Bookshelf Pneumatic Constant Pressure Machine

A pneumatic, constant pressure machine technology, applied in the direction of lamination, lamination devices, layered products, etc., can solve the problem of uncontrollable pressure, can only be placed on one working surface, and the efficiency of pressurization, curing and shaping is low and other problems, to achieve the effect of convenient reset, easy and precise positioning, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

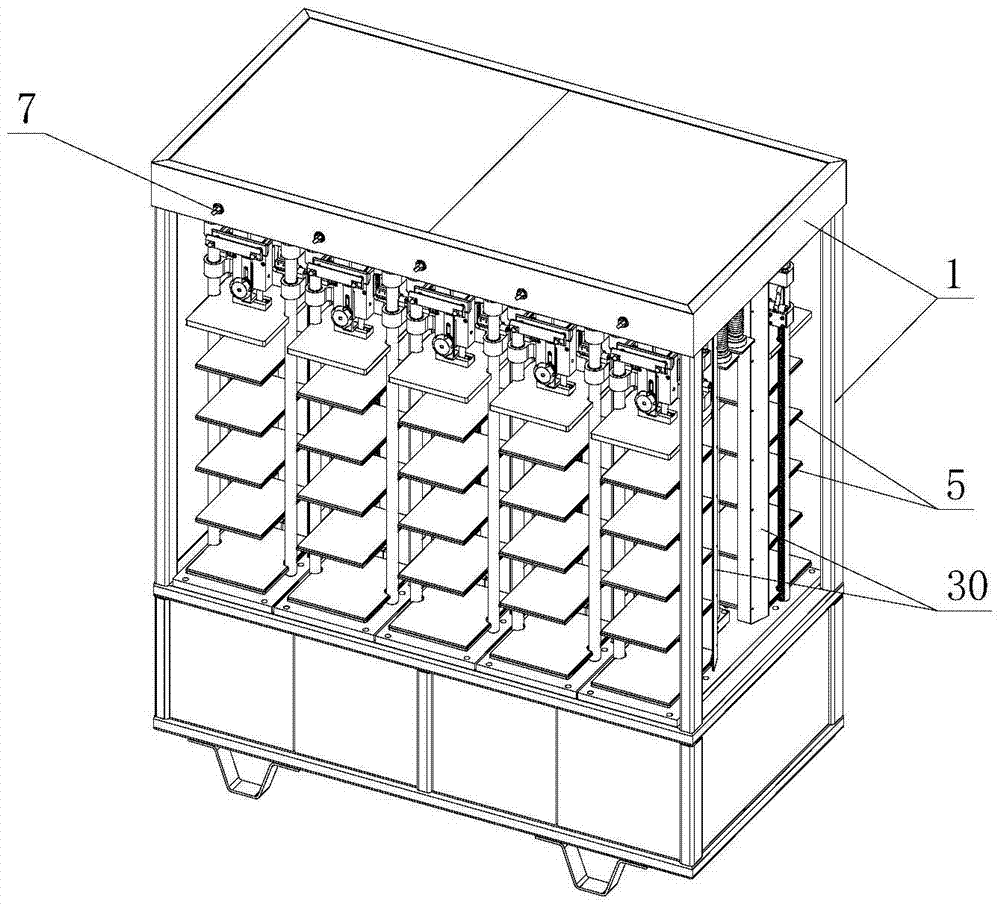

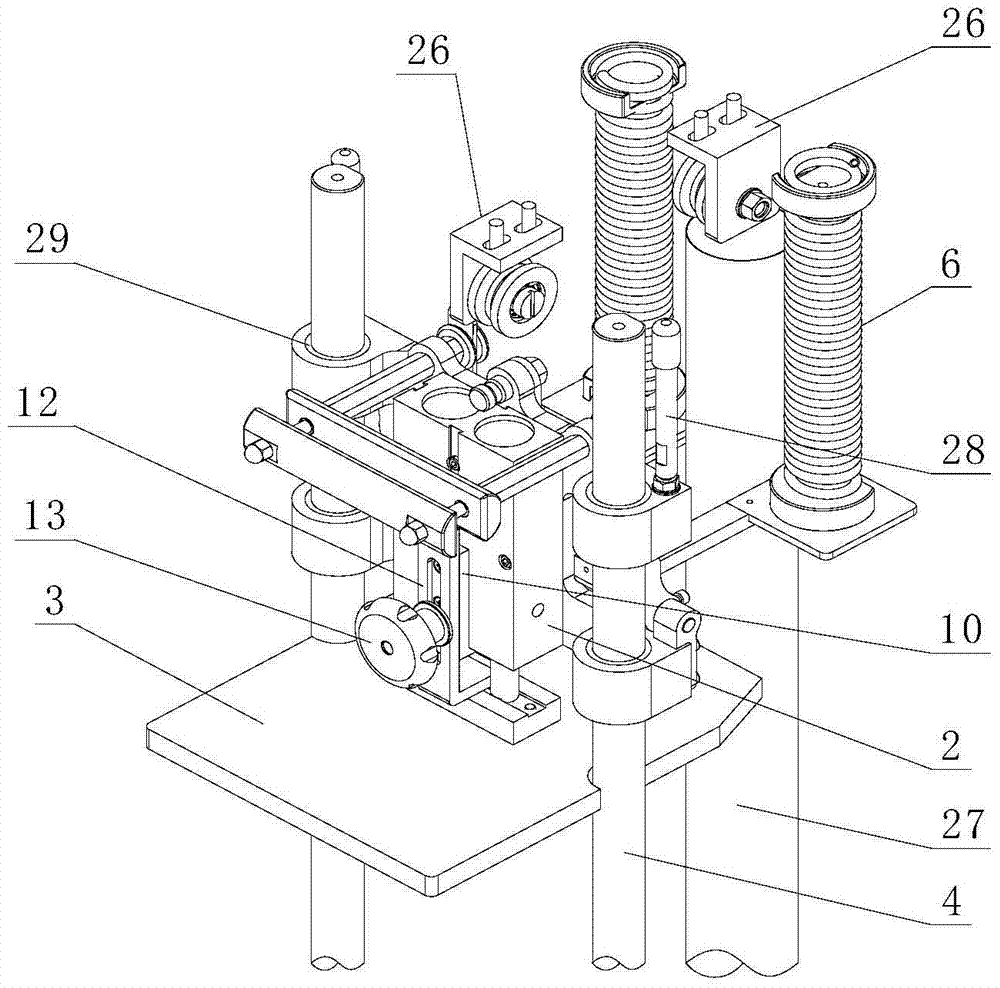

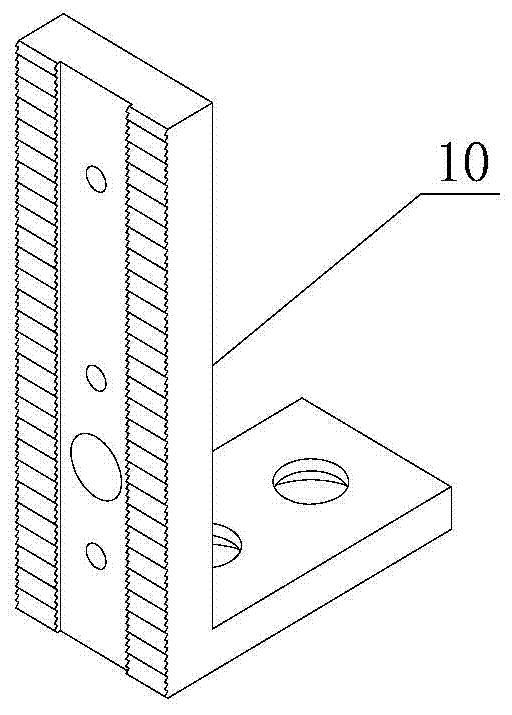

[0021] Such as Figure 1~6 A bookshelf-type pneumatic constant pressure machine shown includes a bookshelf-type frame body 1, and two rows of flattening machine units arranged side by side and opposite to each other are installed in the frame body. Each flattening machine unit includes a cylinder 2, a connecting An air pressure plate 3 for pressing paper products under the movable end of the cylinder 2 and a guide shaft 4 vertically installed on the frame body 1 to guide the flatter unit to move up and down.

[0022] The bookshelf-type pneumatic constant pressure machine has a first locking mechanism that lowers the flattener unit and initially presses and locks the paper product.

[0023] The first locking mechanism includes a ratchet provided on the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com