Magnetorheological damper with stepless and adjustable damping force

A magnetorheological shock absorber and damping force technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of incapable of damping, fixed and complex structure, etc. Achieve the effect of continuously variable damping force, prolong service life and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

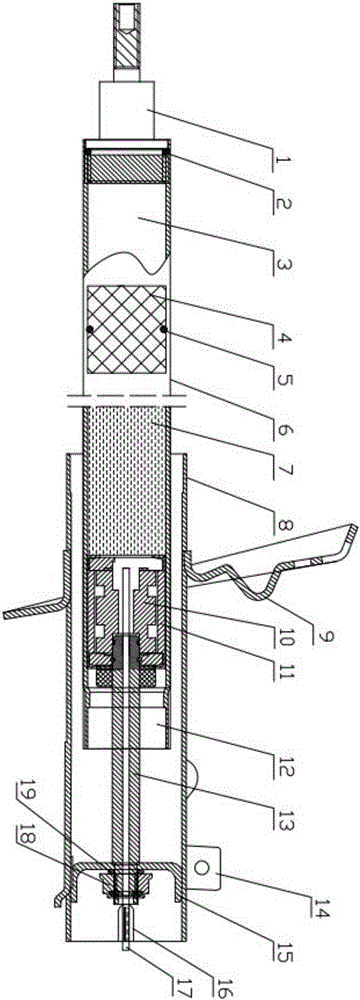

[0033] Such as Figures 1 to 4 As shown, a magnetorheological shock absorber with steplessly adjustable damping force, the magnetorheological shock absorber includes an outer cylinder assembly, an inner cylinder assembly and a piston rod assembly, and the outer cylinder assembly is set On the periphery of the inner cylinder assembly, the piston rod assembly is arranged inside the inner cylinder assembly and the outer cylinder assembly.

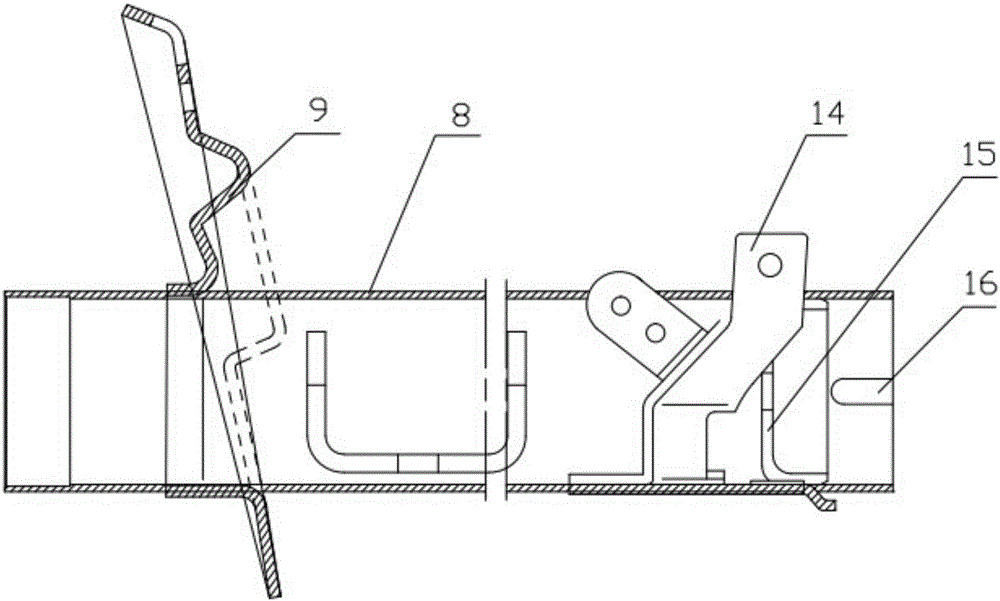

[0034] The outer cylinder assembly mainly includes an outer cylinder 8, a spring tray 9 arranged on the outside of the outer cylinder 8 for supporting the limit damping spring, an oil pipe fixing bracket 14 arranged on the outside of the outer cylinder 8 for fixing the oil pipe, and a set The piston rod fixing bracket 15 used for fixing the piston rod 13 is used for fixing the piston rod 13 at the inner rear end of the outer cylinder 8 .

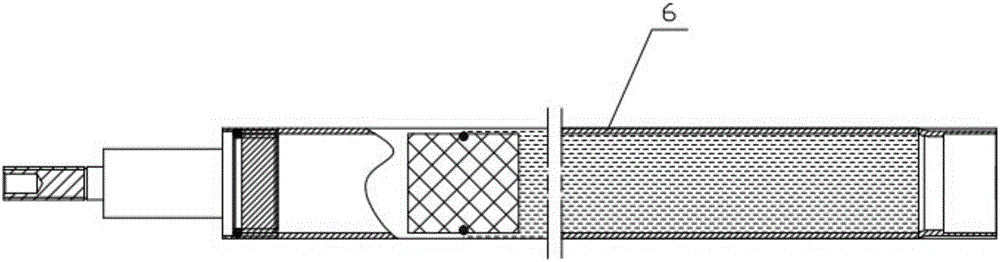

[0035] The inner cylinder assembly mainly includes an inner cylinder 6; a floating valve body 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com