Electronically controlled linear pump drive actuator

An actuator and linear technology, applied in the direction of electric components, pumps, pump control, etc., can solve the problems of reducing accuracy, reducing the accuracy of rotational inertia, reducing the accuracy of dose adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

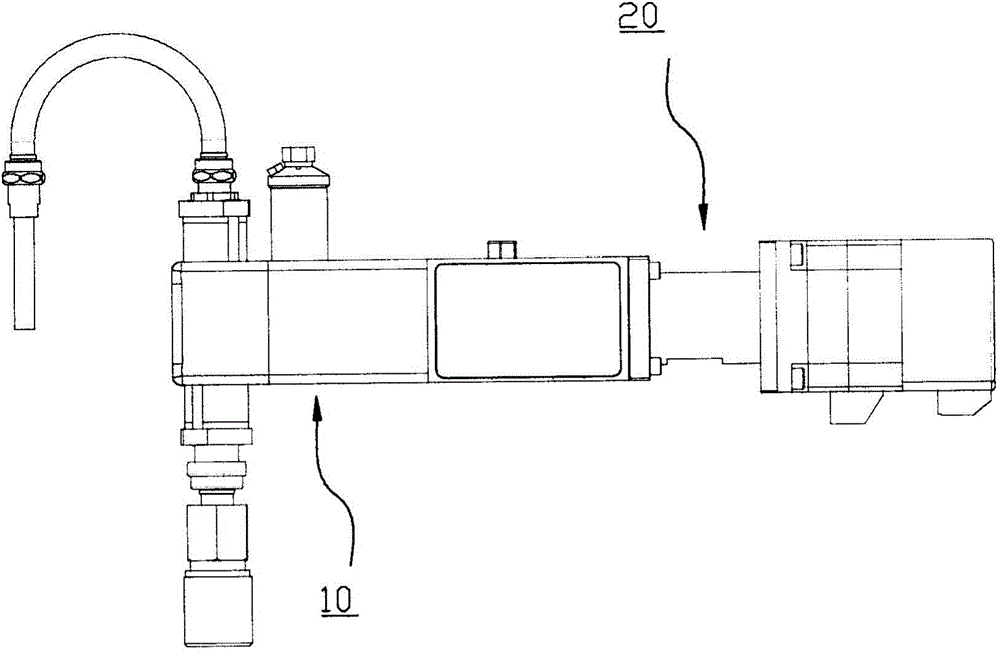

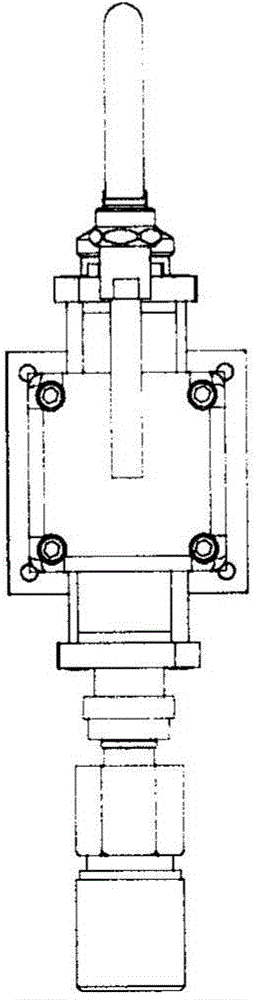

[0046] exist figure 1 In and 2, as mentioned above, a prior art metering pump is shown with a 2S servo motor drive commercially available from Hibar Systems Limited of Richmond Hill, Canada. The pump has an footprint of 12.90 x 2.36 inches [327.6 x 59.9 mm] with the pump head assembly making up the dispensing unit 10 being 4.00 inches [101.6 mm] long and the servo motor driven linear actuator 20 being 8.90 inches [226.1 mm] long. In order to operate the pump, the power controller and electronic controller must be located externally, which is accomplished by connecting the rear end of the pump with cables to an external control box of comparable size and weight.

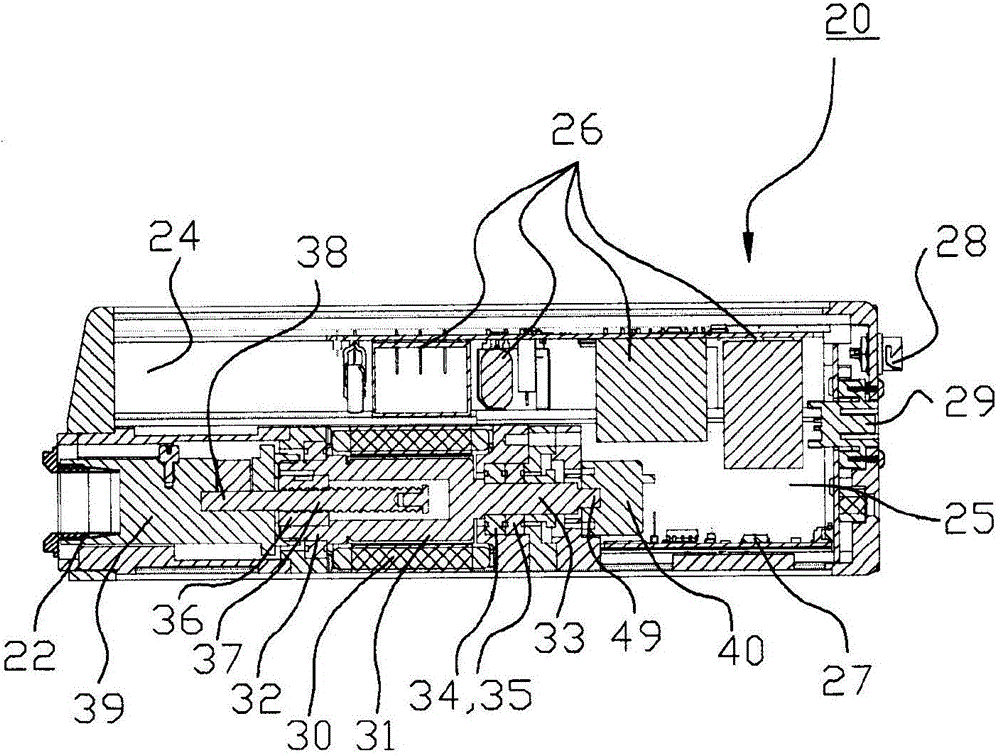

[0047] Figures 3 to 5 There are shown cross-sectional, front and perspective views of a preferred embodiment of a linear actuator 20 according to the present invention, which may also be referred to as an integrated servo motor driven pump (ISP) drive. The actuator 20 has a generally rectangular elongated housing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com