Inspection device for outer wall of reactor pressure vessel bottom head penetration

A pressure vessel and inspection device technology, which is applied in reactors, nuclear reactor monitoring, nuclear power generation, etc., can solve the problems of unrealized installation and working environment, and achieve the effects of easy inspection operation, small volume and weight, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

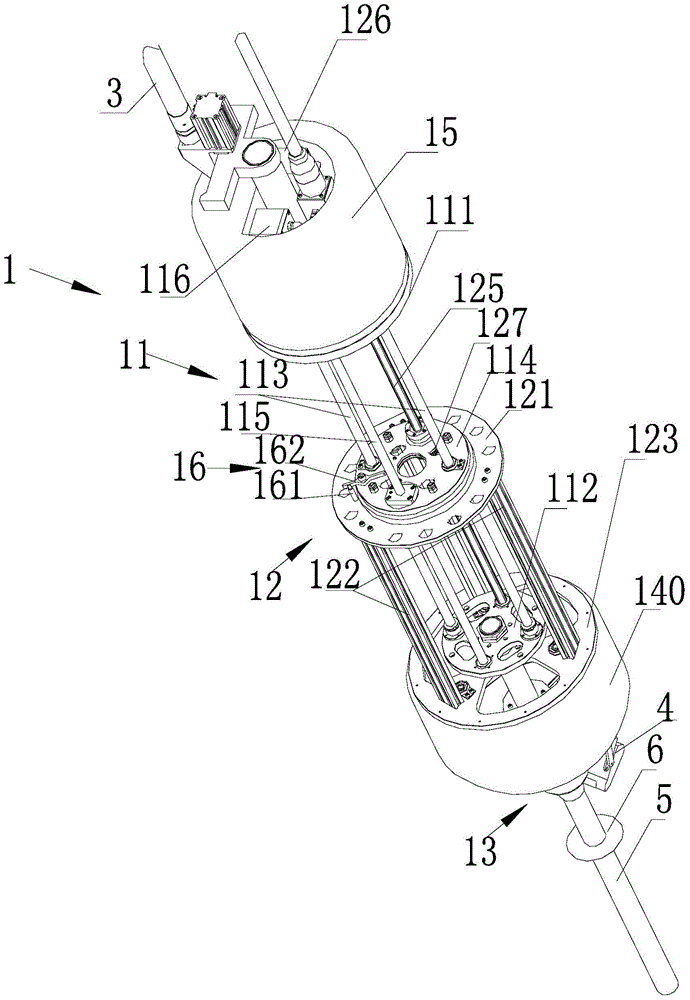

[0023] The inspection device for the outer wall of the penetrating part of the bottom head of the reactor pressure vessel is sent to the penetrating part 5 by the operation platform and the long rod assembly 3 connected between the operation platform and the outer wall inspection device 1 .

