Upward inverse well drilling process

A technology of raising drilling rig and process, which is applied in the direction of drilling equipment, drill pipe, drilling pipe, etc. It can solve the problems of consuming a lot of manpower and material resources, not showing advantages, and consuming a lot of man-hours, so as to reduce man-hours and solve large-scale machinery handling Difficulty, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Pre-support is required for tunnel excavation and shaft excavation in areas with unstable strata to prevent accidents caused by landslides, which is the basic requirement for underground construction in areas with unstable strata.

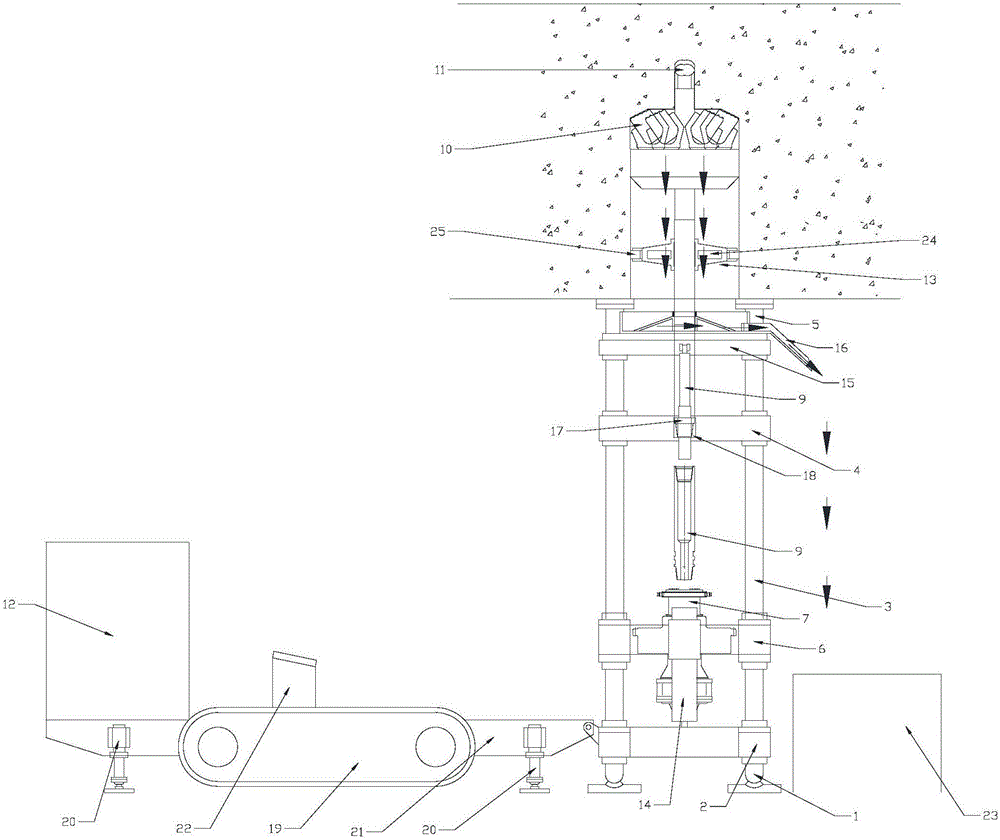

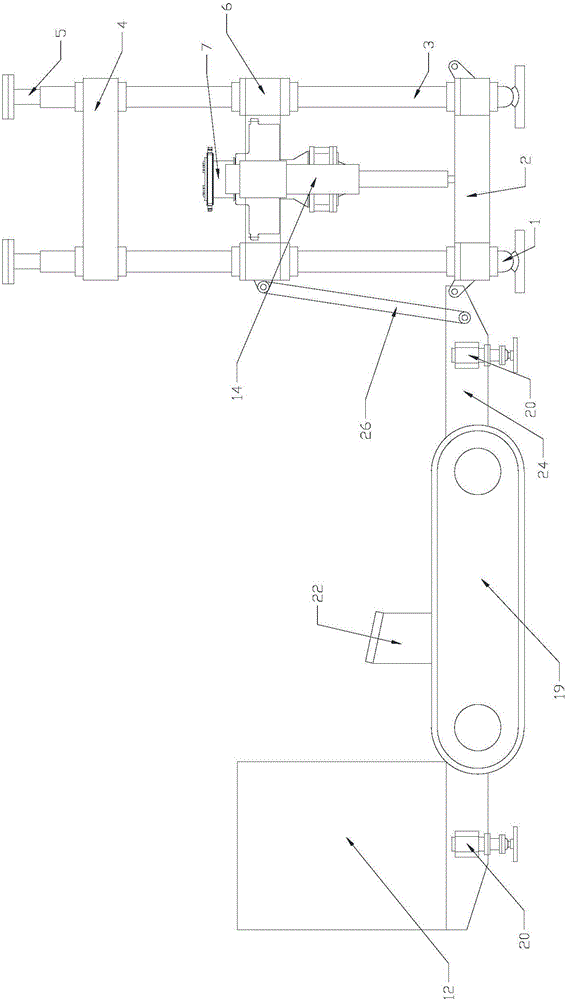

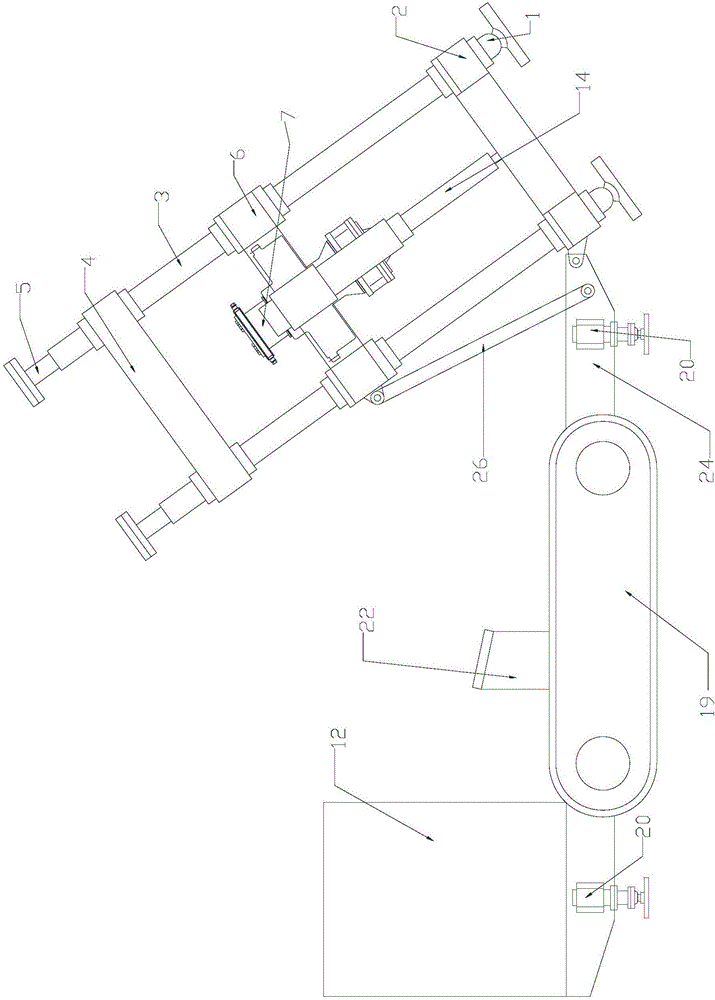

[0039] The upward raising drilling rig used in the present invention is a mobile upward raising drilling rig, such as Figure 1~4 As shown, the mobile upward drilling rig includes a drilling device and a moving device.

[0040] Wherein, the drilling device includes a drilling rig support mechanism, a main thrust cylinder 6, a power head 7 and a drilling tool, and the drilling rig support mechanism includes a lower support 1, a base 2, a guide column 3, a top beam 4 and an upper support 5; The upper end of the support 1 is fixedly connected with the lower end of the guide column 3, and the upper end of the guide column 3 is fixedly connected with the lower end of the upper support 5; On the guide column 3, the top beam 4 is installed on the ...

Embodiment 2

[0053] The mobile upward raising drilling machine used in this embodiment is the same as the mobile upward raising drilling machine used in Embodiment 1.

[0054] For areas with stable formations, simple protective treatment can be carried out in the existing tunnels to drill the formations above the tunnels, such as installing protective nets on the formations around the wellhead of the wellbore to be drilled, and the protective nets can be drilled in the wellbore. After it is completed, it is disassembled and continued to be used in the construction of the next wellbore drilling.

[0055] Similar to drilling the formation above the tunnel in the existing tunnel in the area with unstable formation, in the area with stable formation, the drilling construction of the formation above the existing tunnel also needs to study and analyze the geological conditions of the formation to be drilled. According to the geological data provided by the geological and design departments, cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com