Bothway multiple-joint oil cylinder protection energy-saving hydraulic system

A hydraulic system and hydraulic cylinder technology, applied in fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve problems such as limiting piston retraction speed, reversing valve heating, equipment damage, etc., to achieve reduction The effect of small oil discharge resistance and increased return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

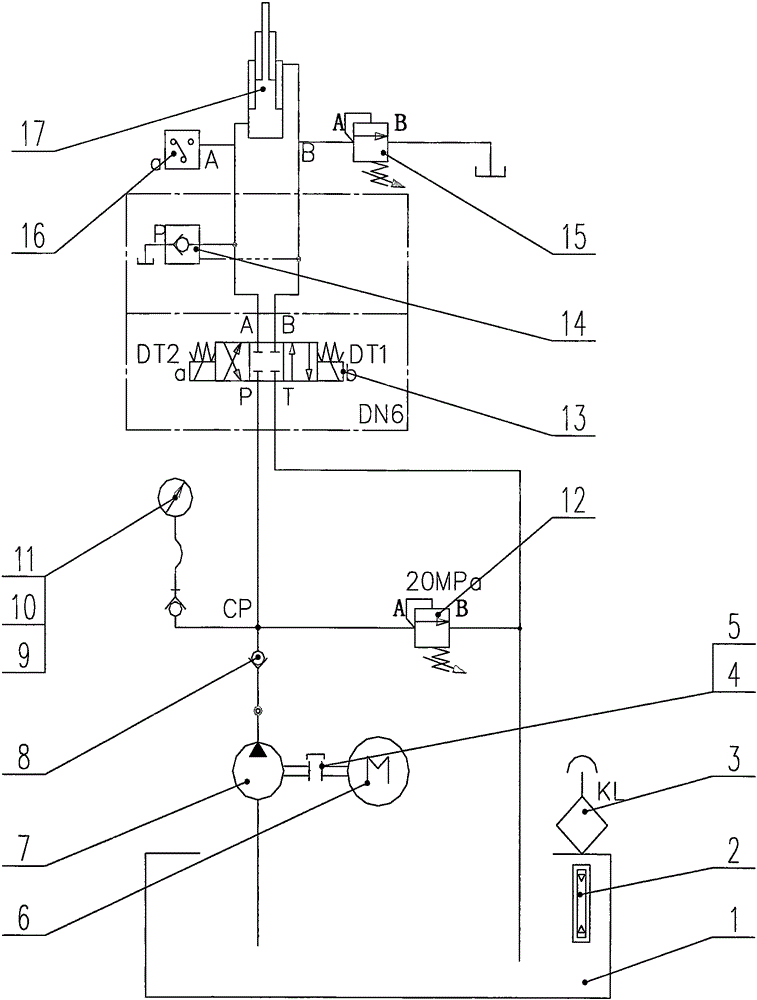

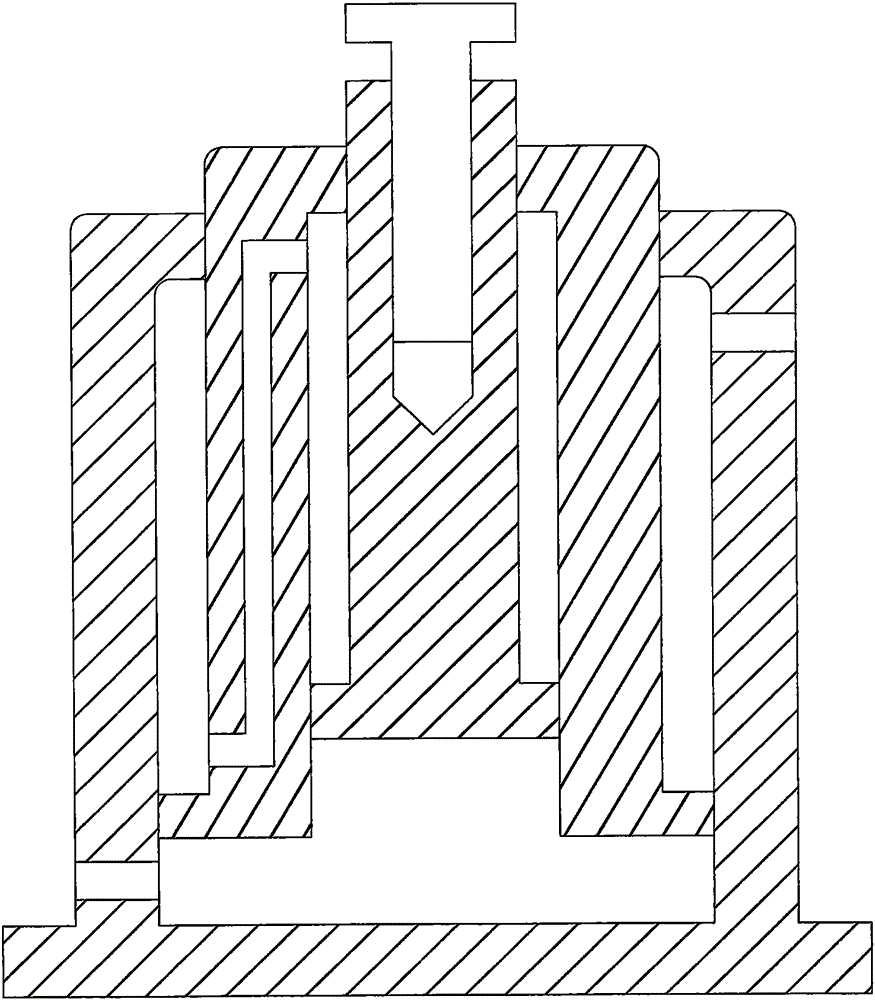

[0013] Attached below figure 1 , 2 , through the description of the embodiments, the specific implementation of the present invention is further described in detail.

[0014] Such as figure 1 As shown, the motor 6 is connected to the gear pump 7 through the coupling 4, the oil inlet pipe of the gear pump 7 is connected to the oil tank 1 storing the oil, and the oil pipe at the oil outlet is connected in series with a one-way valve 8, and the one-way valve 8 can be To prevent the system pressure from suddenly rising and being transmitted back to the hydraulic pump 7, to avoid pump reversal or damage, and to protect the hydraulic pump 7; at the same time, there are two bypass connections on the oil circuit between the check valve 8 and the electromagnetic reversing valve 13 Oil circuit, one is connected to the overflow valve 12, the pressure oil port of the valve is connected to the oil circuit, and the oil return port is connected to the oil tank 1, this valve is used to keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com