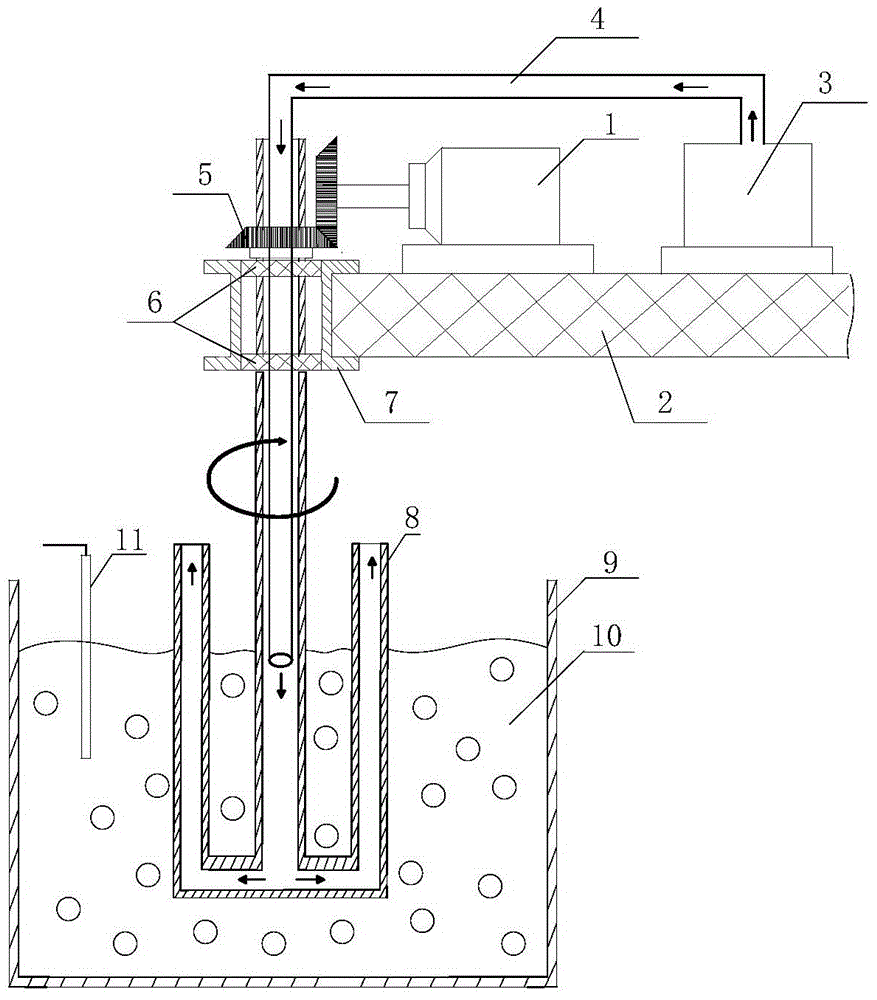

An air-cooled multi-tube stirring device and method for preparing light alloy semi-solid slurry

A technology for semi-solid slurry and light alloy, which is applied in the field of equipment for preparing light alloy semi-solid slurry by air-cooled multi-tube stirring, and can solve the problem of difficulty in preparing large-volume semi-solid slurry and industrialization promotion, poor reliability of continuous operation, and cleaning. Cumbersome maintenance and other problems, to achieve the effect of easy industrialization and application, a wide range of applicable alloys, and a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

