Automatic deboning machine for fowl sole products and fowl sole deboning method

A deboning machine and poultry technology, applied in poultry deboning, poultry processing, slaughtering, etc., can solve the problems of difficult boneless chicken feet and low industrial efficiency, and achieve simple and effective operation, improved industrial efficiency, and thorough bone removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

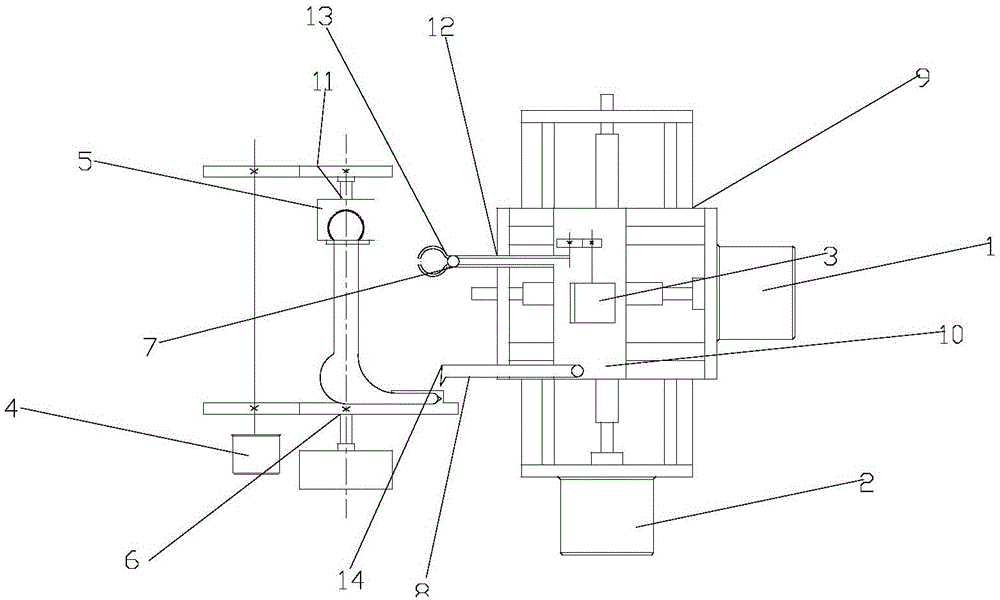

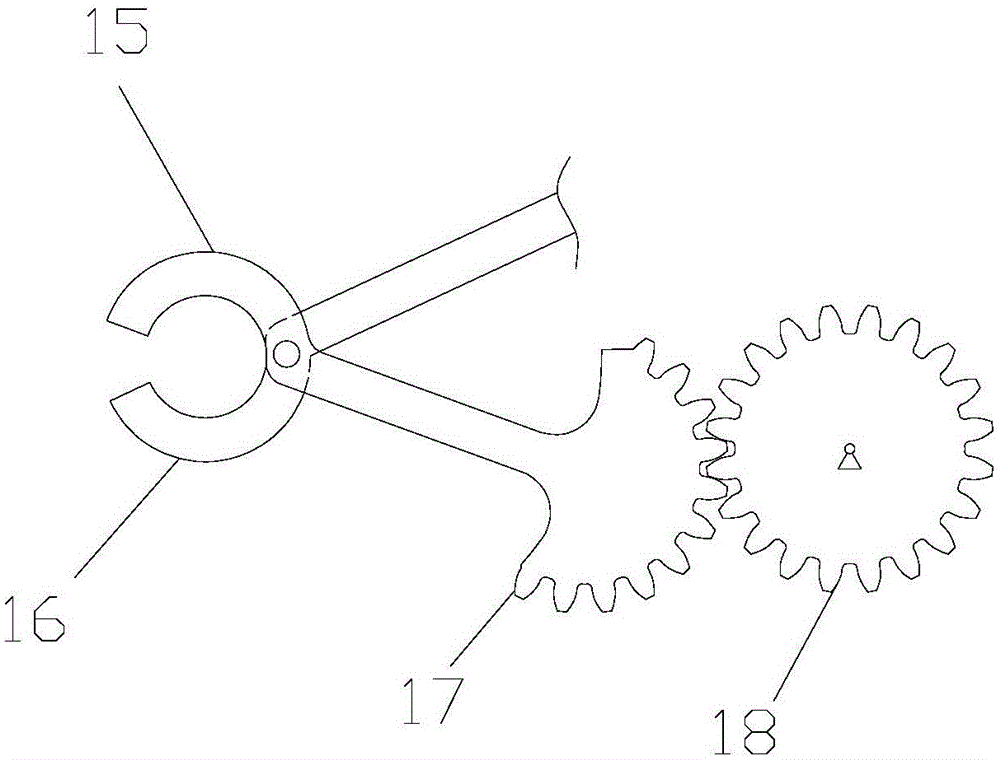

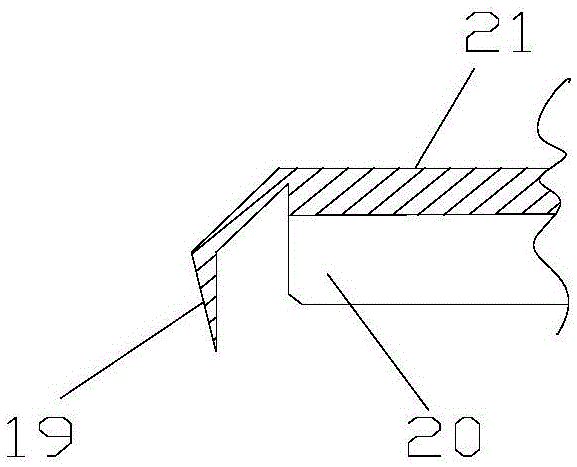

[0027] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the automatic deboning machine for poultry paw products in this embodiment includes a clamp for fixing poultry paws and a deboning cutter for cutting chicken feet bones and for driving the The driving assembly that the deboning cutter assembly moves; the deboning cutter includes a small phalanx bone removal cutter 8 for removing the small phalanx of the chicken paw, and the small phalanx bone removal cutter 8 includes a bone removal cutter body 21 and is fixed on the bone removal cutter The body 21 is used to cut off and pull out the lesser phalanx of the chicken claw. The automatic deboning machine for poultry paw products in this embodiment uses a clamp to keep the poultry foot in a standing state, and then uses the drive assembly to drive the lesser phalanx bone removal tool 8 Cut the little phalanx in the vertical direction, after using the transverse blade 19 to cut off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com