Horizontal well jarring jam releasing device and construction method thereof

A horizontal well and jarring technology, which is applied to earth-moving drilling, wellbore/well components, etc., can solve the problems of unsatisfactory jarring effect, inability to produce jarring, and large wellbore friction, so as to reduce operating costs and improve The success rate and the economic benefits are remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

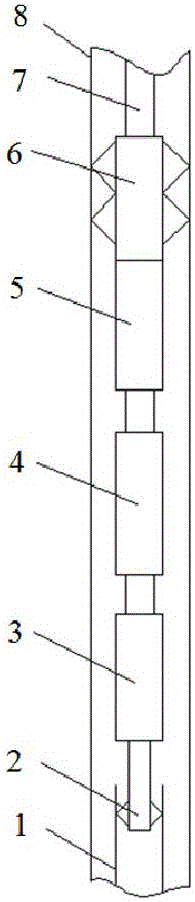

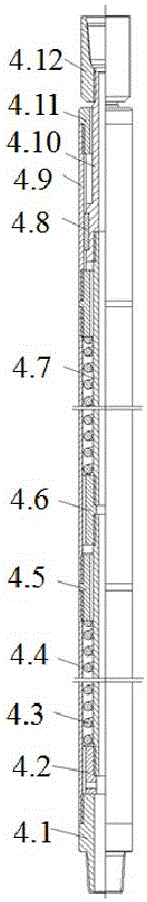

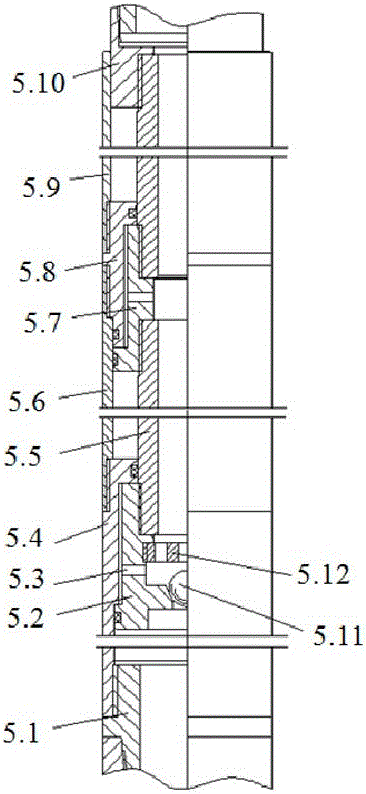

[0023] Below in conjunction with accompanying drawing, describe the present invention in detail, not limit protection scope of the present invention. see figure 1 with figure 2 , a jarring release device for a horizontal well includes a jar 3 and a jar booster 5 . The jar 3 is connected by the lower joint 3.1 of the jar, the guide head 3.2, the cylinder sleeve of the jar 3.6, the connection sleeve of the jar 3.8, the spline sleeve 3.10, and the mandrel 3.11 through threads in sequence, and the seals of each connection are uniform. Sealed by the seal ring 3.7, a tapered piston 3.5 is installed between the lower part of the mandrel 3.11 and the annulus of the jar cylinder sleeve 3.6, the tapered piston 3.5 is set on the throttle sleeve 3.4, the tapered piston 3.5 and the jar fluid The inner wall of the cylinder liner 3.6 forms a rigid-to-rigid sliding seal, forming a hydraulic delay mechanism. The upper part of the jar liner 3.6 is provided with a diameter-expanding section, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com