Corrosion inhibitor for pickling of hot-rolled automobile structural steel and preparation and use method thereof

A technology of automobile structure and corrosion inhibitor, which is applied in the field of hot-rolled carbon steel anti-corrosion and hot-rolled pickling strip pickling corrosion inhibitor, can solve the problem of decreased hydrochloric acid consumption, high acid pickling corrosion inhibition rate and low addition amount and other problems, to achieve the effect of reducing the corrosion rate of steel plates, simple production process and low usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the composite corrosion inhibitor that the present invention relates to is:

[0029] ① Add 70kg of water to the container;

[0030] ②Polyepichlorohydrin quaternary ammonium salt 5kg, stir evenly and place;

[0031] ③ Add 10kg of thiourea to ②, stir evenly and wait for use;

[0032] ④Heat phytate 10kg in the above-mentioned container and stir evenly;

[0033] ⑤ Add 5kg of citric acid and stir evenly, and the compound corrosion inhibitor is prepared.

[0034] The hot-rolled pickling line uses HCl solution, and the prepared corrosion inhibitor is added to the hot-rolled pickling line acid tank. The free acid HCl concentration of the hot-rolled pickling line is 100-120g / L; the pickling temperature is 70-80 ℃, the pickling speed is 80-150m / min; the amount of corrosion inhibitor added is 0.05%-0.1% of the total weight of the HCl acid solution (the total amount of acid solution in the acid tank is about 200 tons, and the amount of corrosion inhibit...

Embodiment 2

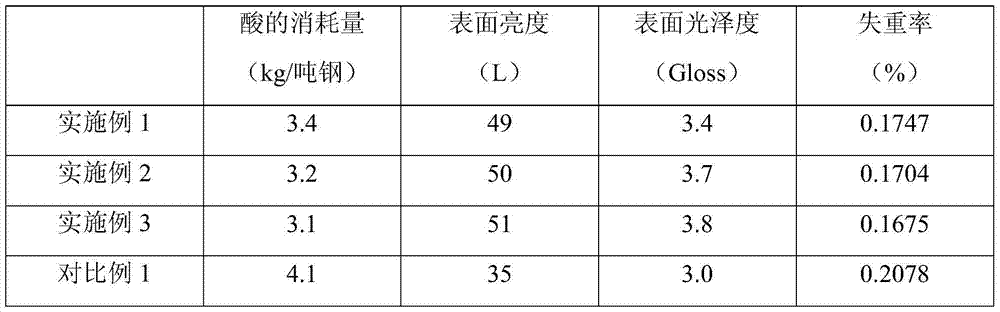

[0040] The preparation method is the same as in Example 1, except that the ratio of raw materials is different: 7 kg of polyepichlorohydrin quaternary ammonium salt; 8 kg of thiourea; 8 kg of phytic acid ester, 4 kg of citric acid, and 73 kg of water. The acid consumption, surface brightness, surface gloss, weight loss rate and other indicators are shown in Table 1.

Embodiment 3

[0041] The preparation method of Example 3 is the same as that of Example 1, except that the proportion of raw materials is different: 10 kg of polyepichlorohydrin quaternary ammonium salt; 5 kg of thiourea; 5 kg of phytate, 3 kg of citric acid, and 77 kg of water. The acid consumption, surface brightness, surface gloss, weight loss rate and other indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com