Control method of multi-machine-head variable-frequency centrifugal central air conditioning unit

A technology of central air conditioning and control method, which is applied in the control input involving air characteristics, space heating and ventilation control input, heating and ventilation control system, etc., can solve the problem of not being able to exert the highest energy efficiency of the compressor, and achieve the best energy efficiency state. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

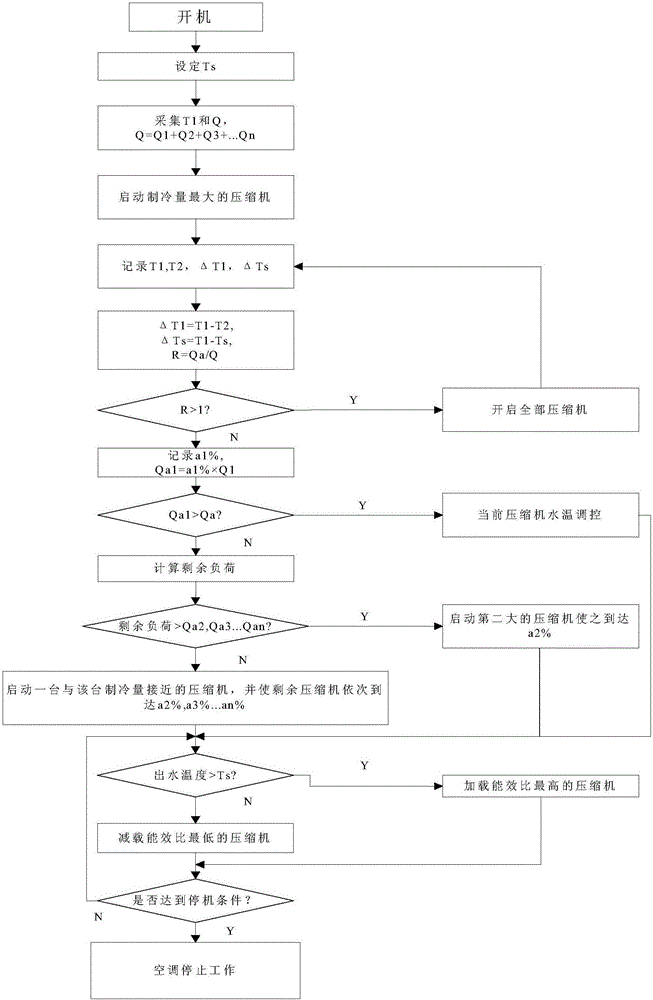

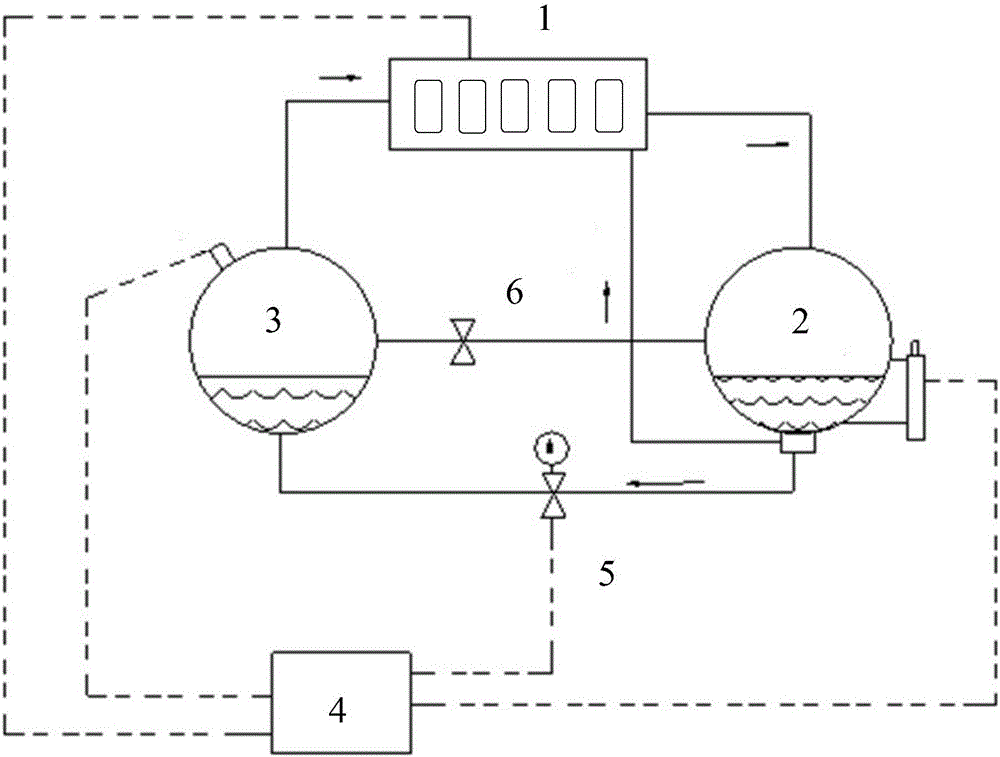

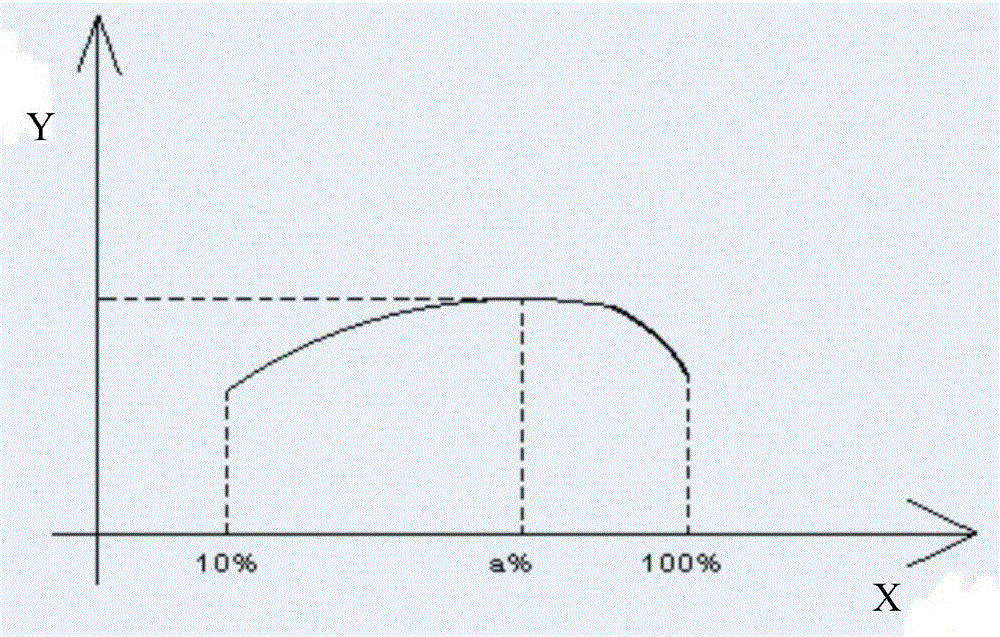

[0026] A control method for a multi-head variable-frequency centrifugal central air-conditioning unit. The hardware system includes a condenser 2 connected in sequence, a bypass valve 6, an evaporator 3, and three compressors 1 connected in parallel. The outlet of the condenser 2 is connected to the evaporator The inlet of the device 3 is connected, and an electronic expansion valve 5 is arranged between; the compressor 1, the condenser 2 and the evaporator 3 are connected to the input end of the external computer controller 4, and the output end of the computer controller 4 is connected to the electronic expansion valve 5 connected; the refrigerant flows in the circulation pipeline, and the steps of the control method are as follows:

[0027] (1) Set the target temperature Ts when the chilled water is discharged;

[0028] (2) collect the cooling total amount Q=Q1+Q2+Q3 of all compressors 1 of the central air-conditioning unit;

[0029] (3) collect the initial water inlet tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com