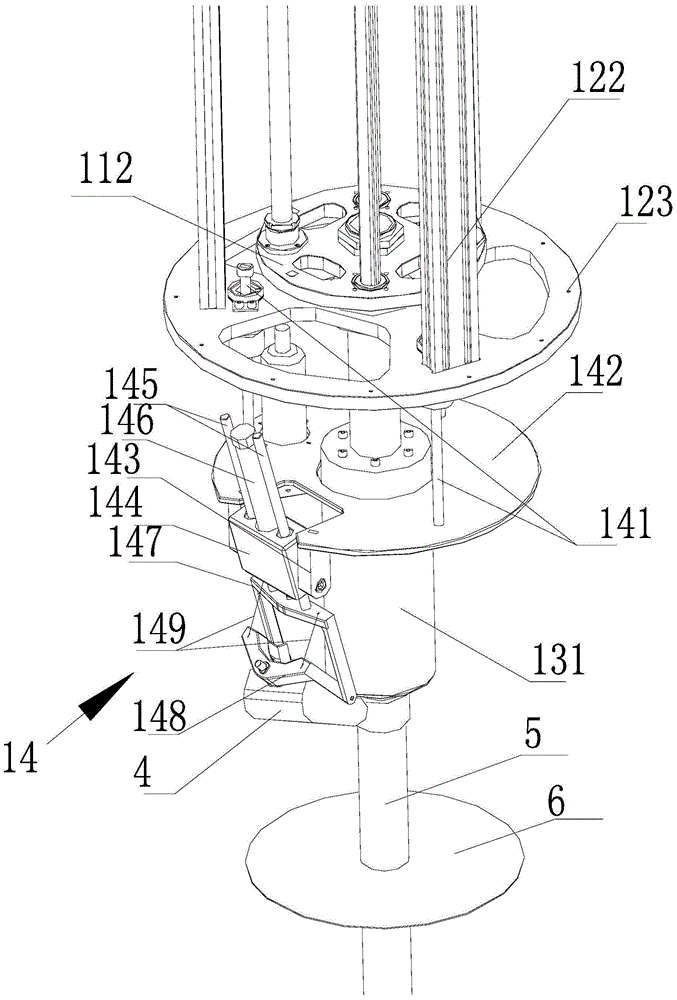

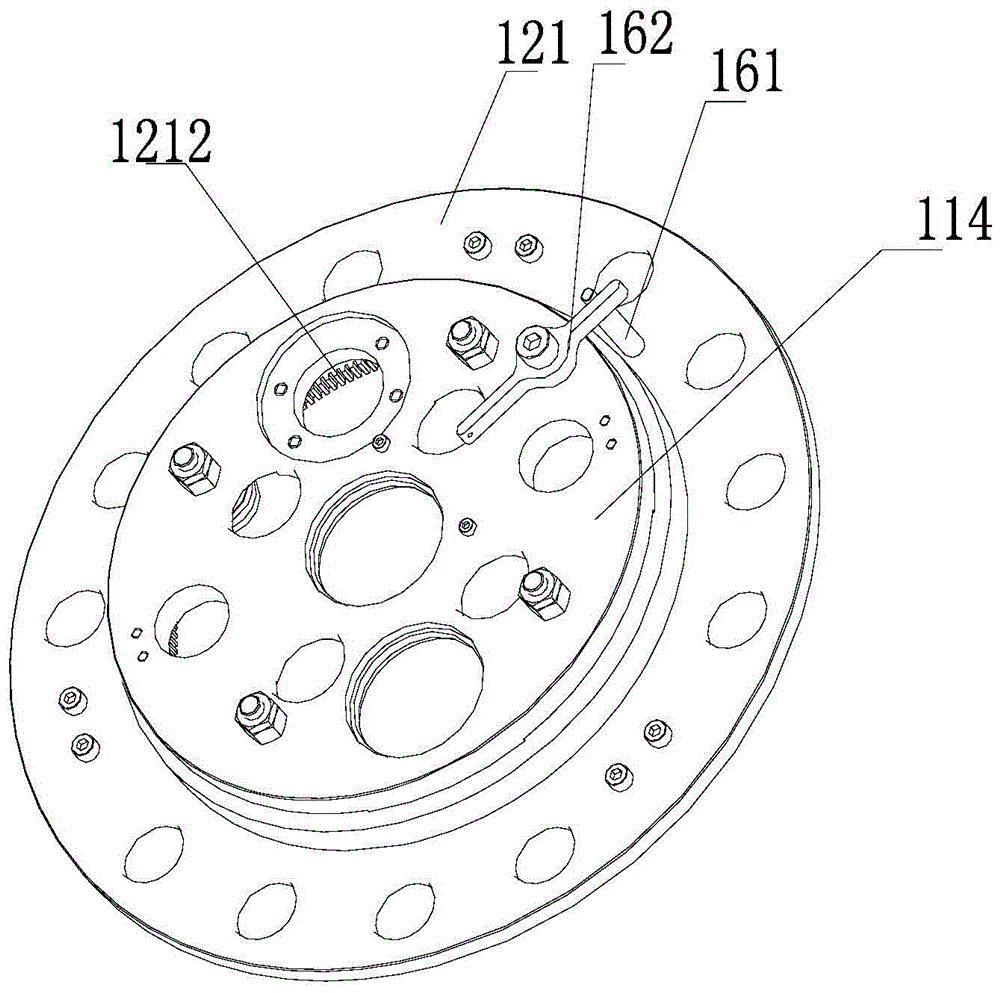

[0024] like figure 1 , 2 As shown, the outer wall inspection device 1 includes an adaptive mechanism 14 for installing and enabling the eddy current probe 4 to always be in close contact with the penetrating piece 5 and the bottom head 6 when it rotates around the penetrating piece 5, and drives the self-adaptive mechanism 14. The first axial driving mechanism 11 for the mechanism 14 to move axially along the penetrating member 5, the first circumferential driving mechanism 12 for driving the self-adaptive mechanism 14 to move circumferentially al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com