a jig head

A fixture head and integrated technology, applied in the direction of manufacturing tools, workpiece clamping devices, electrolysis process, etc., can solve the problems of affecting the service life of the fixture head, increasing the operating cost of the enterprise, and corrosion of the fixture head, so as to achieve a simplified structure and high production efficiency , reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

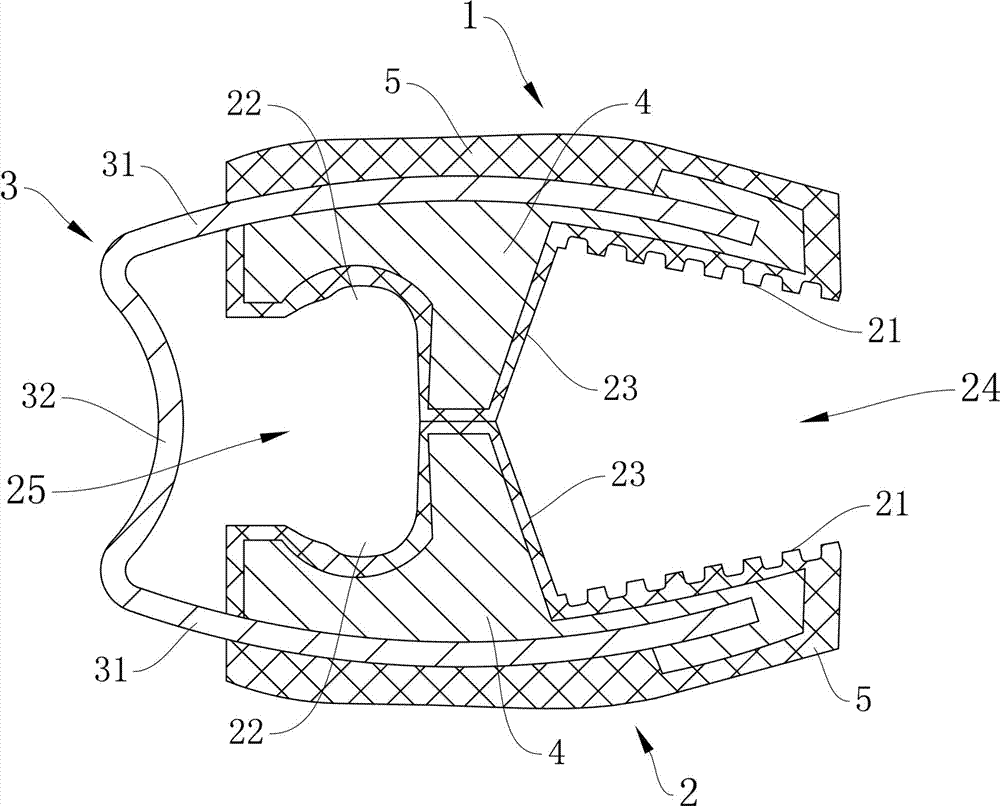

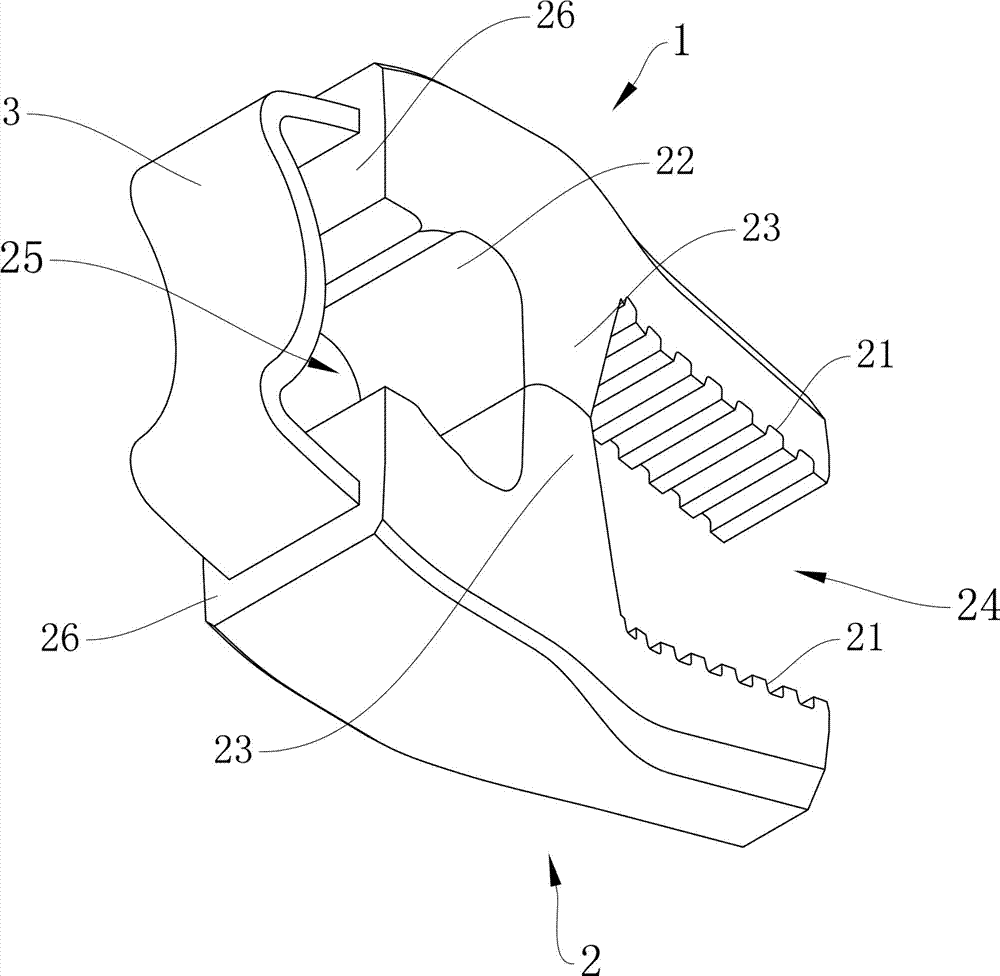

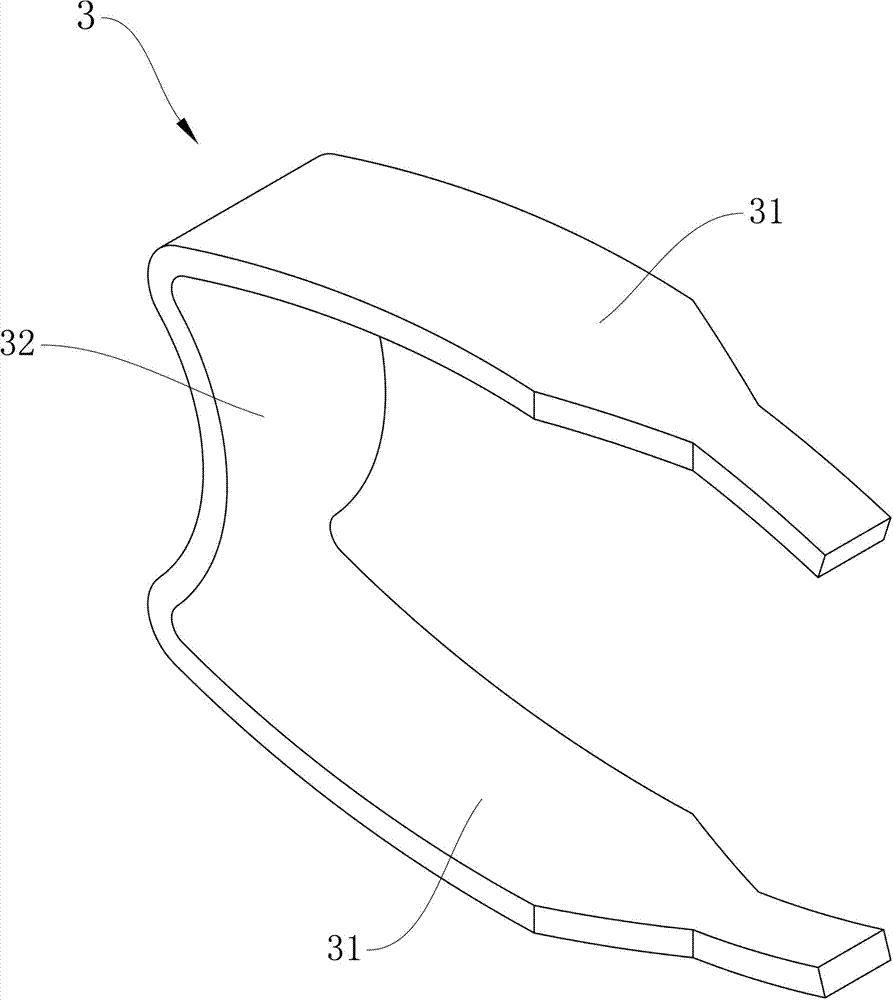

[0019] A class is, for example Figure 1 to Figure 6 As shown, the elastic tension connector 3 is composed of two connection parts 31 and an elastic tension part 32 disposed between the two connection parts 31 . Among them such as Figure 4 As shown, the elastic tensioning portion 32 is formed with an inwardly concave arc concave surface 30, and an outwardly arched arc transition portion is also formed at the connection between the elastic tensioning portion 32 and the two connecting portions 31 40, the two connecting parts 31 are respectively bent into an arc-shaped shape 50 that is relatively outwardly arched. Through such a structural design, the left clamping assembly 1 and the right clamping assembly 2 can obtain better tension elasticity, and are more reliable and firm when clamping objects. On the basis of this scheme, according to the different cross-sectional shapes of the connecting part 31 and the elastic tension part 32, two schemes can be extended: one is imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com