Fast High Precision Positioning Unit

A positioning unit, high-precision technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of consuming a lot of time, not on the same plane, and the detection aids cannot be positioned accurately, so as to achieve easy assembly and disassembly, and fast installation , The effect of saving assembly and disassembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] In the machinery manufacturing industry, for the processing or measurement of box and cover parts, the conventional positioning method is two pins on one side, one of which is the main positioning pin, and the main positioning pin is usually not only the design basis of the product, but also the processing and measurement benchmark. The positioning accuracy of the main positioning pin is directly related to the measurement accuracy and processing accuracy. The fast and high-precision positioning unit of the present invention is a non-independent component mechanism, which is suitable for being fixed on a measuring fixture plate or a machined fixture plate and used as a main positioning pin.

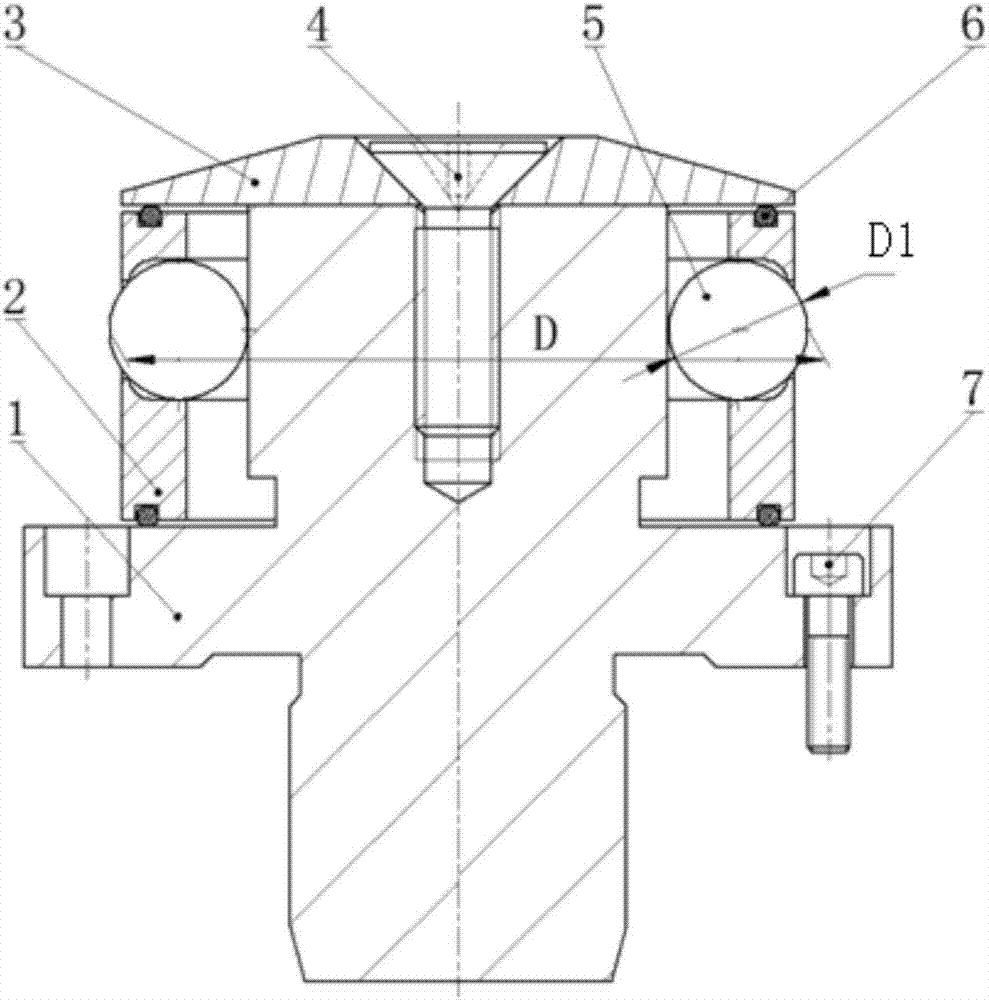

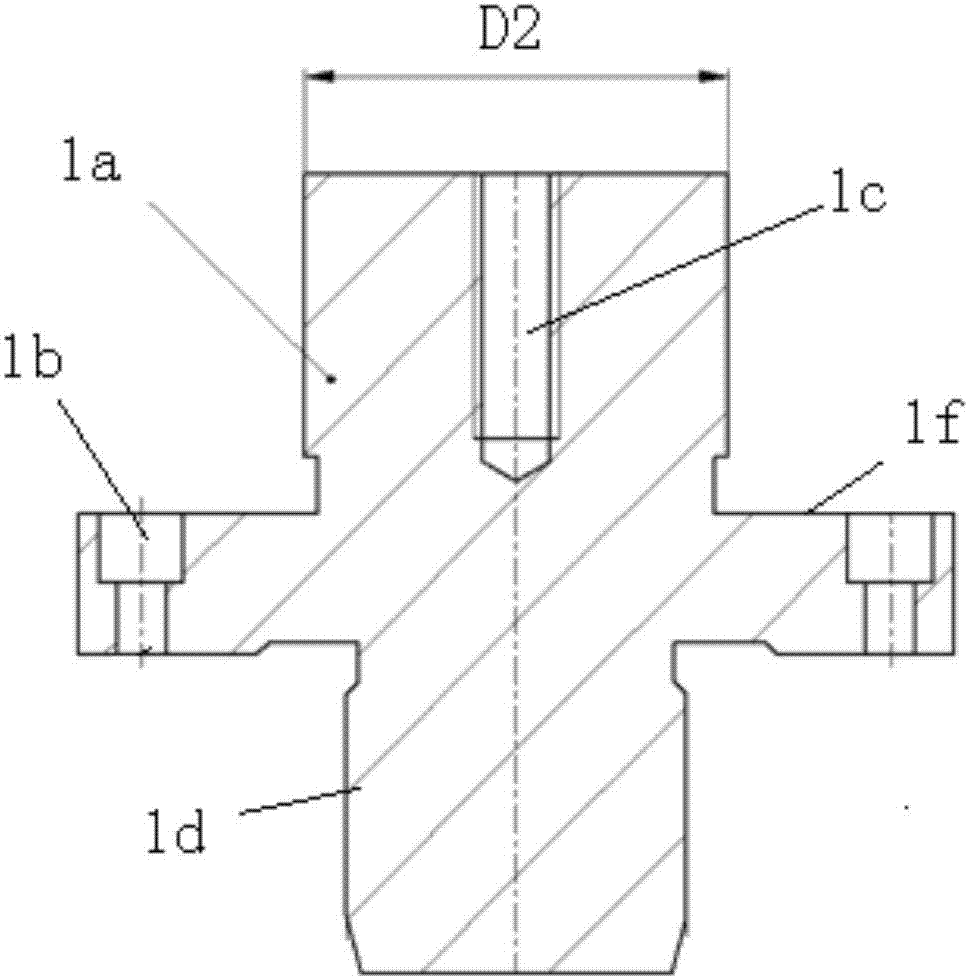

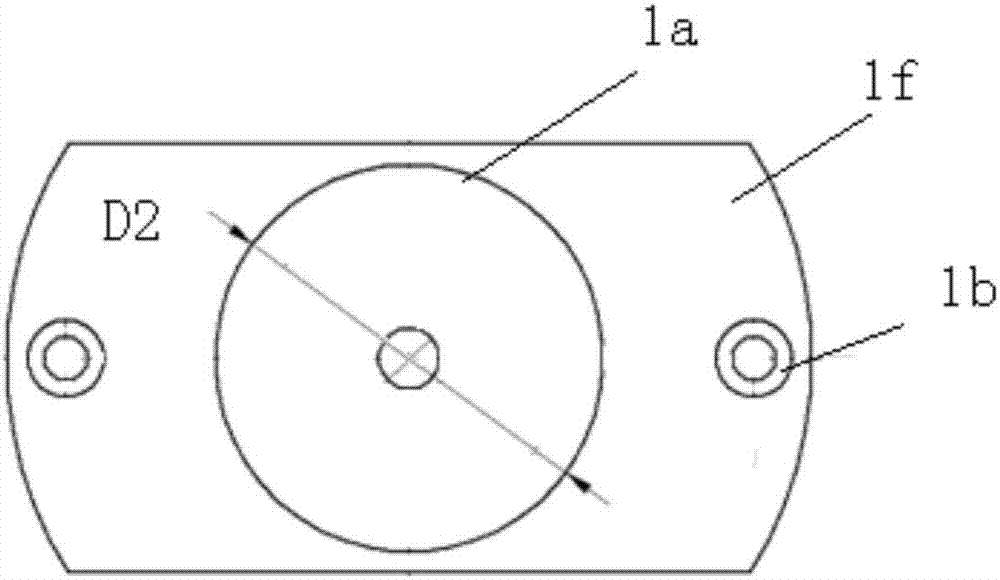

[0029] like Figure 1 to Figure 6 The fast and high-precision positioning unit shown includes a mandrel 1, a sheath 2, a pan head screw 7 and a plurality of steel balls 5 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com