Magnetic field generator of magnetorheological polishing equipment

A magnetic field generating device and magnetorheological polishing technology, which is applied to magnets, magnetic objects, electrical components, etc., can solve the problems of small polishing area and inability to complete complex curved surface polishing, and achieve high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

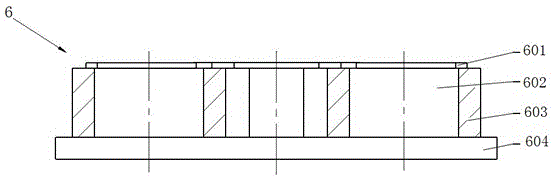

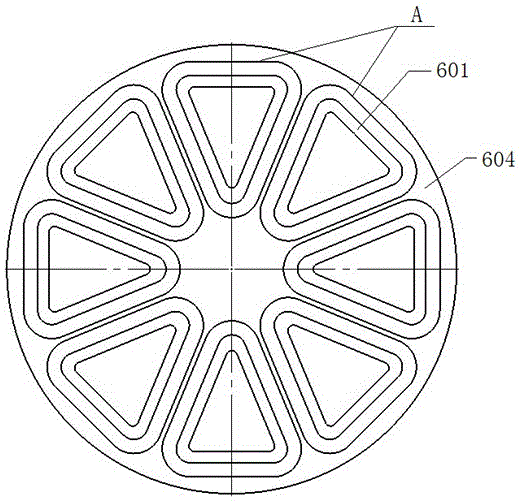

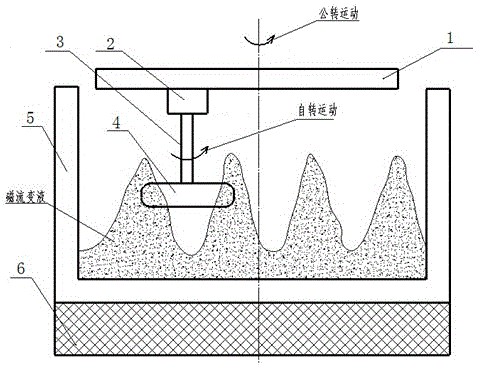

[0020] See figure 1 , figure 2 The magnetic field generating device 6 provided by the present invention adopts a plurality of electromagnetic pole groups A capable of generating a gradient magnetic field, and the electromagnetic poles constituting the plurality of electromagnetic pole groups A adopt a triangular shape arranged in a ring and the polarities of two adjacent magnetic poles are opposite. Magnetic poles, each electromagnetic pole group A is composed of two magnetic poles with opposite polarities, each magnetic pole includes a triangular magnetic core 602, a triangular annular pole head 601 installed on the magnetic core 602, and a magnetic core coil 603 wound on the magnetic core 602 , The magnetic core 602 and the magnetic core coil 603 are integrally installed on a bottom plate 604, and an air gap with a distance of 10-20 mm is provided between two adjacent magnetic poles, preferably an air gap of 15 mm.

[0021] The magnetic field generating device 6 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com