Leakproofness detection method for drain plug of ship bottom in ship construction

A technology for draining plugs and ship bottoms, applied in directions such as detecting the presence of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve difficulties, poor structural integrity of the cabin, and pressure that cannot meet the requirements of the draining plug Actual pressure and other issues, to achieve the effect of reducing construction costs, saving construction time, and testing results are true and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A method for detecting the tightness of ship bilge discharge in shipbuilding according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

[0033] The invention is a method for detecting the tightness of the ship's bottom drain plug in shipbuilding. The method adopts a new idea and operation process to detect the tightness of the ship's bottom drain plug, which has a safe and efficient detection effect, and The operation is simple and does not damage the hull.

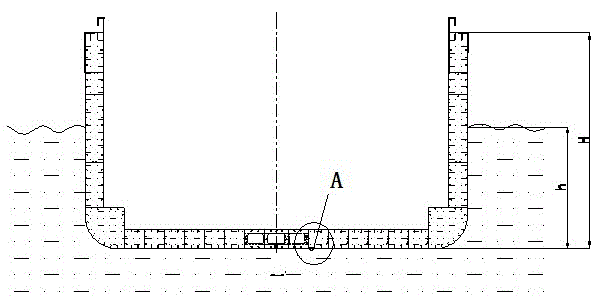

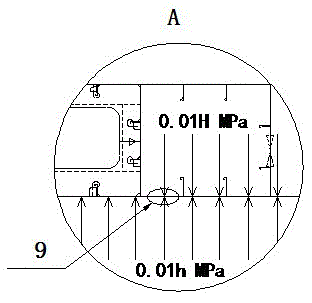

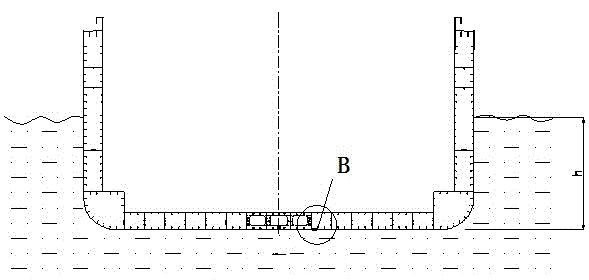

[0034] We first take three typical states of ballast water in the ship's ballast tank to analyze the pressure on the bottom drain plug, and take the maximum pressure under these three states as the test pressure.

[0035] figure 1 is an analysis diagram of the pressure on the discharge plug at the bottom of the ship when the ballast tank is fully lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com