Combine harvester threshing cylinder assembly

A technology of combine harvester and thresher, which is applied in the direction of harvester, threshing equipment, cutter, etc., can solve the problems of grain entrainment, stem grass discharge, large harvest loss rate, large threshing gap, etc., and achieves low cost and detachment efficiency. High, good detachment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

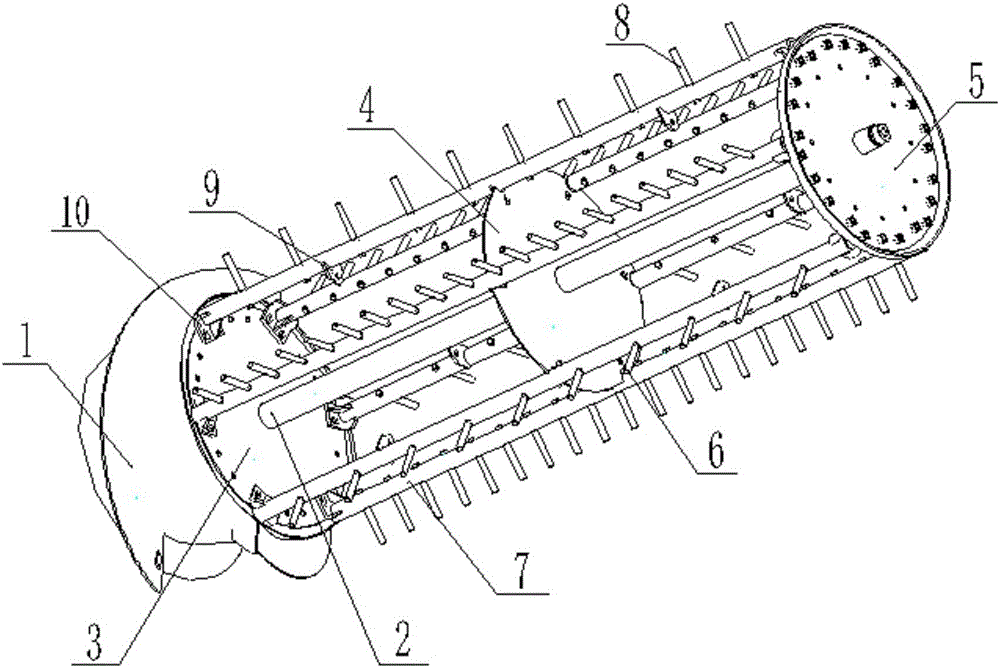

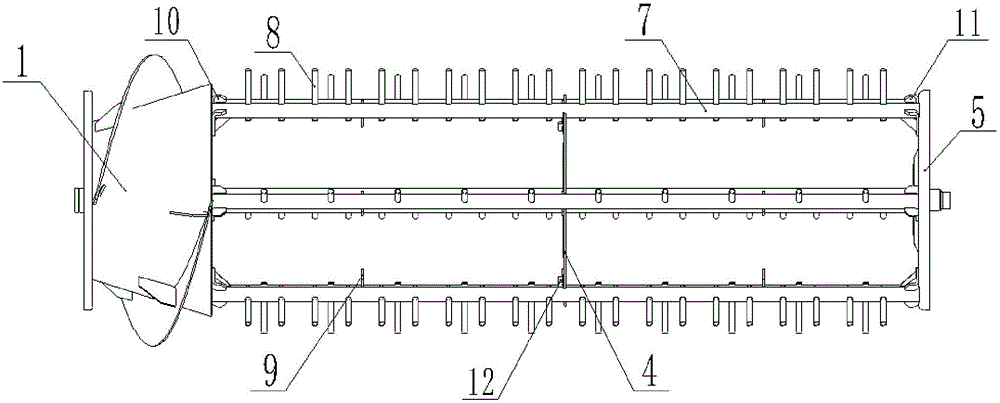

[0017] Such as figure 1 and figure 2 As shown, it shows a specific embodiment of the present invention, a combine harvester threshing cylinder assembly, including a front assembly 1, a main shaft 2, a front main shaft connecting plate 3, a middle main shaft connecting plate 4, and a rear main shaft connecting plate 5 , mounting hole 6, connecting rod 7, batting teeth 8, mounting piece 9, front mounting seat 10, rear mounting seat 11 and bolt 12, the front assembly 1 is fixedly installed on the front main shaft connecting plate 3, the front assembly 1 The outer surface is provided with spiral blades, and the spiral blades are provided with reinforcing ribs. The front end of the main shaft 2 is fixedly installed in the mounting hole of the front assembly 1, and its rear end is fixedly installed in the center hole of the rear main shaft connecting plate 5. The connecting rod 7 is radially installed with several batting teeth 8, the front mounting base 10 is fixedly installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com