Concrete slab lifting system

a technology of concrete and lifting system, which is applied in the direction of lifting devices, foundation engineering, buildings, etc., can solve the problems of inability to work with the slab below, no support for the jack to prevent toppling, and inapplicability of the suspension mechanism of the prior ar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

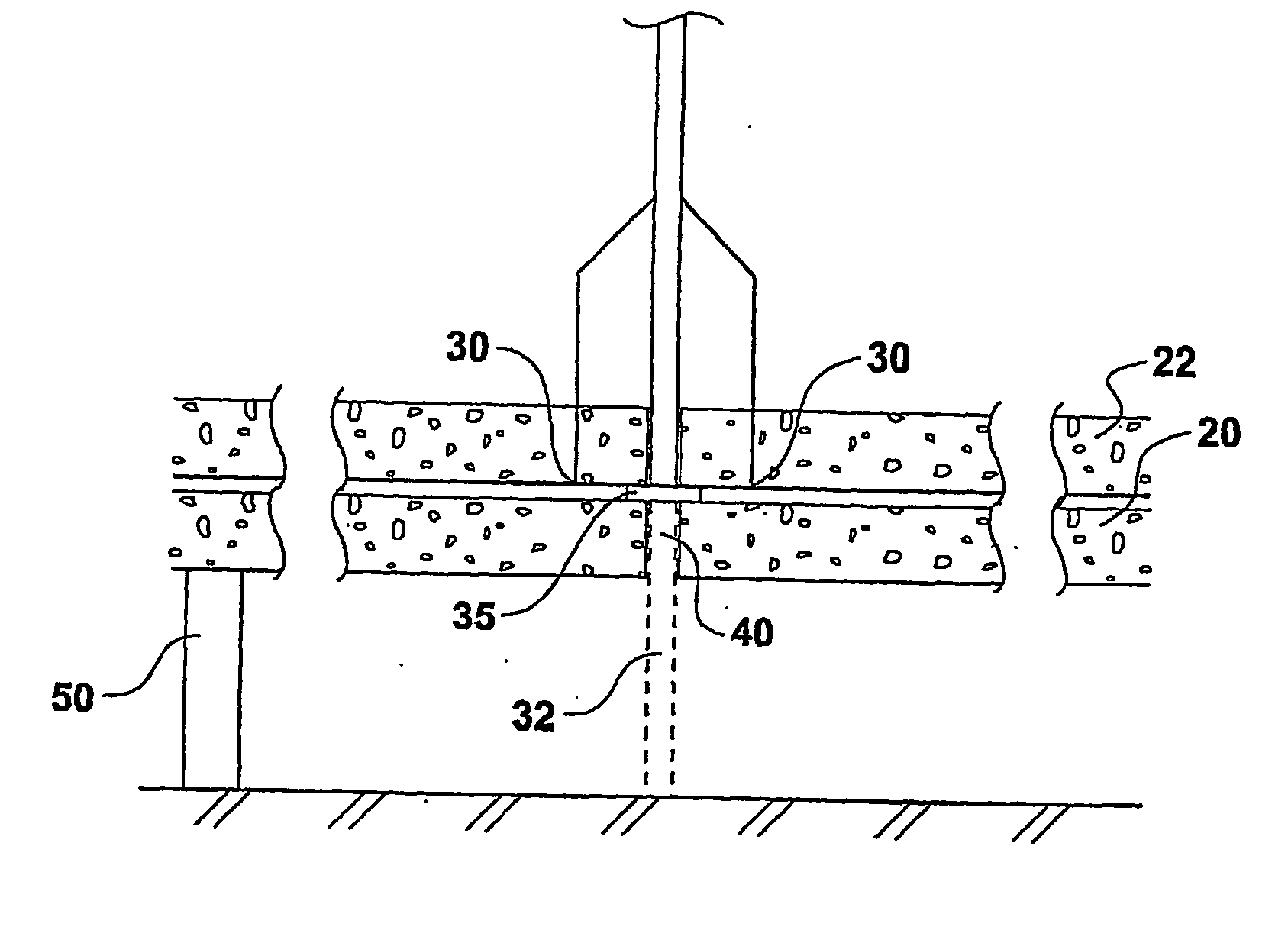

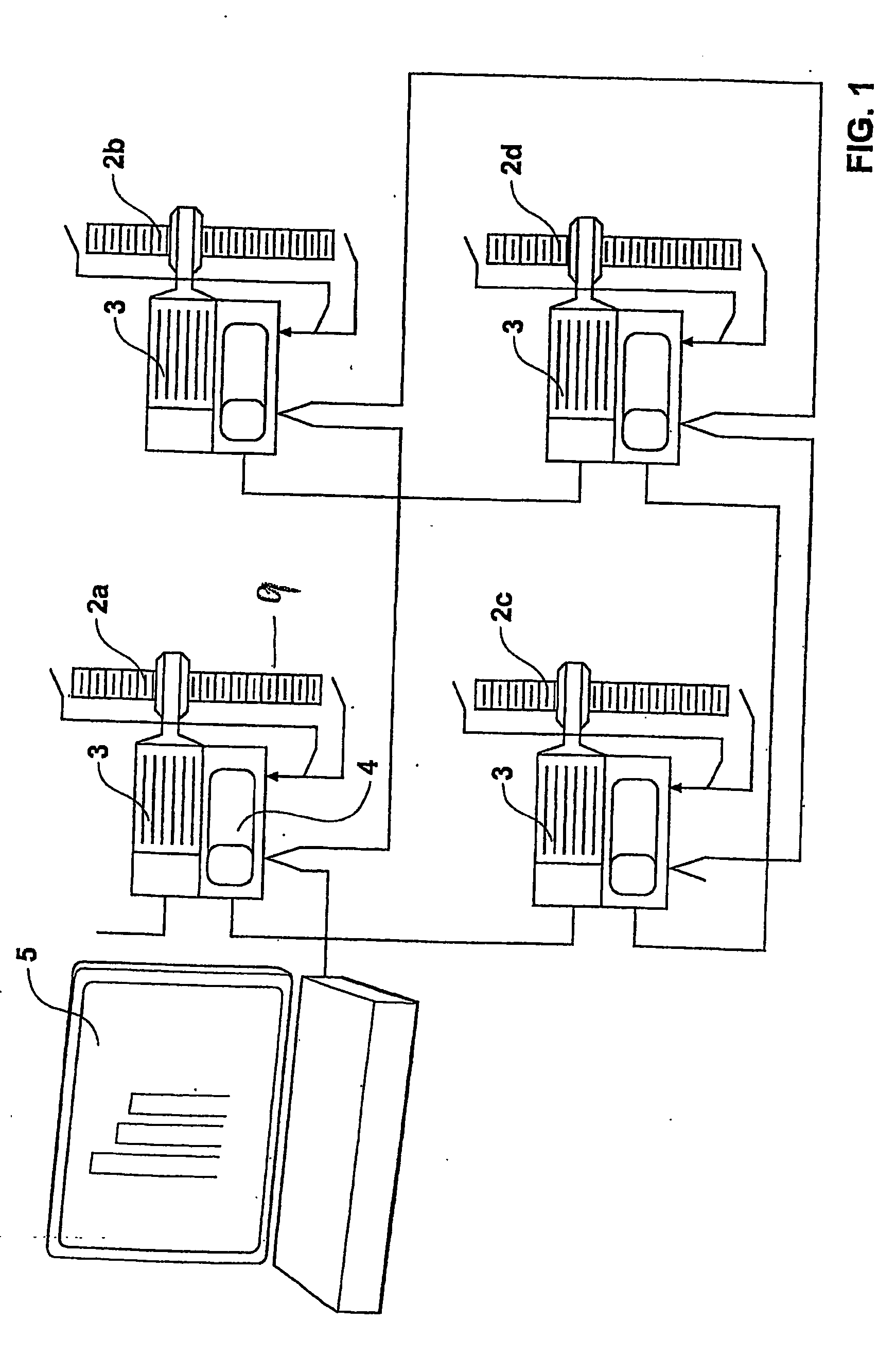

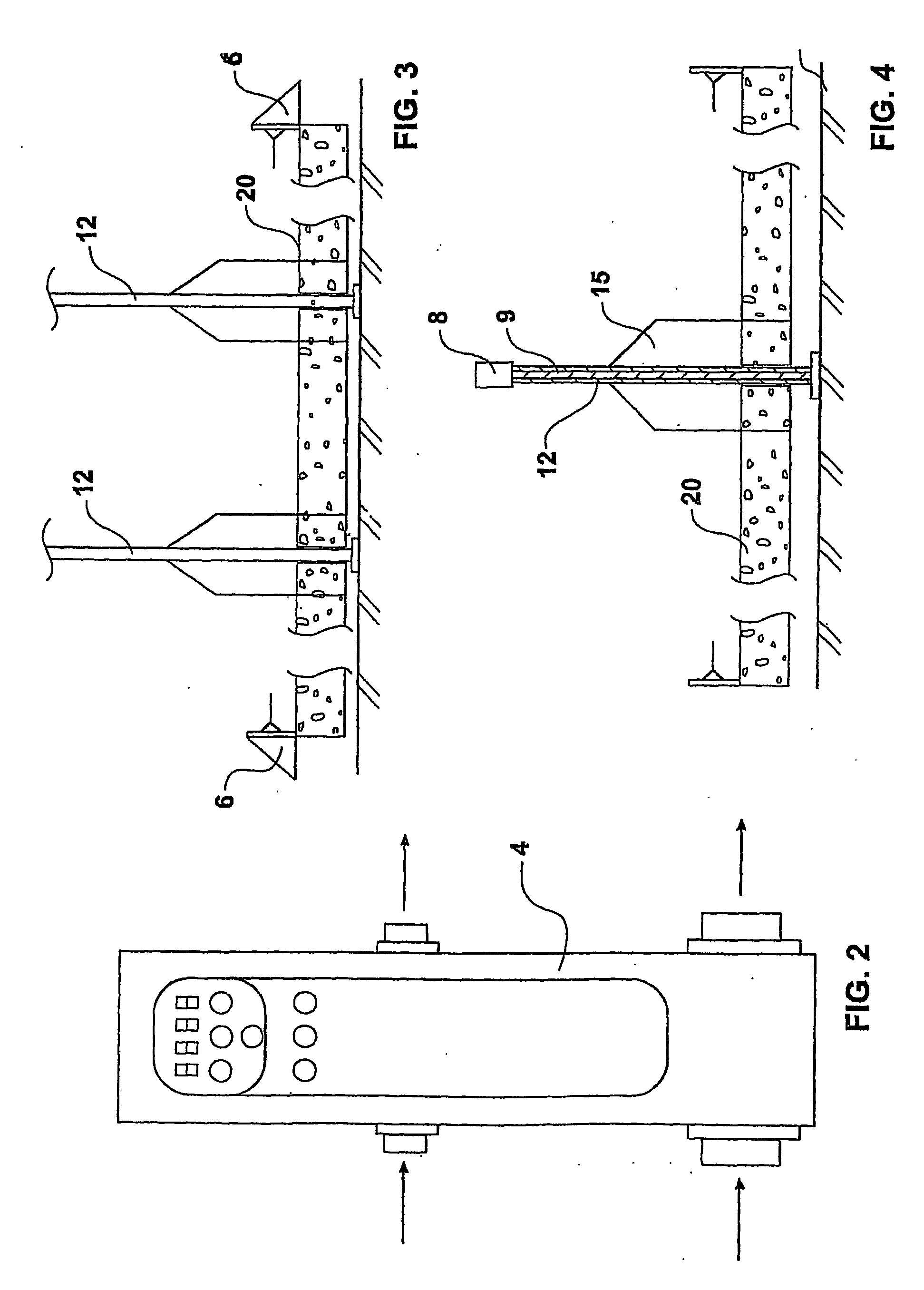

[0095] The invention can be understood by reference to FIGS. 1 to 16 whereby in summary FIGS. 1-10 show the synchronised system, FIG. 11 shows the jack and FIGS. 12-16 show the scaffolding system. The following numbering sequence for FIGS. 12-16 are to be considered separately, from the other figures.

[0096] For simplicity only four jacks 2A-2D are shown connected to a central computer 5. Each jack is a screw jack driven by an electric motor 3, which is controlled by variable speed drive 4. Typically each motor can be a 0.75-1.5 kW, four pole, 50 Hz, flange mounted 400 volts, brake motor. Each motor 3 will be driven by a three phase power supply typically 400 volts at 100 amps. Each motor is controlled by a central computer 5.

[0097] The system can provide a synchronised position control through a system controller of a number of motors 3. One control parameter is position synchronisation between all the jacks. This makes use of variable speed control of the individual jack motors, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com