Numerically-controlled groove planing machine for cutting V-shaped groove in metal sheet

A technology for sheet metal and planing machines, which is applied in the direction of planing machines, metal processing machinery parts, metal processing equipment, etc., can solve the problems such as the inability to realize slotting, achieve precise knife advance and retreat movements, and ensure the depth of V-shaped slots Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

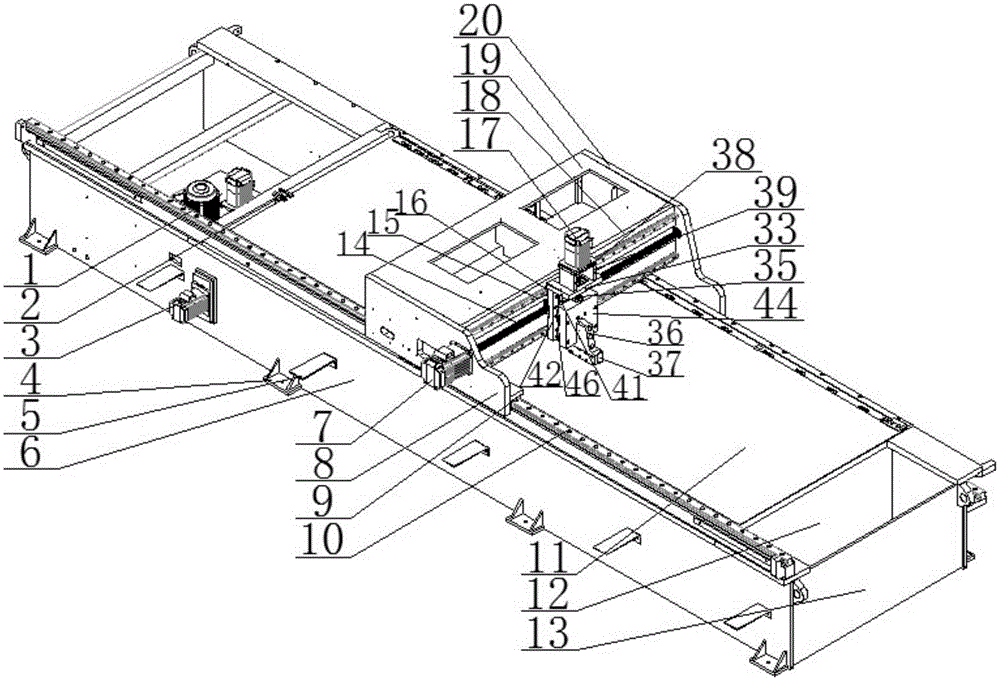

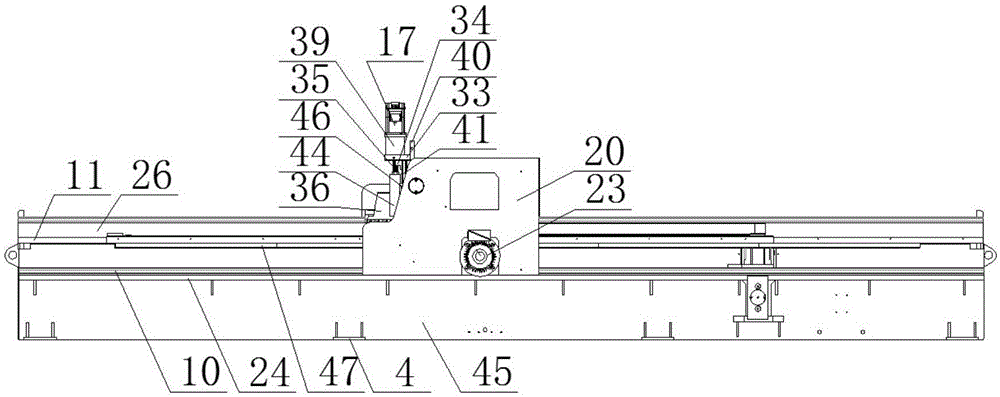

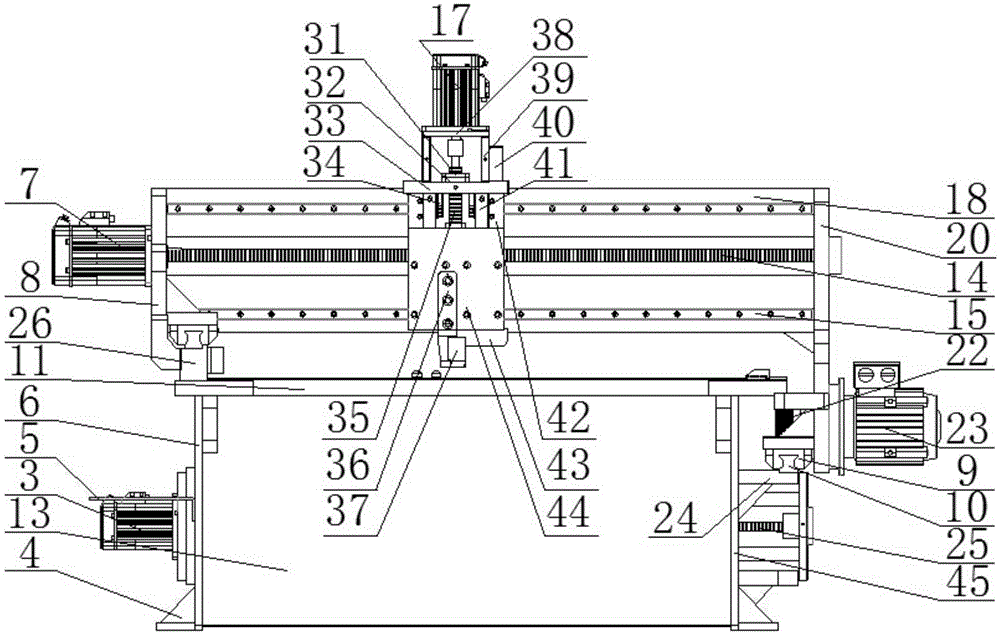

[0017] A kind of V-groove CNC planer for thin metal plate, such as Figure 1-5 As shown, it is composed of the base part, the upper frame part, the knife rest part and the sheet metal presser foot assembly. The base part is composed of the base side plate a6, the base side plate b45, the bottom head plate 13, the foot iron 4, and the workbench The plate 11 constitutes a box-type base, and the foot iron 4 is fixed on the ground to fix the base through anchor bolts, and the line rail a10 is respectively installed on the line rail a track seat plate a 24 and the line track a track seat plate b 26, and the rear of the base The hydraulic and pneumatic workstation 1 is installed at the end, the front end of the base is provided with a waste box 12, and a rack 47 is installed under one side of the worktable 11; The b track seat plate 18 and the upper frame bottom plate 23 are composed of the upper frame side plate a20 and the upper frame side plate b8, and the line track a slider 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com