Optical fiber tapering characteristic based system for detecting liquid refractive index in real time

A liquid refractive index, real-time detection technology, applied in the direction of phase influence characteristic measurement, etc., can solve the problems of complicated manufacturing process, high cost, and no popularization and application, and achieve simple operation and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

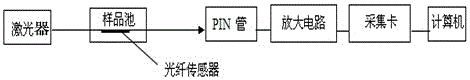

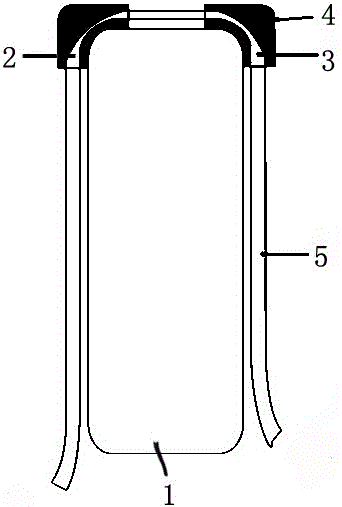

[0011] Such as figure 1 and figure 2 As shown, a system of real-time detection of liquid refractive index based on optical fiber tapering characteristics of the present invention, said system includes a specific wavelength laser, an optical fiber sensor, a PIN tube, an amplifier circuit, an acquisition card, a computer, and a sample pool to be detected, The optical fiber sensor is installed in the sample cell, and the laser emits light of a specific wavelength through the optical fiber sensor and the PIN tube in turn, and then the signal detected by the PIN tube is processed by the amplification circuit into an electrical signal, and is collected by the acquisition card. final transmission to a computer;

[0012] Wherein, the optical fiber sensor is composed of a rectangular plastic plate 1 and a single-mode optical fiber 5, the four corners of the plastic plate 1 are rounded, and the single-mode optical fiber 5 is fixed on the plastic by epoxy glue 4. On the two rounded co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com