Small and medium-sized internal high pressure forming machine for bulging pressure pulsation loading

A technology of internal high pressure forming and pressure pulsation, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as inability to realize pulsation loading, and improve energy utilization efficiency and stability , The effect of reducing the installed power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

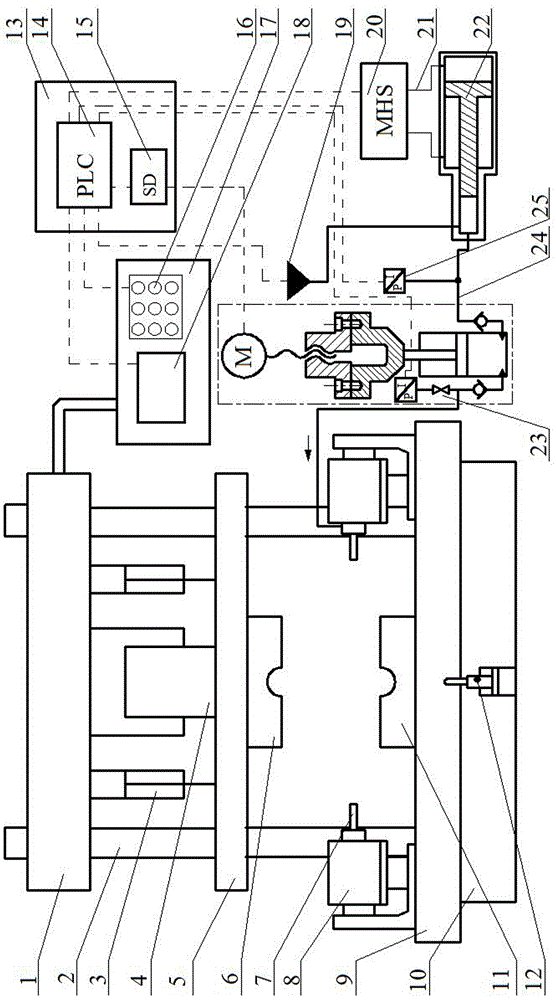

[0036] This embodiment is internal high pressure forming with conventional linear loading of bulging pressure, combined with Figure 1-6 This embodiment will be described.