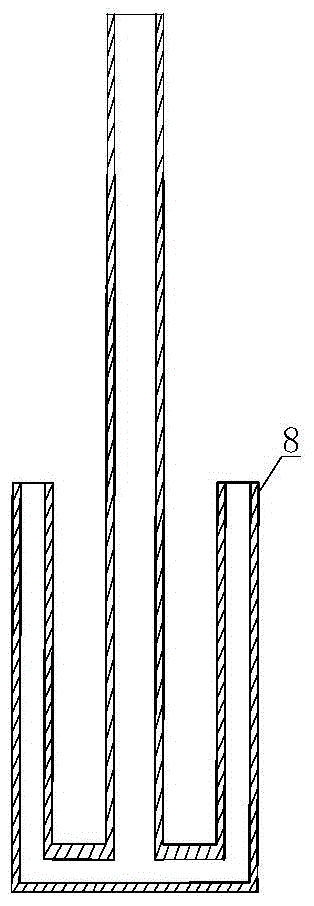

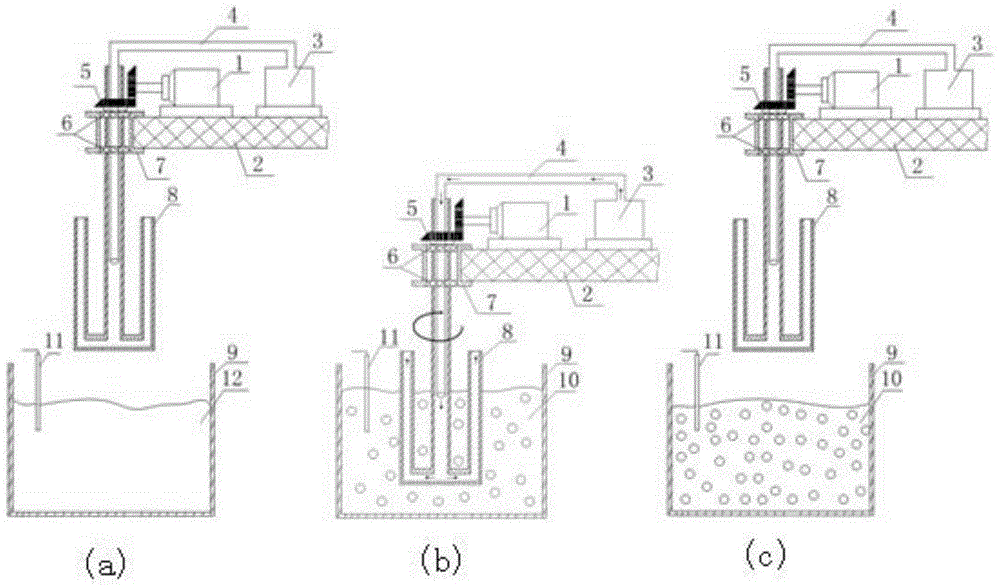

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Comparison of A380 aluminum alloy semi-solid slurry prepared by ordinary stirring mechanism, air-cooled single-tube stirring mechanism and air-cooling multi-tube stirring mechanism, the steps are as follows:

[0061] (1-1) The liquidus and solidus temperatures of the A380 die-casting aluminum alloy used in the test are 585°C and 504°C, respectively. The aluminum alloy ingot is placed in a crucible resistance furnace with a preheating temperature of 250°C. Refining after the liquid temperature rises to 690°C, press the dried hexachloroethane into the bottom of the aluminum alloy liquid with a bell jar, the amount added is 0.5% of the total weight of the aluminum alloy liquid, shake gently to degas the melt , slag removal and refining treatment, and finally cool down the aluminum alloy melt to 610°C and keep it warm.

[0062] (1-2) The stirring speed of the multi-tube stirring rod in the preparation device is 400r / min, the air intake in the air duct is 300L / min...

Embodiment 2

[0065] Embodiment 2: Preparation of A356 cast aluminum alloy semi-solid slurry, the steps are as follows:

[0066](2-1) The liquidus and solidus temperatures of the A356 cast aluminum alloy used in the test are 615°C and 556°C, respectively. Put the aluminum alloy ingot into a crucible resistance furnace with a preheating temperature of 300°C, Refining after the liquid temperature rises to 700°C, press the dried hexachloroethane into the bottom of the aluminum alloy liquid with a bell jar, the amount added is 0.5% of the total weight of the aluminum alloy liquid, shake gently to degas the melt , slag removal and refining treatment, and finally cool the aluminum alloy melt to 650°C and keep it warm.

[0067] (2-2) The stirring speed of the multi-tube stirring rod in the preparation device is 400r / min, the air intake in the air duct is 400L / min, the inner diameter of the air duct is 10mm, there are 3 stirring tubes, the wall thickness of the stirring tube is 5mm, and the inner d...

Embodiment 3

[0068] Embodiment 3: Preparation of 7075 deformed aluminum alloy semi-solid slurry, the steps are as follows:

[0069] (3-1) The liquidus and solidus temperatures of the 7075 deformed aluminum alloy used in the test are 635°C and 477°C, respectively. Put the aluminum alloy ingot into a crucible resistance furnace with a preheating temperature of 300°C, Refining after the liquid temperature rises to 720°C, press the dried hexachloroethane into the bottom of the aluminum alloy liquid with a bell jar, the amount added is 0.5% of the total weight of the aluminum alloy liquid, shake gently to degas the melt , slag removal and refining treatment, and finally cool the alloy melt to 660°C and keep it warm.

[0070] (3-2) The stirring speed of the multi-tube stirring rod in the preparation device is 300r / min, the air intake in the air duct is 300L / min, the inner diameter of the air duct is 10mm, there are 3 stirring tubes, the wall thickness of the stirring tube is 5mm, and the inner d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com