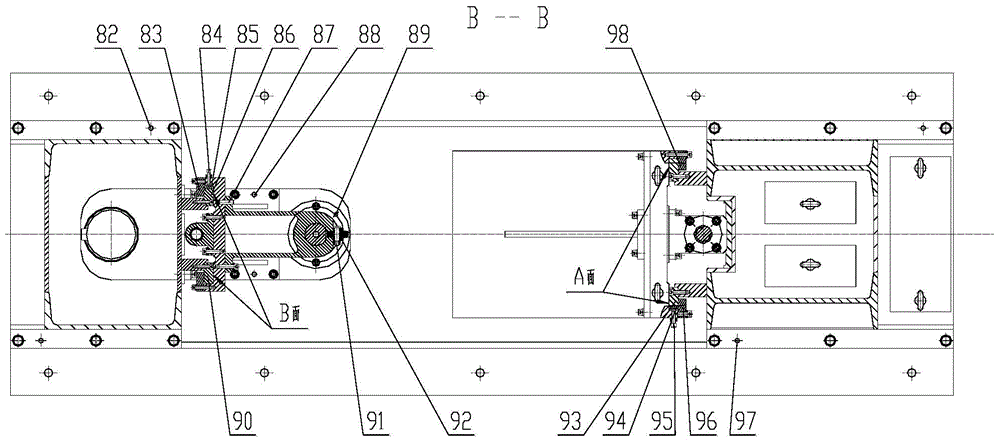

[0026] Install the guide rail Ⅲ93 and the guide rail Ⅳ98 on the column Ⅰ9 to ensure that the two planes A are on the same plane, the flatness error is not more than 0.08mm / 2000mm, and the parallelism error of the two sides is not more than 0.08mm / 2000mm. Drill the positioning pin hole and install it. Cylindrical pin VII100.

[0027] Install the guide rail Ⅰ86 and guide rail Ⅱ90 on the column Ⅱ50, ensure that the two planes B are on the same plane, the flatness error is not more than 0.08mm / 2000mm, and the parallelism error of the two sides is not more than 0.08mm / 2000mm, drill the positioning pin hole, install Cylindrical pin X109.

[0028] Install the column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com