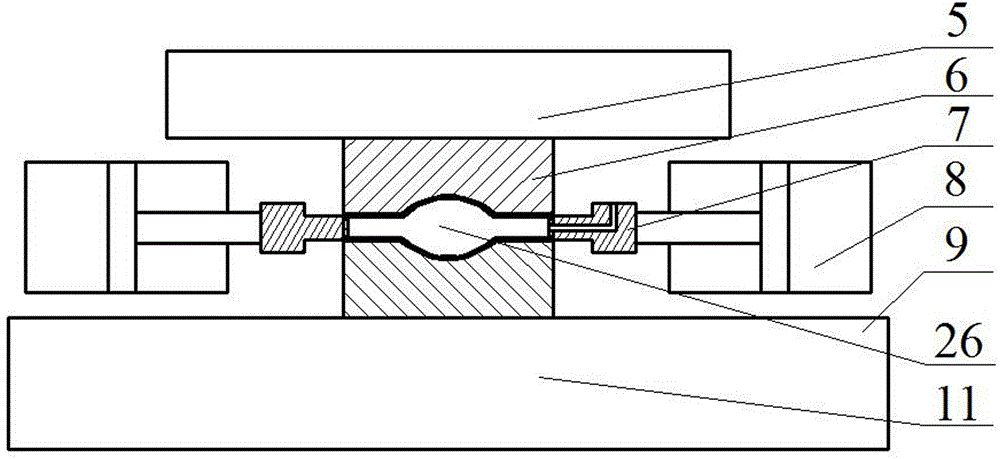

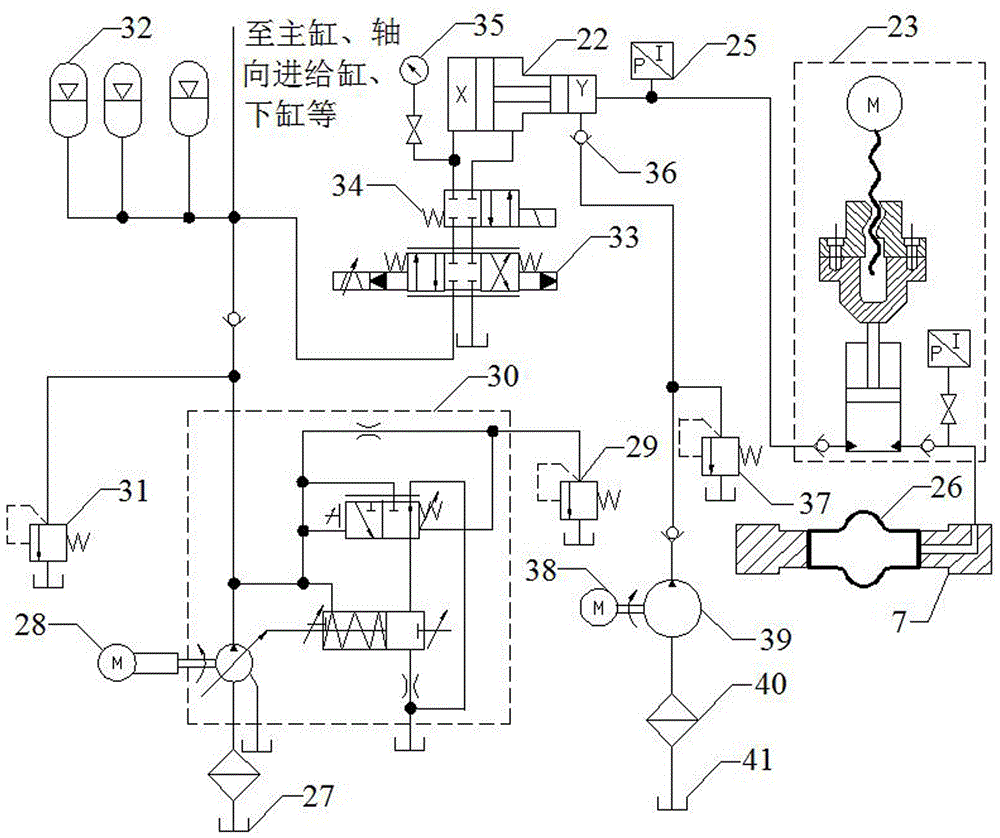

[0037] A small and medium-sized internal high pressure forming machine with bulging pressure pulsation loading according to the present invention, comprising: an upper beam 1, four guide columns 2, two fast cylinders 3, a main cylinder 4, a movable beam 5, an upper mold 6, two (or three) axial feed cylinder 8 and the same number of punches 7, workbench 9, frame 10, lower die 11, lower cylinder 12, electrical control cabinet 13, PLC (including AD / DA module) 14. Servo driver 15, multiple button switches 16, control panel 17, touch screen 18, low-pressure liquid filling system 19, host hydraulic system 20, system oil pipe 21, booster cylinder 22, pulsation hydraulic pressure generating device 23, high-pressure water pipe 24, pressure Transmitter 25.

[0038] The pulsation hydraulic pressure generating devic...

Embodiment 2

[0056] This embodiment is internal high pressure forming with sinusoidal pulsation loading of bulging pressure, combined with Figure 1-7 This embodiment will be described.

[0057] In this embodiment, the internal pressure loading curve function is:

[0058] P 1 (t)=P 0 (t)+ΔP·sin(2πω·t).

[0059] In the formula, P 0 (t) is the conventional linear loading curve in Example 1, ΔP is the pulse wave amplitude, which is 5 MPa in this embodiment; ω is the pulse frequency, which is 1 Hz in this embodiment.

[0060] Compared with Example 2, the pulsating loading method is selected as 1, and the amplitude h needs to be manually measured before the part is formed. Because the system only feeds back and controls the conventional linearly loaded pressure, the pulsating pressure is partially open-loop controlled, and the input program is the amplitude h of the piston rod of the pulsating cylinder, not the amplitude ΔP of the pulsating pressure. Knowing the hydrodynamic properties of...

Embodiment 3

[0065] This embodiment is internal high pressure forming with rectangular pulsating loading of bulging pressure, combined with Figure 1-9 , Figure 8 This embodiment will be described.

[0066] In this embodiment, the internal pressure loading curve function is:

[0067]

[0068] In the formula, P 0 (t) is the conventional linear loading curve in Example 1, ΔP is the pulse wave amplitude, which is 5 MPa in this embodiment; ω is the pulse frequency, which is 1 Hz in this embodiment.

[0069] Compared with Embodiment 2, the servo motor 49 drives the piston rod 46 to move at the maximum rotational speed in each pulsation period. The piston rod 46 moves quickly from the balance point to the maximum amplitude h, pauses for a period of time, then descends to the position h below the balance point, and quickly returns to the balance point when the pause is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com