Small high-power relay

A high-power relay, small-scale technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of leakage of sealing materials into relays, reduction of withstand voltage of contacts and coils, reduction of creepage distance, etc., to achieve reliability Improvement, the number of ampere-turns increases, and the effect of increasing the creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

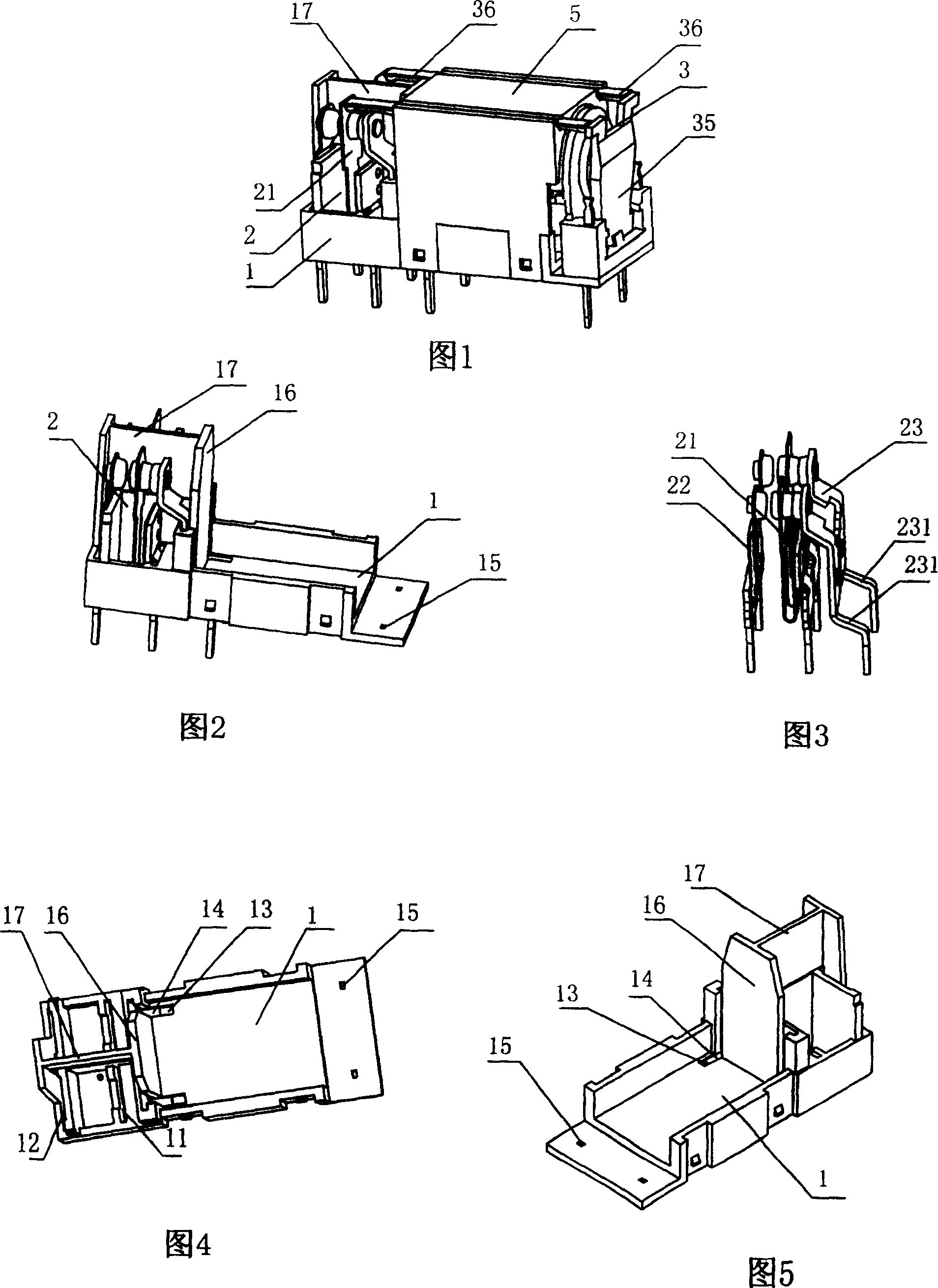

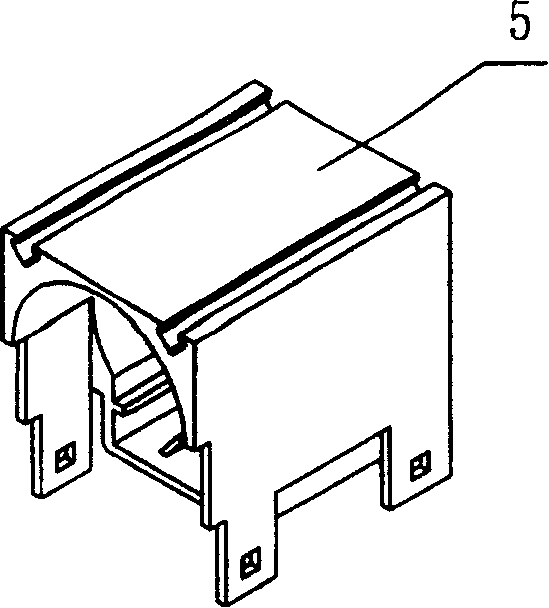

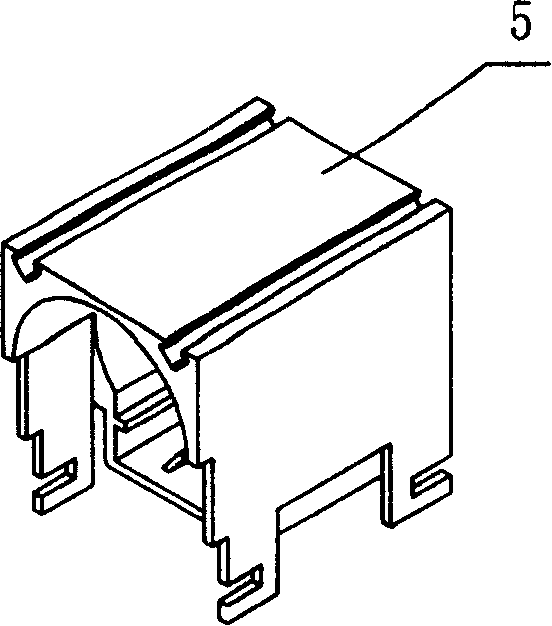

[0026] Embodiment 1: A small high-power relay, including a base 1, a contact system 2, a magnetic circuit system 3 and a case 4, and the contact system 2 includes a moving contact piece 21, a normally open static contact piece 22 and a normally closed static contact piece 23 , the base 1 is correspondingly provided with a moving contact jack 11, a normally open static contact jack 12 and a normally closed static contact jack 13, and the magnetic circuit system 3 includes a coil 31, a lead piece 32, an iron core 33, and a yoke 34 And the armature 35, the armature 35 is connected with the moving contact piece 21 through the push rod 36, the magnetic circuit system 3 is provided with an insulating cover 5, the combination of the coil 31 and the yoke 34 is arranged in the insulating cover 5, and the normally closed static contact piece jack 13 is provided with a contact groove 14 extending along the upper bottom surface of the base 1, the lower part of the normally closed static co...

Embodiment 2

[0027] Embodiment 2: Other structures are the same as Embodiment 1, except that the contact system 2 includes a set of changeover contacts, and the insulating partition 16 is not provided with a vertical and integrally connected auxiliary insulating partition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com